Originally posted by loekaaz

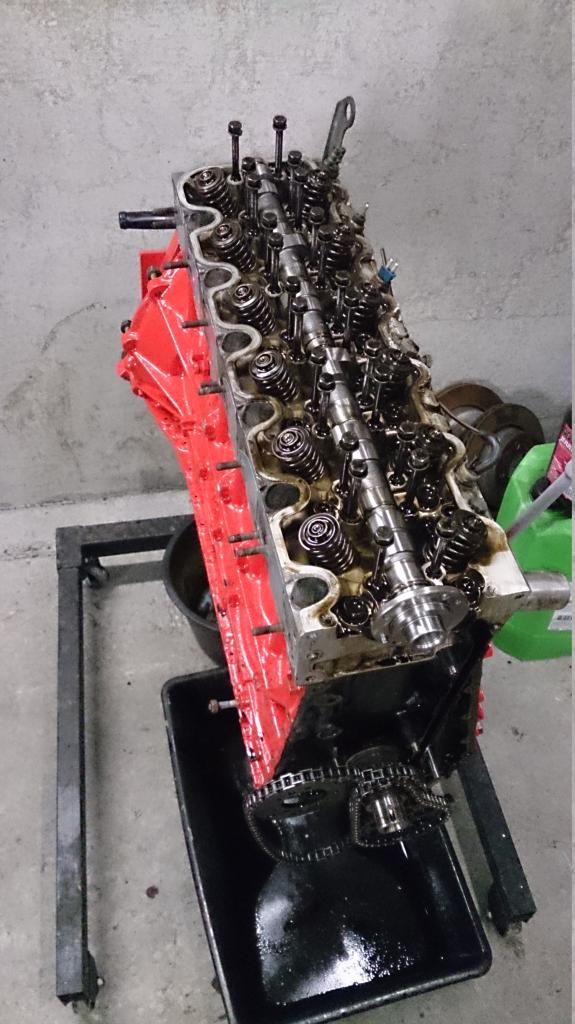

Gotta love that typical 24v straight-six howl

Gotta love that typical 24v straight-six howl

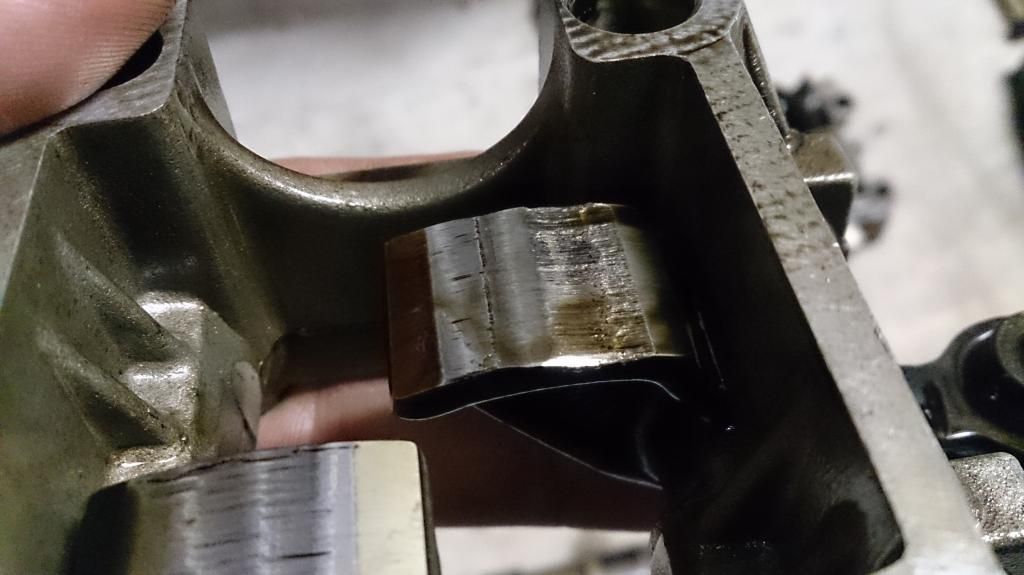

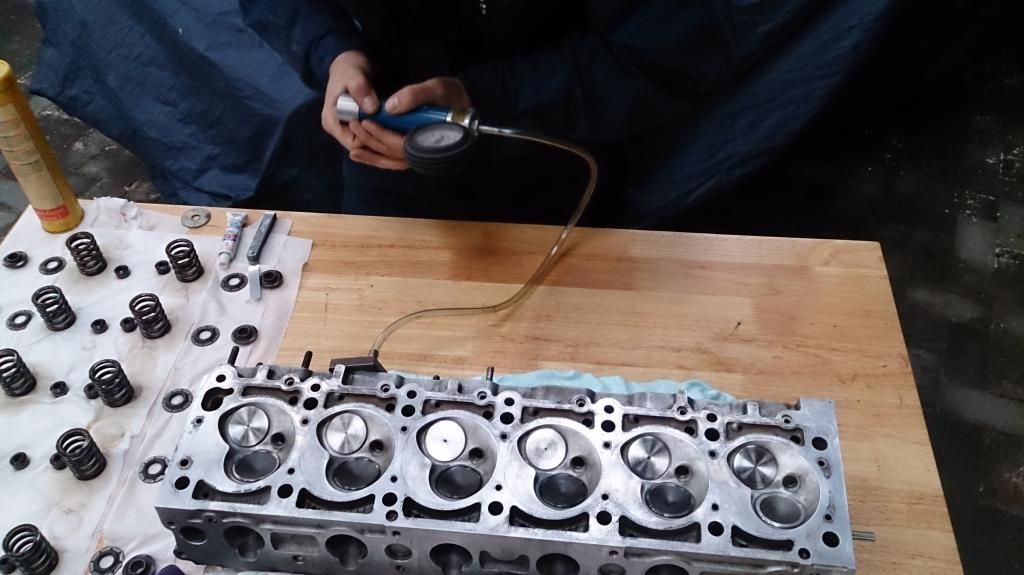

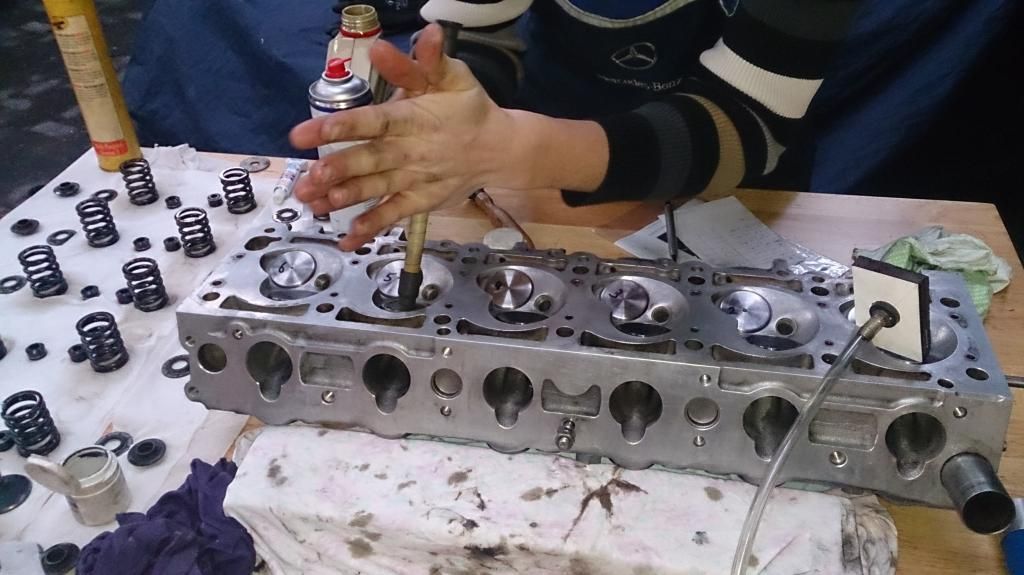

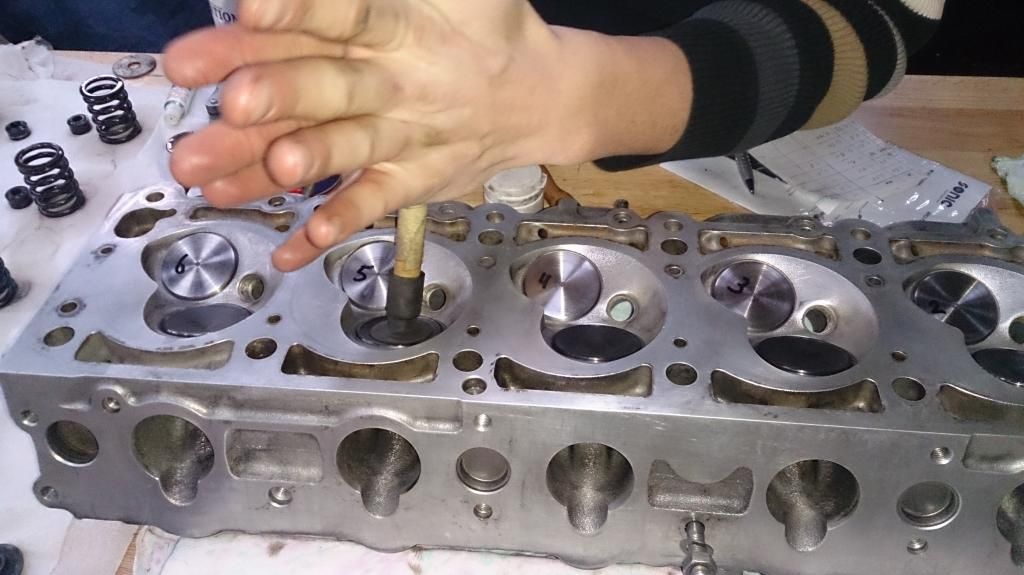

new valve, gaskets, clutch pressure plate and other small bits ´n pieces...

new valve, gaskets, clutch pressure plate and other small bits ´n pieces...

)

)

Comment