G'day blokes,

I thought I'd start a thread to keep track of my progress. Late last year I bought a 2006 B7 A4 Avant. This is my first Audi in a long line of project cars and it had to be a wagon! I'll be putting a lot of time into getting it spot on.

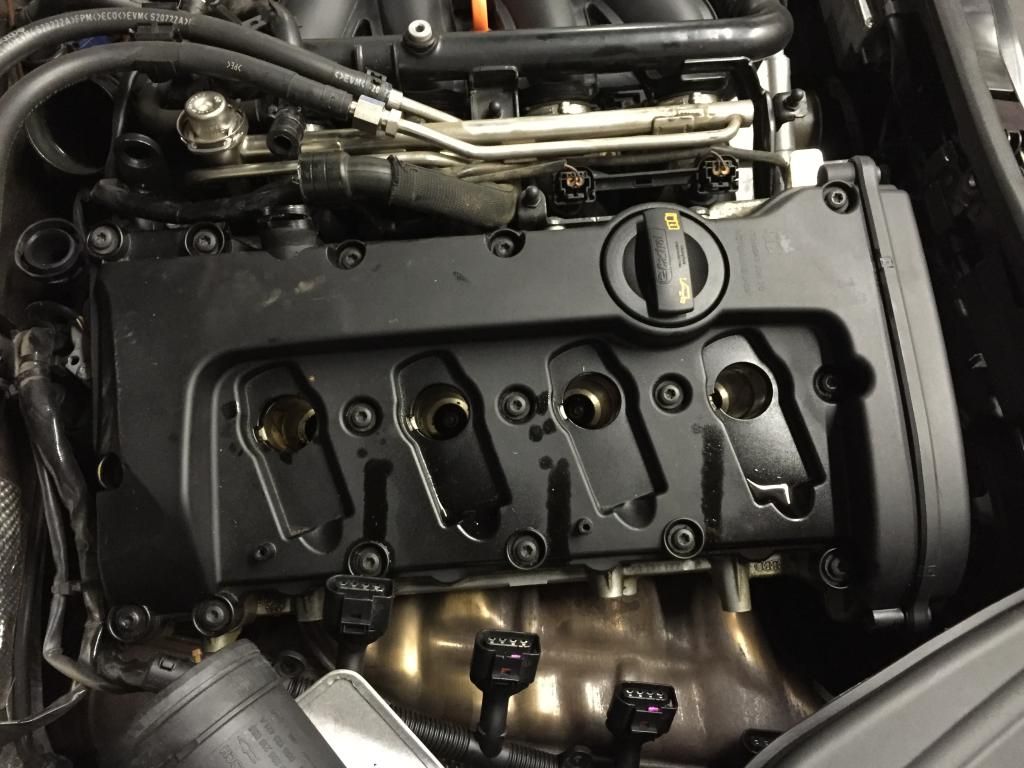

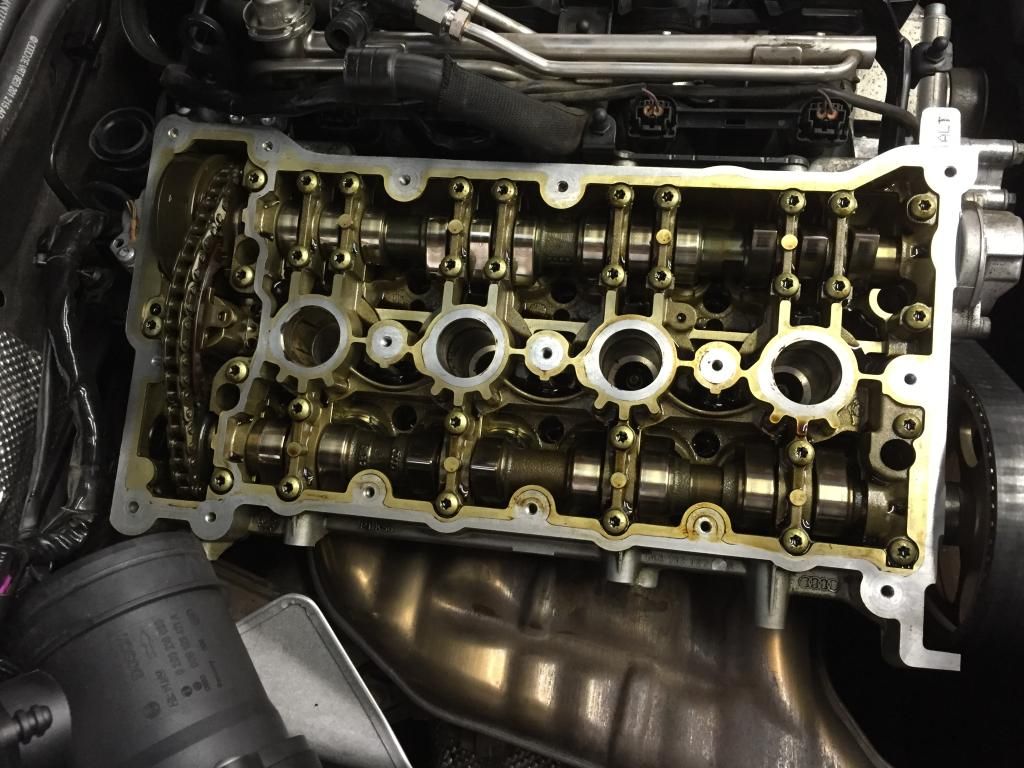

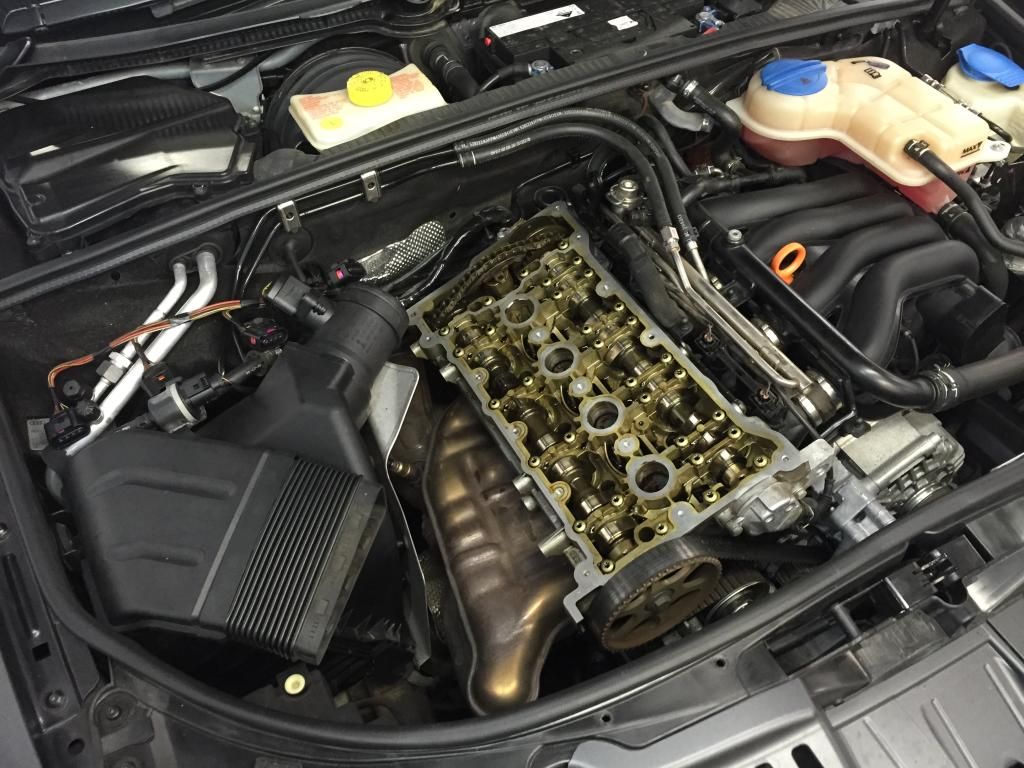

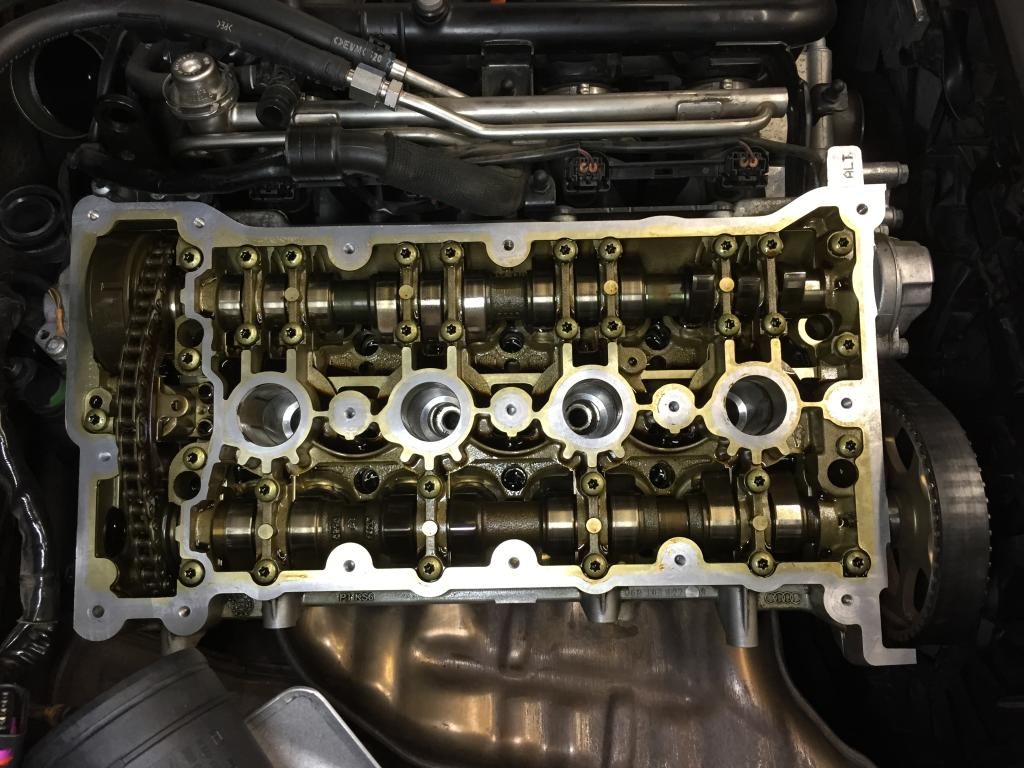

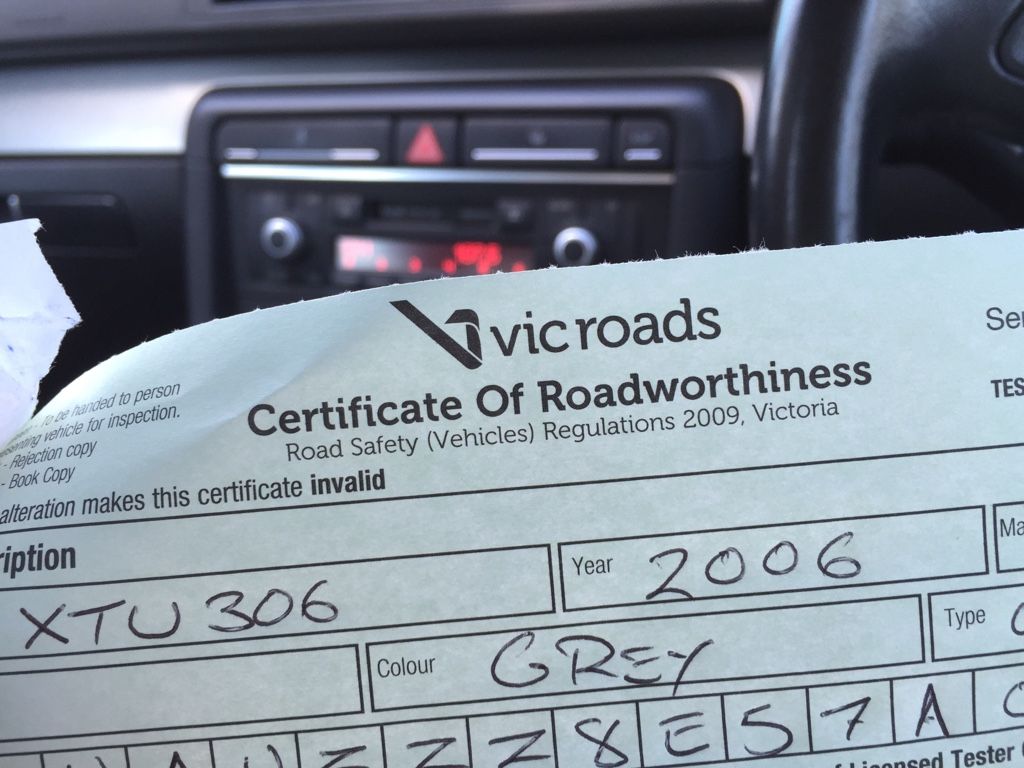

The car is a Lava Grey 2.0i 20V model. I don't think you had any A4s sold with the ALT motor in North America? It's not a powerhouse performer, but it's perfect for my needs. As a daily driver slow is fine.

Back in 2005 Audi released a 'Sport Edition' of the A4 in Australia (maybe elsewhere too?) separate from the S-Line. It was limited to 200 units and all of them came with unique bumpers, side skirts and roof spoiler, plus a Nokia 8800 mobile phone and built in Bluetooth. Classic marketing gimmick. My car is too late to be one of those 200, but has the same body add-ons.

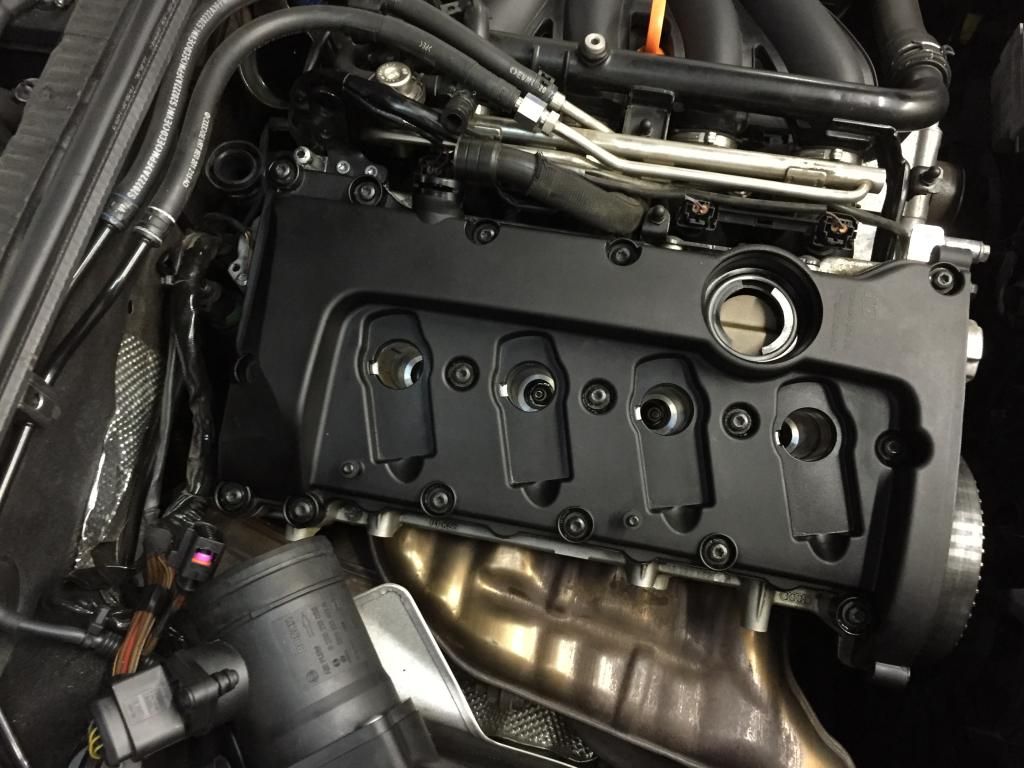

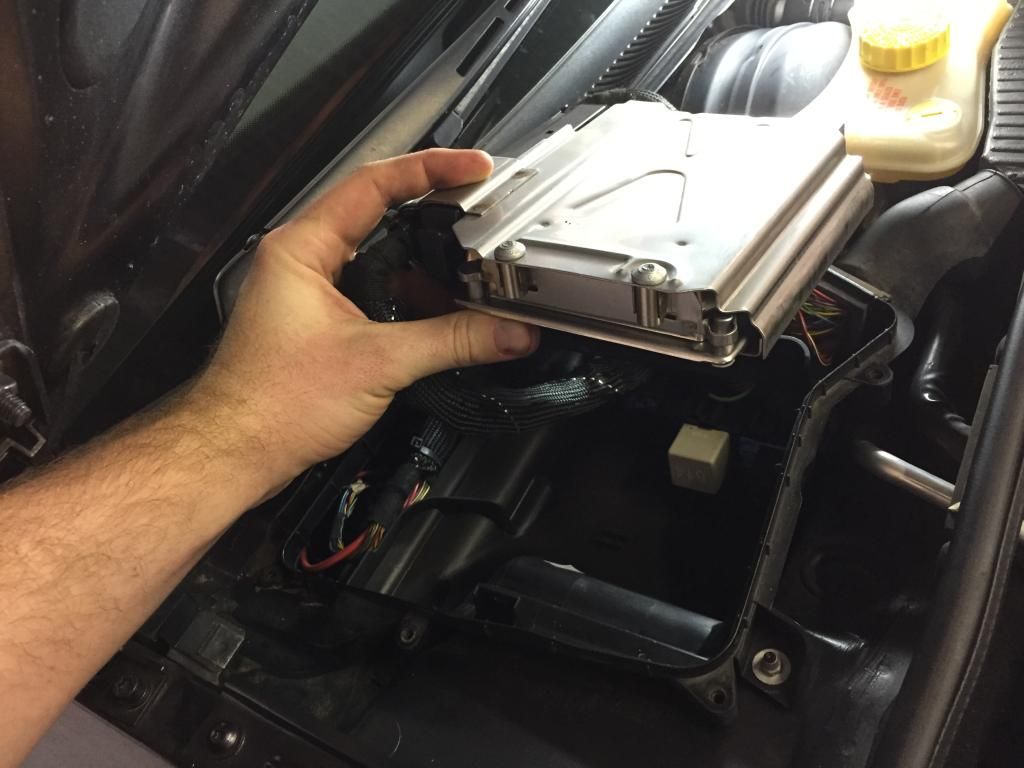

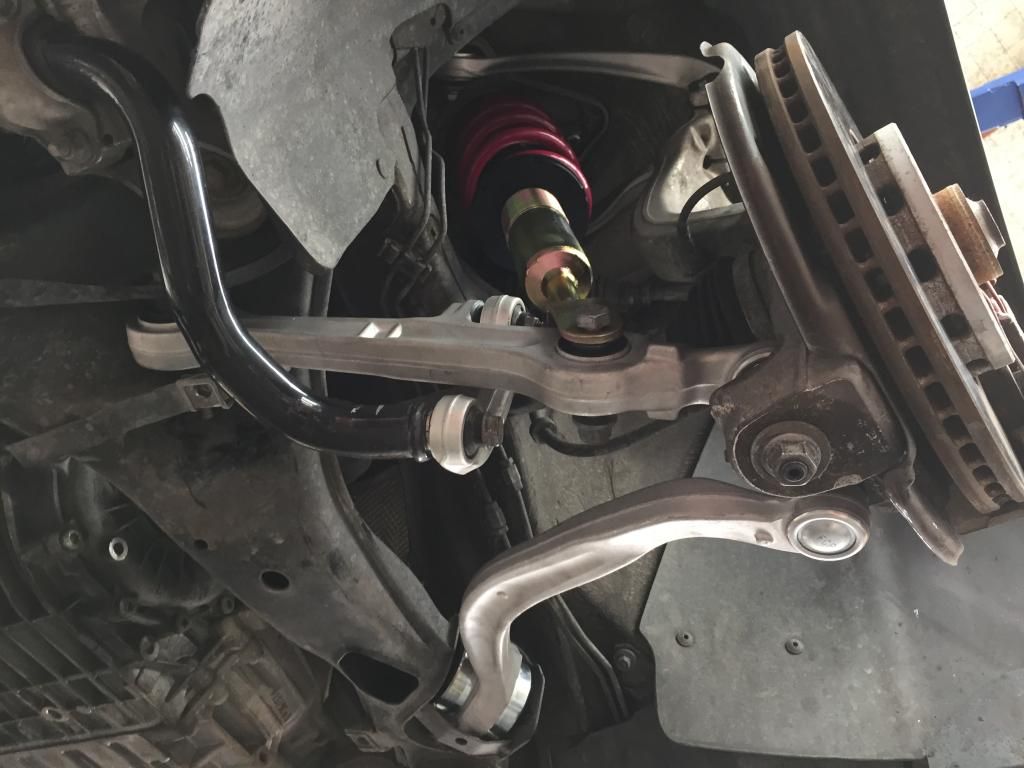

The plan is to get the car mint inside and out. Coilovers and wheels will follow and a few more ideas I've got in my head.

Here are some weak pics from before I bought it. I'll snap some better ones soon.

And here's some inspiration. Obviously this is a B6, but as far as styling goes I reckon it's perfection.

More to come.

I thought I'd start a thread to keep track of my progress. Late last year I bought a 2006 B7 A4 Avant. This is my first Audi in a long line of project cars and it had to be a wagon! I'll be putting a lot of time into getting it spot on.

The car is a Lava Grey 2.0i 20V model. I don't think you had any A4s sold with the ALT motor in North America? It's not a powerhouse performer, but it's perfect for my needs. As a daily driver slow is fine.

Back in 2005 Audi released a 'Sport Edition' of the A4 in Australia (maybe elsewhere too?) separate from the S-Line. It was limited to 200 units and all of them came with unique bumpers, side skirts and roof spoiler, plus a Nokia 8800 mobile phone and built in Bluetooth. Classic marketing gimmick. My car is too late to be one of those 200, but has the same body add-ons.

The plan is to get the car mint inside and out. Coilovers and wheels will follow and a few more ideas I've got in my head.

Here are some weak pics from before I bought it. I'll snap some better ones soon.

And here's some inspiration. Obviously this is a B6, but as far as styling goes I reckon it's perfection.

More to come.

Comment