Well we're back at it with another old Chevy build. The Commonwealth shop truck (58 Apache) as well as my buddies 1966 Chevy c10 have been put on a slight hold while we take care of this customer build.

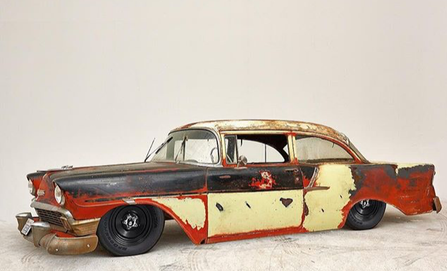

Matt came to us with an idea to build his 1956 Chevy Belair 2 door which he found on craigslist in San Diego. The car was being daily driven by its previous owner and the lack of rust and cool patina, we knew it would be perfect for our build. After some waiting and cash exchanging hands the car landed at our shop in London, Ontario on October 29th.

Being that it is an all original 56 210 Belair with the 235ci inline 6 we knew this car would need some upgrading.

The plan:

Engine: 495hp LS3 crate motor from GM performance

Trans: Tremec T56 6 speed

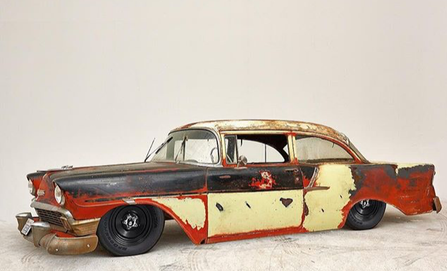

Rear end: Custom Dutchman Motorsports Ford 9"

Brakes: 4 piston Wilwood disc brakes all around

Front suspension: Custom built front frame section, crossmember, control arms and slam specialties ss-6 bags

Rear suspension: Custom notched frame, 4 link and slam specialties ss-7 bags

Air management: Airlift 3H managment, dual Viair compressors and Specialty suspension seamless tanks

Steering: upgraded to power rack and pinion

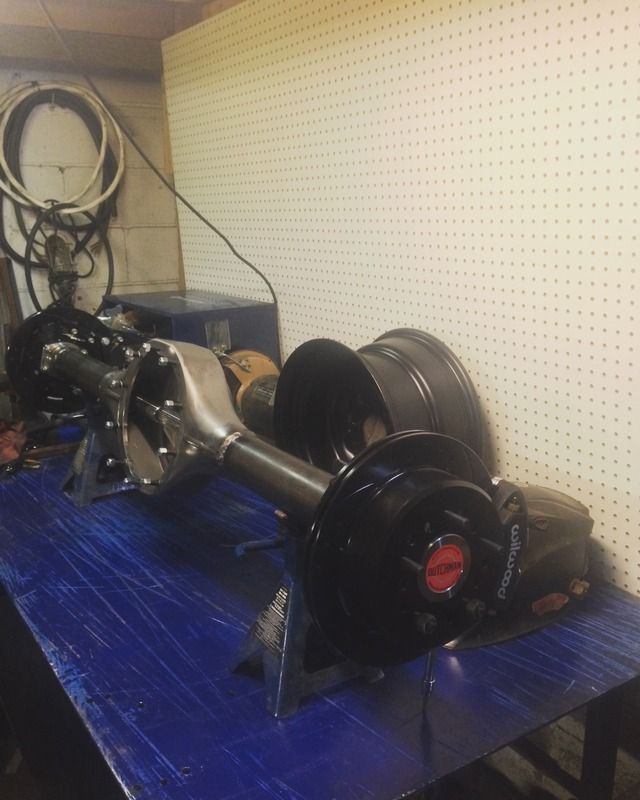

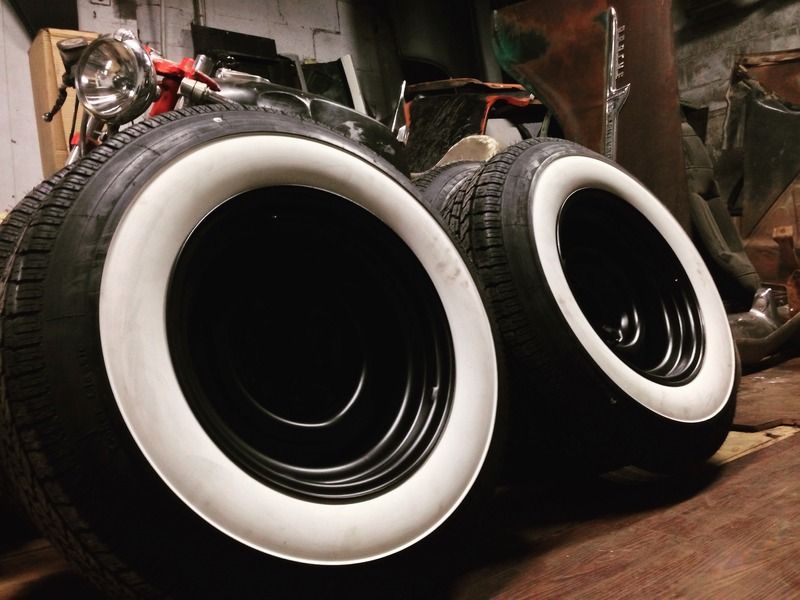

The plan is to have the car look fairly stock on the outside and completely new where it counts. Stock vintage steelies with hub caps and white walls will make it appear 50's on the outside all while laying frame with 4 times the stock power.

We will be updating frequently since we want to have this car on the road by June 2017. Check out our instagram @commonwealth_mf and the cars IG @56chevy150 for even more frequent updates.

Onto some pics

Matt pulled the car into his studio to get some glamour shots before it arrived at the shop

Photoshop of the end goal

The day it showed up at the shop

2 hours later

First bit or parts in from TMR Customs. Rod ends and tube bushings for the 4-link. This is a small fraction of the parts we have waiting.

And just had to test out the capabilities of the stock 125hp power plant

Matt came to us with an idea to build his 1956 Chevy Belair 2 door which he found on craigslist in San Diego. The car was being daily driven by its previous owner and the lack of rust and cool patina, we knew it would be perfect for our build. After some waiting and cash exchanging hands the car landed at our shop in London, Ontario on October 29th.

Being that it is an all original 56 210 Belair with the 235ci inline 6 we knew this car would need some upgrading.

The plan:

Engine: 495hp LS3 crate motor from GM performance

Trans: Tremec T56 6 speed

Rear end: Custom Dutchman Motorsports Ford 9"

Brakes: 4 piston Wilwood disc brakes all around

Front suspension: Custom built front frame section, crossmember, control arms and slam specialties ss-6 bags

Rear suspension: Custom notched frame, 4 link and slam specialties ss-7 bags

Air management: Airlift 3H managment, dual Viair compressors and Specialty suspension seamless tanks

Steering: upgraded to power rack and pinion

The plan is to have the car look fairly stock on the outside and completely new where it counts. Stock vintage steelies with hub caps and white walls will make it appear 50's on the outside all while laying frame with 4 times the stock power.

We will be updating frequently since we want to have this car on the road by June 2017. Check out our instagram @commonwealth_mf and the cars IG @56chevy150 for even more frequent updates.

Onto some pics

Matt pulled the car into his studio to get some glamour shots before it arrived at the shop

Photoshop of the end goal

The day it showed up at the shop

2 hours later

First bit or parts in from TMR Customs. Rod ends and tube bushings for the 4-link. This is a small fraction of the parts we have waiting.

And just had to test out the capabilities of the stock 125hp power plant

Comment