It's been a while  But I have had a lot of school work so only small progress i made when i have time for that!

But I have had a lot of school work so only small progress i made when i have time for that!

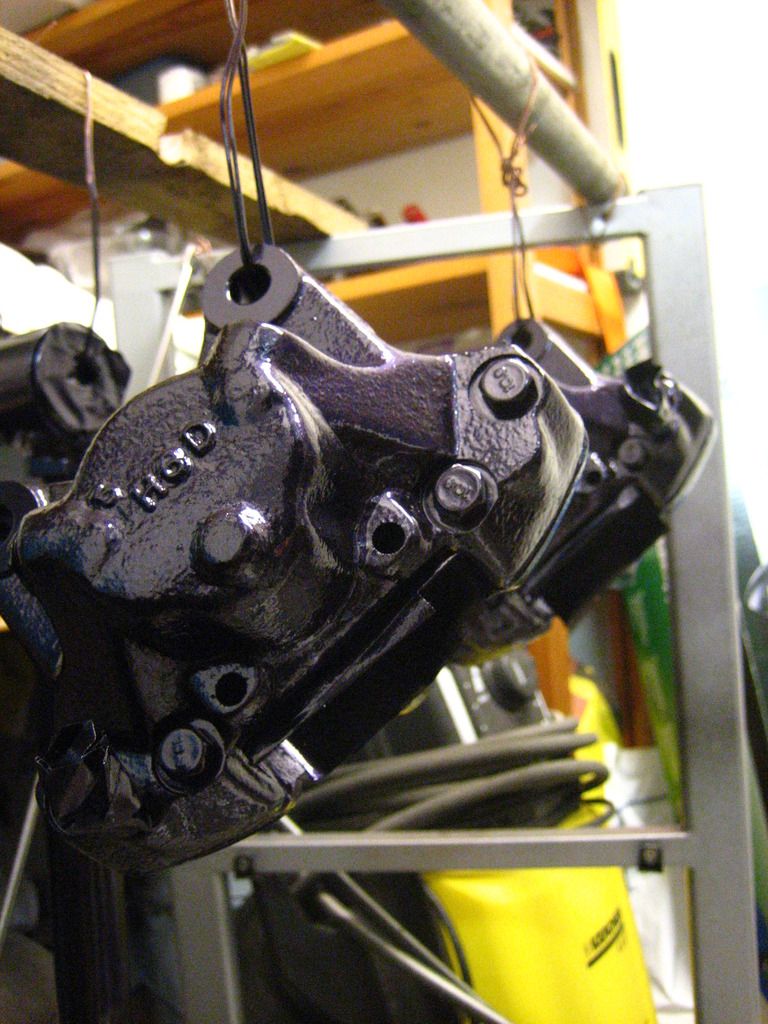

At the moment the i have disassembled all of the suspension rear axle and support arms those are waiting for sandblasting powdercoating and new bushes. I also found some rot so some welding has to be done Bought mig welding equipment so i have to learn on that a bit! Let see how bad i am at welding! Also planning on doing stainless steel exhaust while it's easy acessible!

Bought mig welding equipment so i have to learn on that a bit! Let see how bad i am at welding! Also planning on doing stainless steel exhaust while it's easy acessible!

Some pics

And yeah I also bought a donor car for the engine swap ! A 1993 e34 525 with m50b25tu and 5-speed zf. Im going to use it as my daily during the winter and strip it a part in the summer as the volvo is driveable again

! A 1993 e34 525 with m50b25tu and 5-speed zf. Im going to use it as my daily during the winter and strip it a part in the summer as the volvo is driveable again  And the plans for the engine are a bit open at the moment. Only thing i know for sure that it's not going to be naturally aspirated. Im not sure about the internals yet. New bearings, piston rings, arp and hoon it or go full crazy and put some forged internals.

And the plans for the engine are a bit open at the moment. Only thing i know for sure that it's not going to be naturally aspirated. Im not sure about the internals yet. New bearings, piston rings, arp and hoon it or go full crazy and put some forged internals.

I was also suprised how nice the car is! Really quite great interior( black leather sport seats) and the engine is great! I will post some more during the christmas holidays as i plan to do some work on the car!

But I have had a lot of school work so only small progress i made when i have time for that!

But I have had a lot of school work so only small progress i made when i have time for that! At the moment the i have disassembled all of the suspension rear axle and support arms those are waiting for sandblasting powdercoating and new bushes. I also found some rot so some welding has to be done

Bought mig welding equipment so i have to learn on that a bit! Let see how bad i am at welding! Also planning on doing stainless steel exhaust while it's easy acessible!

Bought mig welding equipment so i have to learn on that a bit! Let see how bad i am at welding! Also planning on doing stainless steel exhaust while it's easy acessible!Some pics

And yeah I also bought a donor car for the engine swap

! A 1993 e34 525 with m50b25tu and 5-speed zf. Im going to use it as my daily during the winter and strip it a part in the summer as the volvo is driveable again

! A 1993 e34 525 with m50b25tu and 5-speed zf. Im going to use it as my daily during the winter and strip it a part in the summer as the volvo is driveable again  And the plans for the engine are a bit open at the moment. Only thing i know for sure that it's not going to be naturally aspirated. Im not sure about the internals yet. New bearings, piston rings, arp and hoon it or go full crazy and put some forged internals.

And the plans for the engine are a bit open at the moment. Only thing i know for sure that it's not going to be naturally aspirated. Im not sure about the internals yet. New bearings, piston rings, arp and hoon it or go full crazy and put some forged internals.

I was also suprised how nice the car is! Really quite great interior( black leather sport seats) and the engine is great! I will post some more during the christmas holidays as i plan to do some work on the car!

well next day the weather wasn't that bad so i got to continue with the rear axle.

well next day the weather wasn't that bad so i got to continue with the rear axle.

Comment