Yes! These chassis are so cool. Glad to see you kept at it all this time.

Announcement

Collapse

No announcement yet.

Champagne Realities RX7

Collapse

X

-

A straight, cut to length hose generally doesn't have enough play to accommodate engine twist/chassis flex etc, having the curved hose does.Originally posted by Hayce View PostThat is so good!

I'm about to redo the cooling on my 2J, why does pretty much no one reroute the top hose to the top left of the radiator so it's straight?Instagram: @Eurow

Comment

-

Mmm, really? Find that hard to believe.. I mean most 2J's have a massive turbo close to the strut tower, that would hit if twist was that bad. I figured it was more due to the fan/cowl being in the way.Originally posted by MikeyRa View PostA straight, cut to length hose generally doesn't have enough play to accommodate engine twist/chassis flex etc, having the curved hose does.

RB: http://orig15.deviantart.net/4110/f/...ay-d5lcmuo.jpg

2J with cowl: https://encrypted-tbn0.gstatic.com/i...DAtB6W1vsbJ97v

Maybe you're right: https://i.pinimg.com/originals/07/23...7b9445b430.jpg

Work gone into that, surely would have straightened if they wanted.

Comment

-

.Originally posted by Hayce View PostMmm, really? Find that hard to believe.. I mean most 2J's have a massive turbo close to the strut tower, that would hit if twist was that bad. I figured it was more due to the fan/cowl being in the way.

RB: http://orig15.deviantart.net/4110/f/...ay-d5lcmuo.jpg

2J with cowl: https://encrypted-tbn0.gstatic.com/i...DAtB6W1vsbJ97v

Maybe you're right: https://i.pinimg.com/originals/07/23...7b9445b430.jpg

Work gone into that, surely would have straightened if they wanted.

Untitled.jpg

The hose being "S" shaped or having a curve in it will also allow it to "compress" forwards and backwards without pulling on the ends or kinking. The "S" lets the hose rotate without twisting itInstagram: @Eurow

Comment

-

Got my tires mounted today and the ride height set. Was able to put about 45 miles on the car since i got plates this week as well. So far so good. Biggest issue i am having is an oil drip from the oil cooler thermostat bolt but have an order from mazdatrix coming tomorrow which includes new front wheel bearings and a new crush washer for the oil cooler. Also have some KAAZ LSD fluid that should be here tomorrow to hopefully help quiet down my diff. I am suspecting the kid who owned it before didnt use KAAZ fluid in it which causes clunking on slow turns. Heres some pics from a photoshoot i took while on a beer run :cheers:

Tires are 225/40/R18 and 265/40/R18

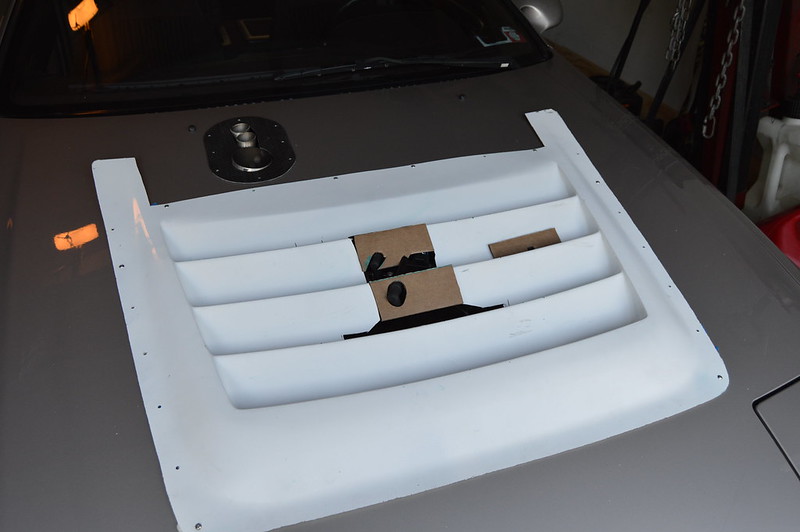

Also got my hood vent in. Not very happy with the quality on this, going to need some work before its acceptable. I will be trimming the rear a lot and probably mounting it lower than it is currently.

@dano_reyno

@dano_reyno

Comment

-

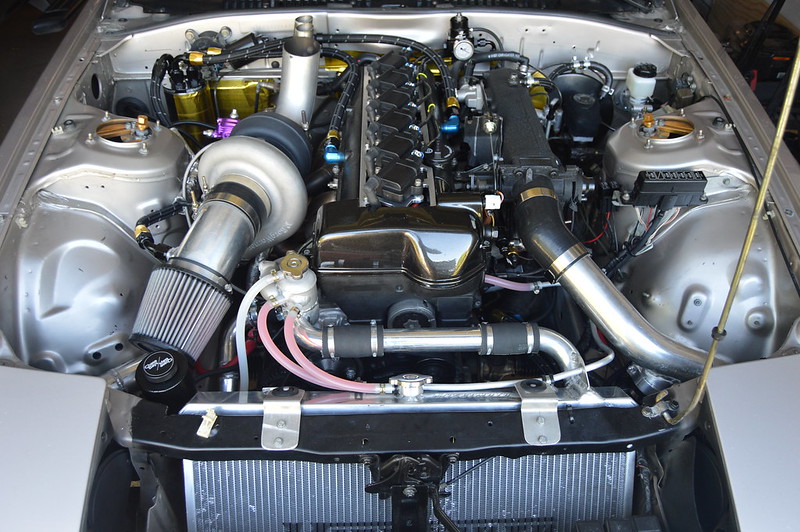

Currently have about 200 miles on the car but started running into some fuel pressure issues. Have a bunch of stuff to fix that then we can get back to street tuning the car. The few pulls i did get in felt pretty damn good on the current rough tune. Have a few things that i will be refining after all the bugs are worked out which include explorer 8.8 kit to bring the final drive down (4.11s on the street suck lol, 65MPH cruise puts me at about 3100RPM), full exhaust out the back of the car, and some heat management to bring down in cabin temperatures.

https://youtu.be/_XAWOe1rMIc

Started getting some nice colors on the manifold

hood cut for the vent

Mounted in final position using rivnuts

Vent openings trimmed roughly and rear cut straight

Templates cut for a better fit. Will be grafting fiberglass pieces in then final prep/ sanding on whole vent before paint.

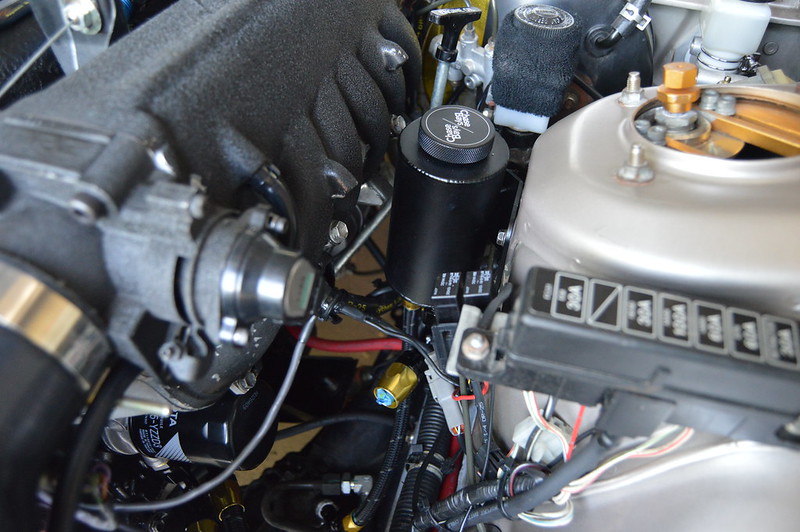

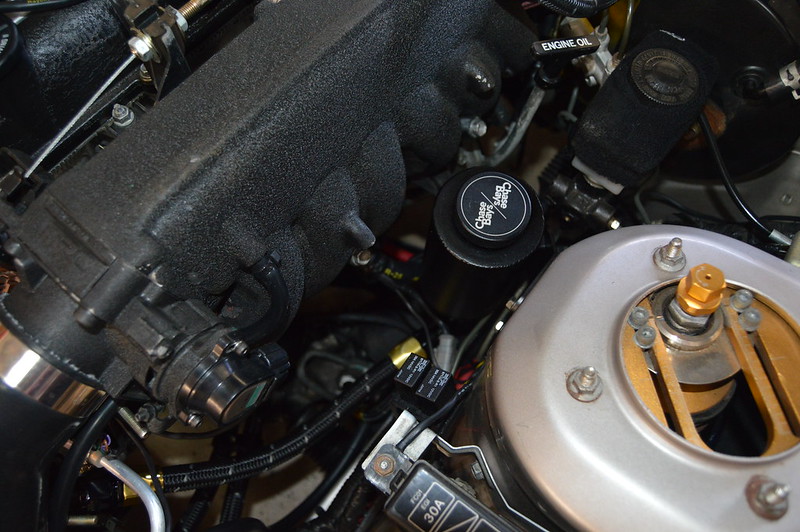

Chase bays coolant overflow installed

Need to get started on some carbon ducting for the radiator next. Also working with chase bays on a FC-2JZ power steering kit and having some trouble finding the correct fittings so still researching that and exploring options.@dano_reyno

Comment

-

leather jackets are the perfect item to wear for this time period but let me tell you a little secret.They are perfect year round.don't be afraid to invest in the leather like jacket because i promise you'll get your money's worth.

Comment

-

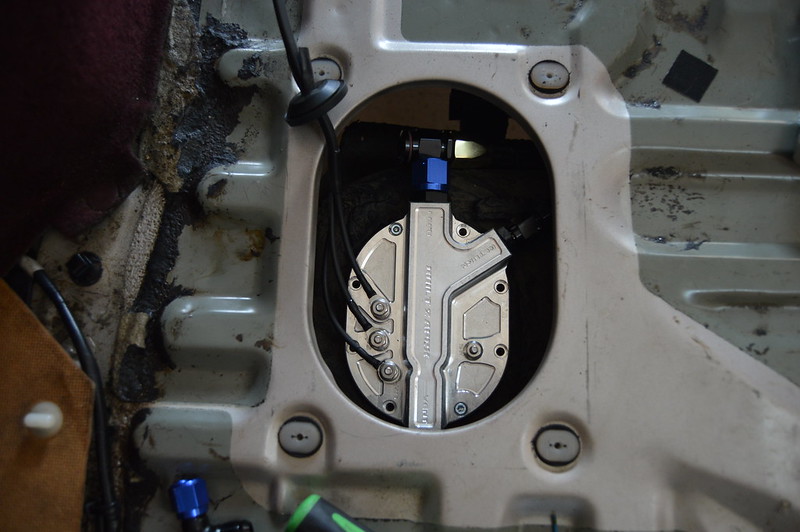

is this forum still alive? Update on my fuel pressure issues, pulled the old fuel filter and found some junk on there but nothing serious. At this point i was waiting on a dual pump hanger i ordered.

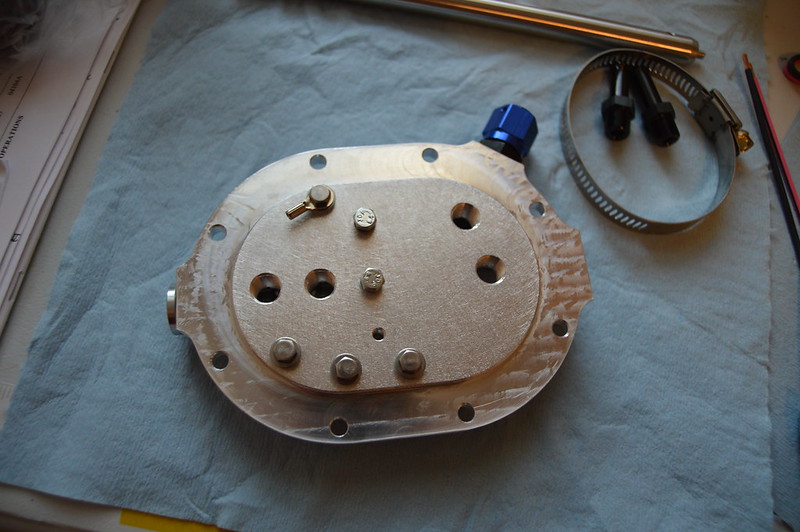

I have mounted the new Radium fuel filter above the rear diff and it appears that my current fuel lines will work.

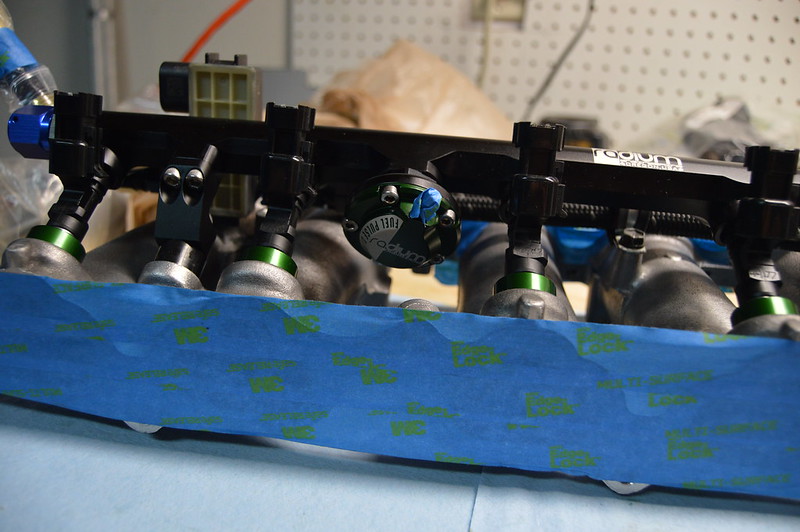

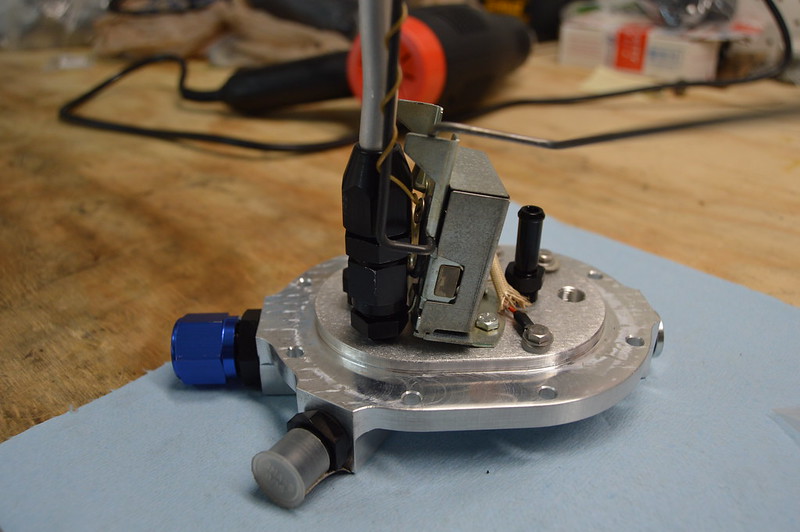

Pulled the intake off to install this fuel pulse damper and also found/fixed an oil leak from the CMP sensor. Intake gasket was questionable so i installed a sikky thermalnator phenolic intake gasket which claims to reduce IATs by 25-35*.

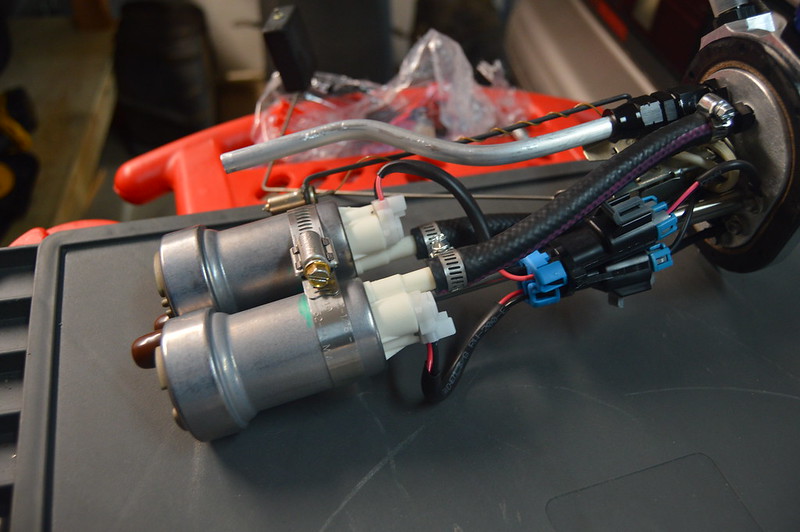

So i feel like such a fool, i finished plumbing up my fuel filter and decided to just pull the pump out to see if there is anything obvious and look what i find... this would explain a lot about how this all began and i am really surprised that this thing still built 40+ PSI of fuel pressure under light load. i think the only thing saving it at all was the stiffness and length of the fuel line prevented it from completely popping off. that silver fitting was a spare that came with my FPR and i almost bought another one because there was no barb on it but figured it would work.. O well, at least my fuel system will be bullet proof and be able to support E85 no problem now.

Do you see it??

how about now?

Fuel filter mounted and lines hooked up. This is a tight fit but it clears the tie rods under full compression.

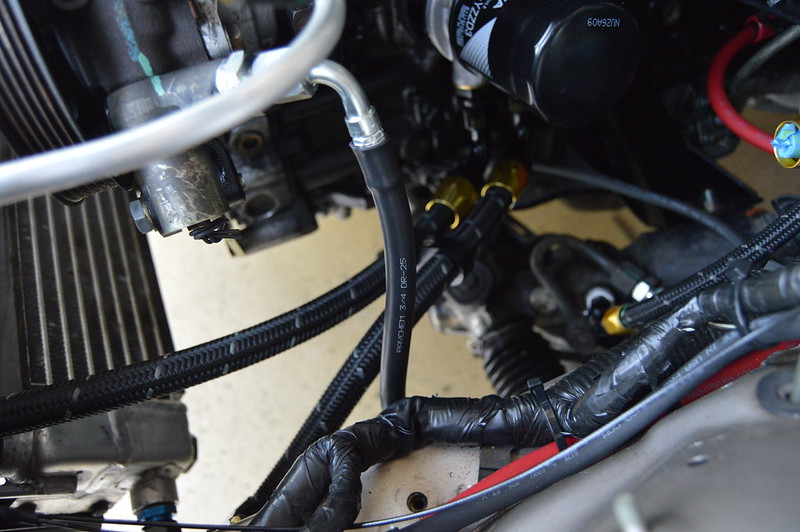

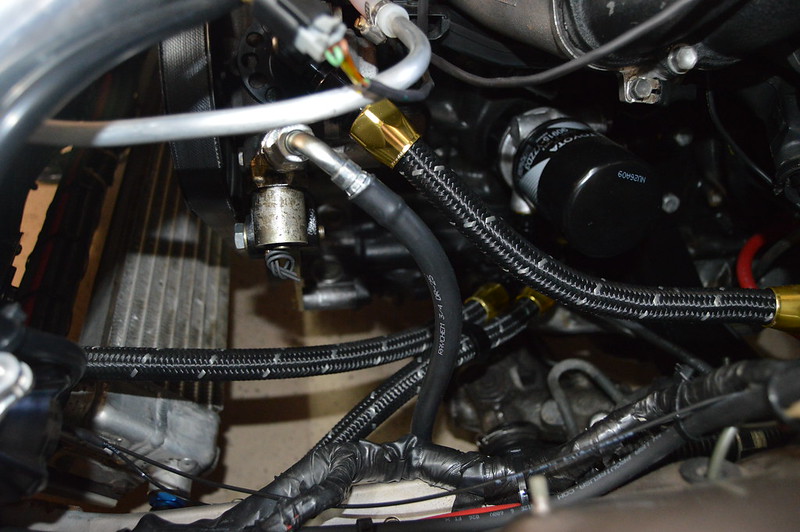

And started plumbing up the power steering system, just need to pick up an AN adapter for the pump suction line and a new O ring for the HP banjo line. Looking for one if anyone has any laying around!!

@dano_reyno

@dano_reyno

Comment

-

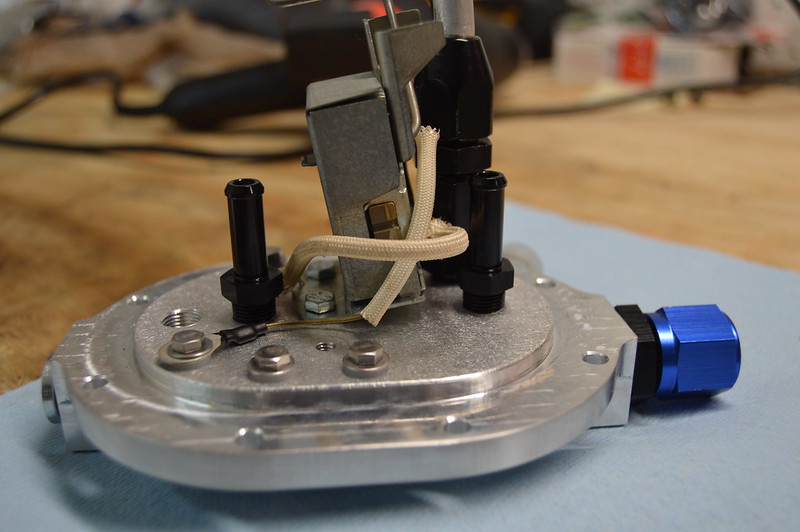

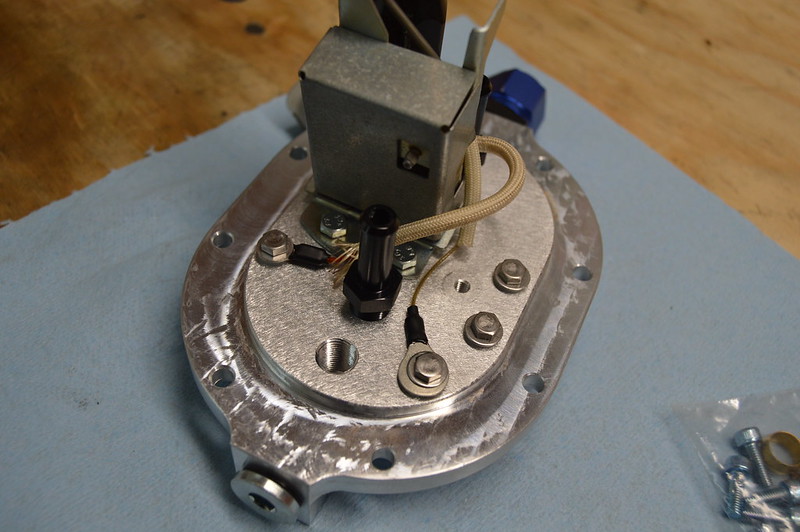

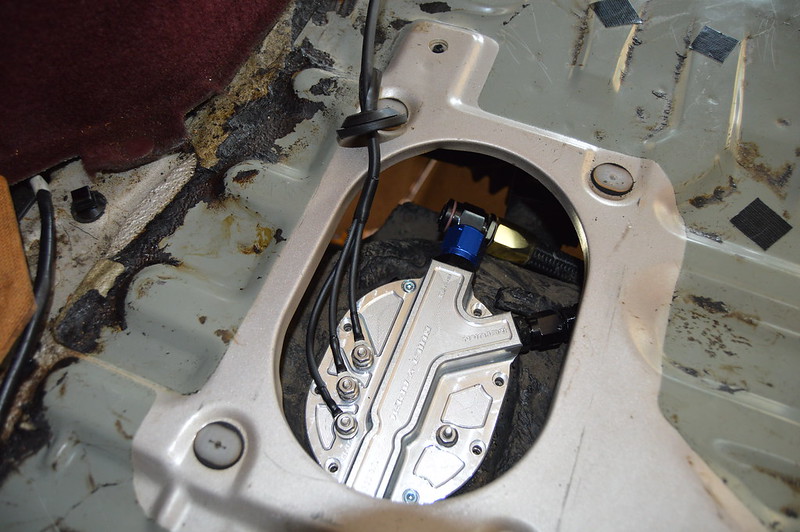

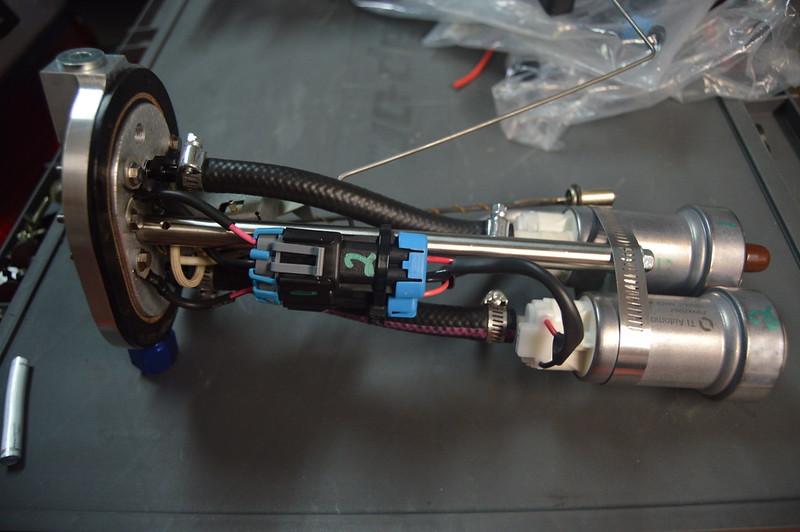

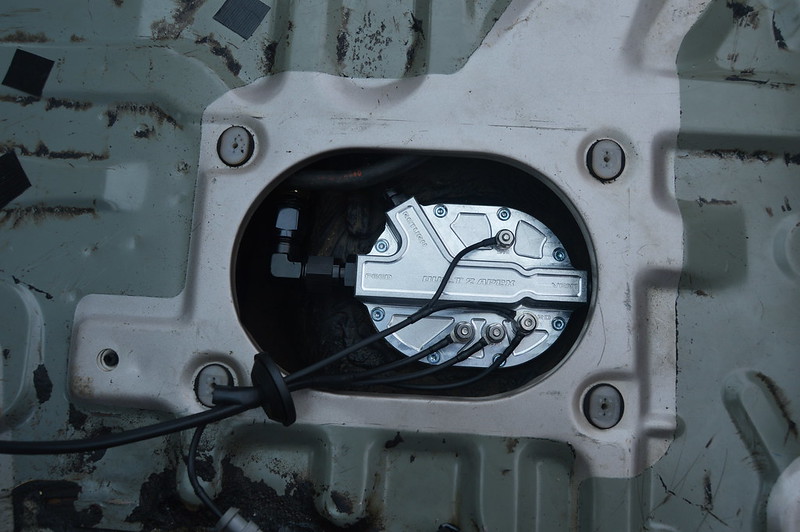

Got some stuff figured out to get this fuel system finished up and wired up the topside. I wanted to run a hardline return which required a bulkier fitting combo. This required some bending on the top tab to offset the resistor box, and then some bending on the float and ground rod to bring them back perpendicular with the tank floor.

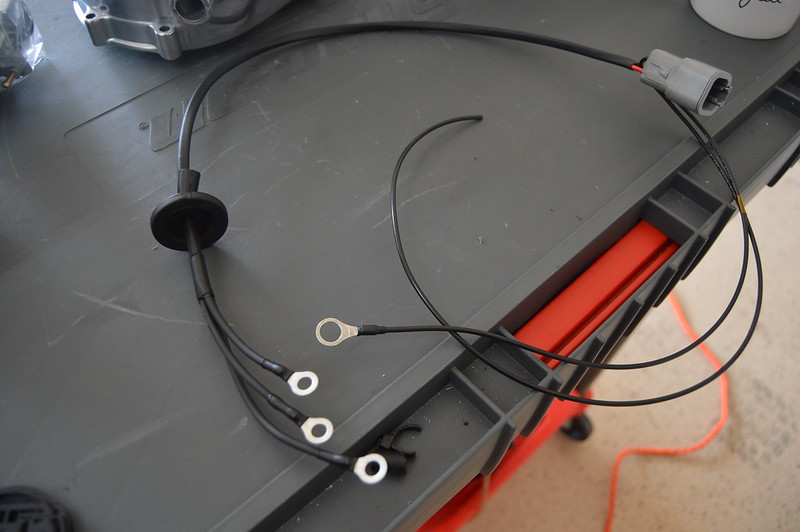

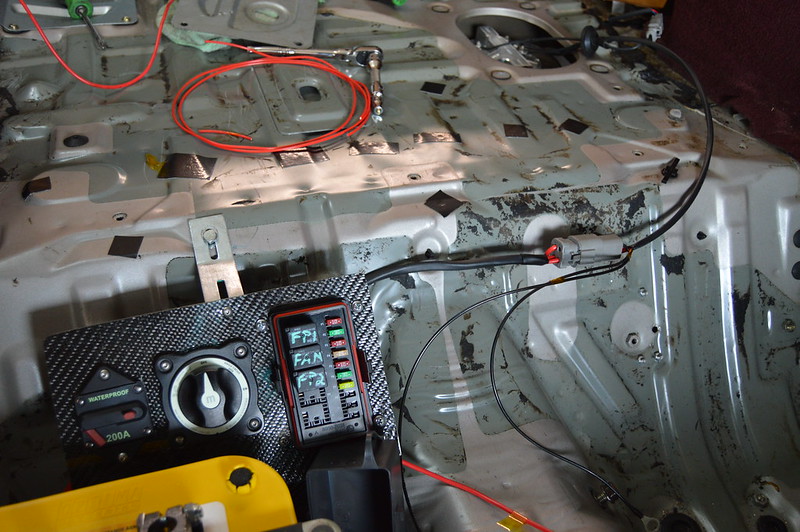

Power/ground pump harness which includes a circuit for the cooling fan output. this is all 12GA tefzel

I wanted to be able to remove the whole pump harness yet and run it through the original grommet so i wired up the tank level sender on a separate harness also running through the grommet with a 2 pin Deutsch connector.

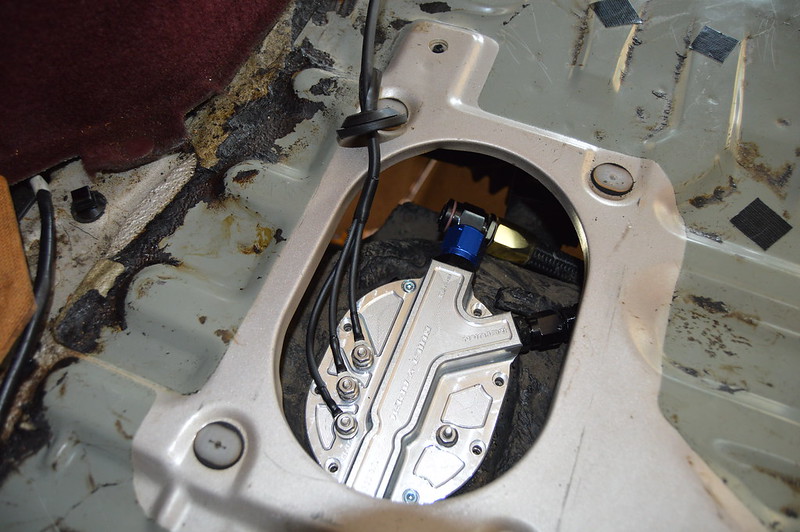

Topside is all wired and ready to go, just waiting on the spacer to mount the pumps. I ran into an issue with the feed line having a tight bend when hooked up so i ordered a female to male 45* and 90* fitting to come off the tophat. I will try to run the 45* to increase flow a little, but we will see what fits better. This was easier than dropping the diff and running a new line (my lines run above the diff and through the OEM bracket). this pic shows the angle of the feed compared to the straight -8 fitting.

@dano_reyno

@dano_reyno

Comment

-

Quick update on this thing, i have driven it after replacing the pump and my low fuel pressure issues are resolved of course. However, i am having issues with my aeromotive FPR (which has been having issues from the start) and will be replacing it for a fuellab unit. First issue is with the dual pumps running at idle and off boost, there is too much flow for the aeromotive to handle and it will not go below 50PSI. I know the return port on these is very small and this is an older model, but the regulator also does not pull 1:1 boost reference, nor does it hold pressure once the key is off. I have been reading a lot of horror stories with these units and their quality so i will just replace it and stage my pumps to keep fuel temps down. Other than that, i did beat on it for a bit one day and it is getting pretty quick. I will upload some pulls to youtube later.

Need to wrap up power steering, get an alignment, and replace this FPR then start enjoying the car more in the cooler weather coming to TX!@dano_reyno

Comment

-

So i custom ordered a fuellab FPR with the large seat and out of the box my fuel pressure was 35 PSI with both pumps running. Much better compared to the aeromotive which could not drop below 50PSI with the screw turned all the way out. I also pulled the aeromotive apart and the seat looked to be updated from the pictures i found and it was cut correctly however still did not increase FP 1:1 with boost. Fuel pressure is now rock steady and barely fluctuates 1PSI throughout the powerband and raises 1:1 also. Very happy with the fuel lab setup coupled with the radium pulse damper.

With that solved i was able to do some WOT pulls but found i was hitting 19PSI running 15PSI wastegate springs (boost controller not on yet). Swapped down to some 10PSI springs and now im at 13.5PSI which is right at the 14PSI target for my current tune revision. Datalogs sent away and waiting on another revision now. Also got power steering hooked up finally and the car is much more enjoyable to drive. This setup is the stock VVTI PS pump with the solenoid disconnected, excessive manufacturing HP line, -6 conversion fitting and -6 return line, and -10 suction line using a chase bays baffled reservoir. The steering feels good and is not too light at speed yet manageable during low speed turning. From what i remember it is slightly less assist than the OEM steering setup.

@dano_reyno

@dano_reyno

Comment

Comment