Appreciate all the positive comments guys! Great to see i'm helping others to sink more time into their builds!

Announcement

Collapse

No announcement yet.

Another BMW E28 - This Time From Australia

Collapse

X

-

-

I've been slowly getting through this conversion.

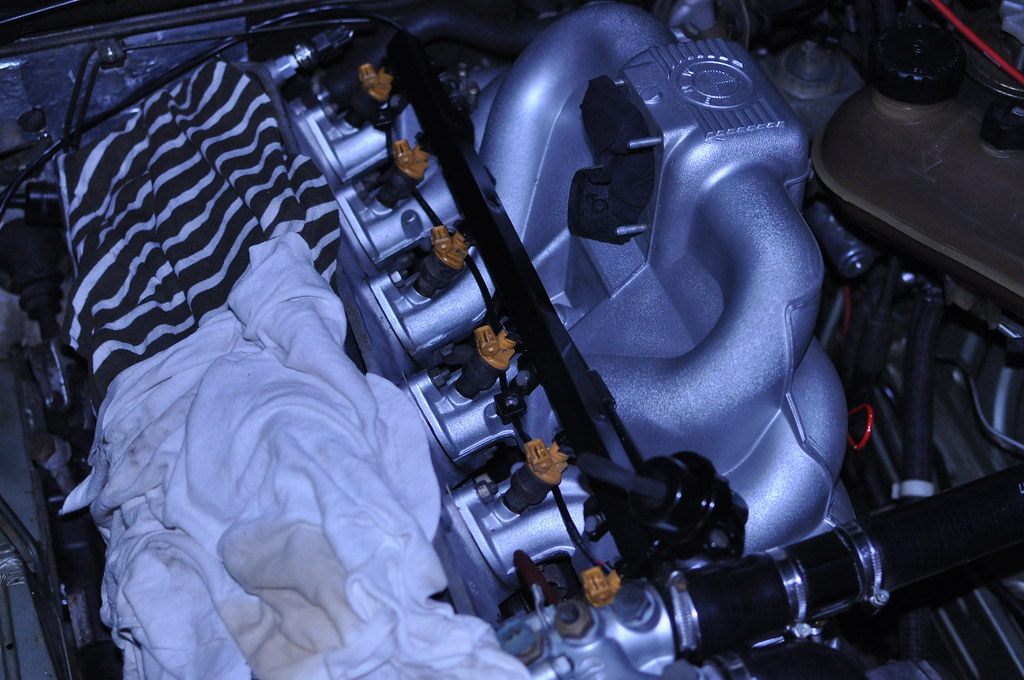

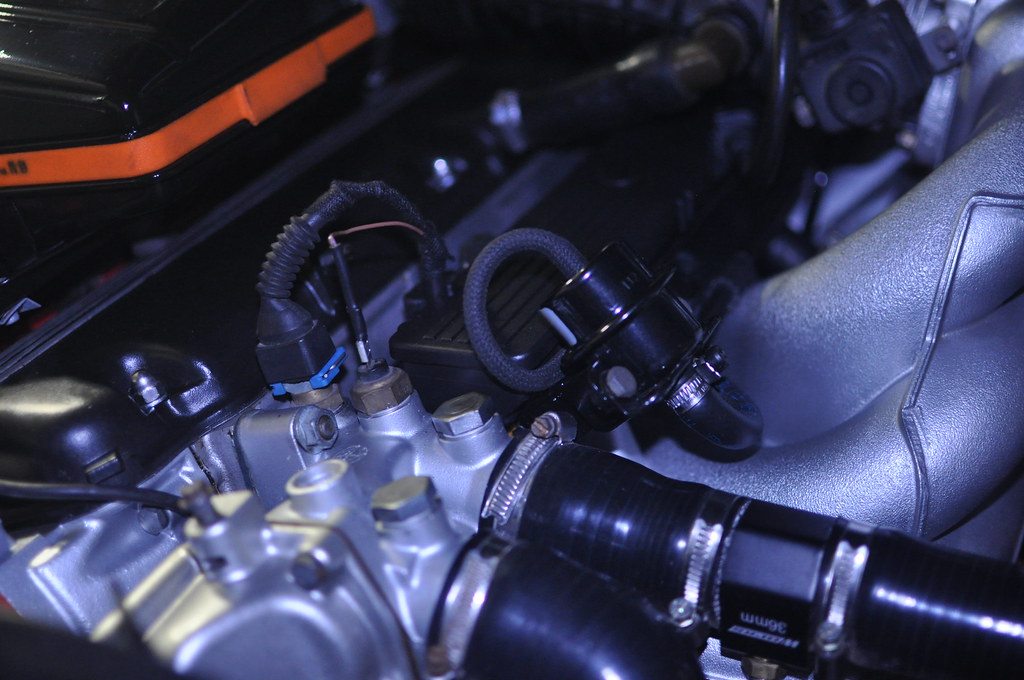

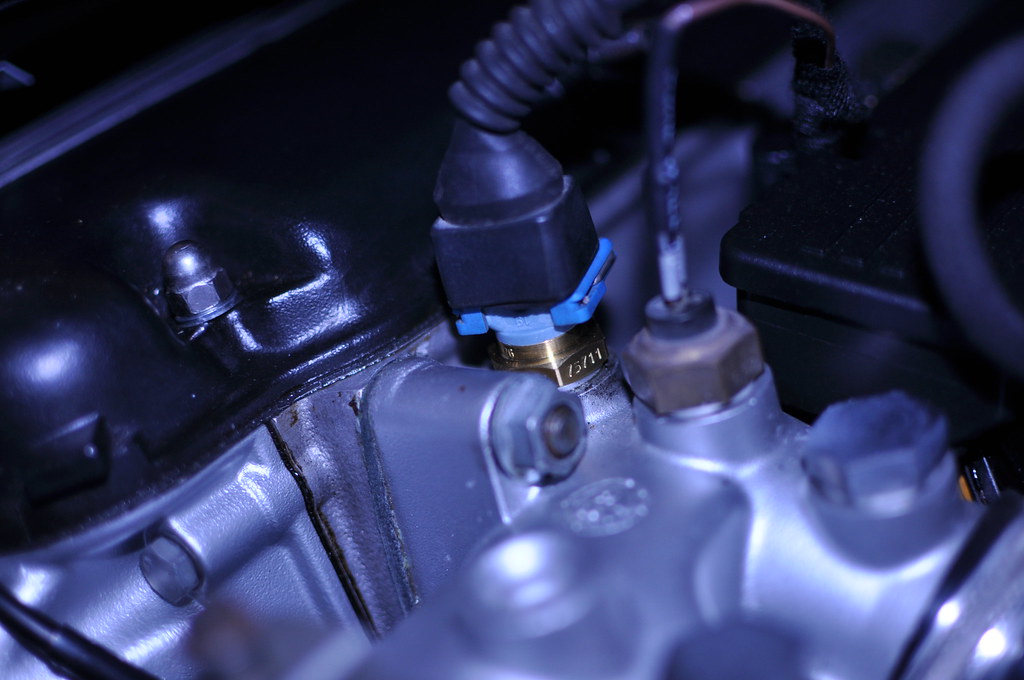

The injector service parts arrived and they were easily fitted.

Injectors were then fitted, along with the updated rail and new fuel hoses.

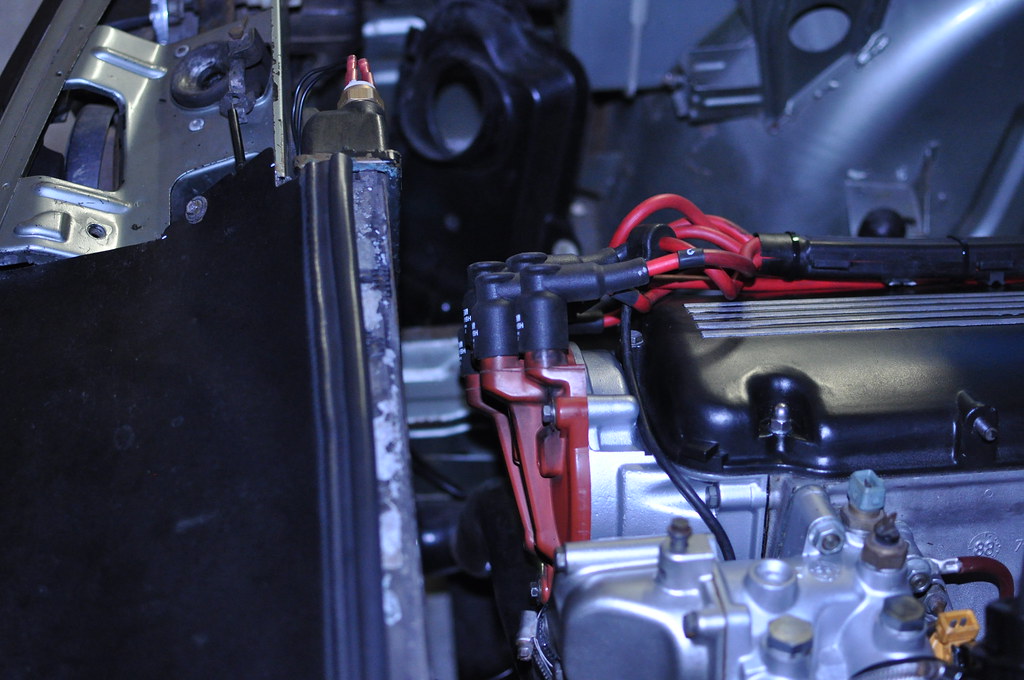

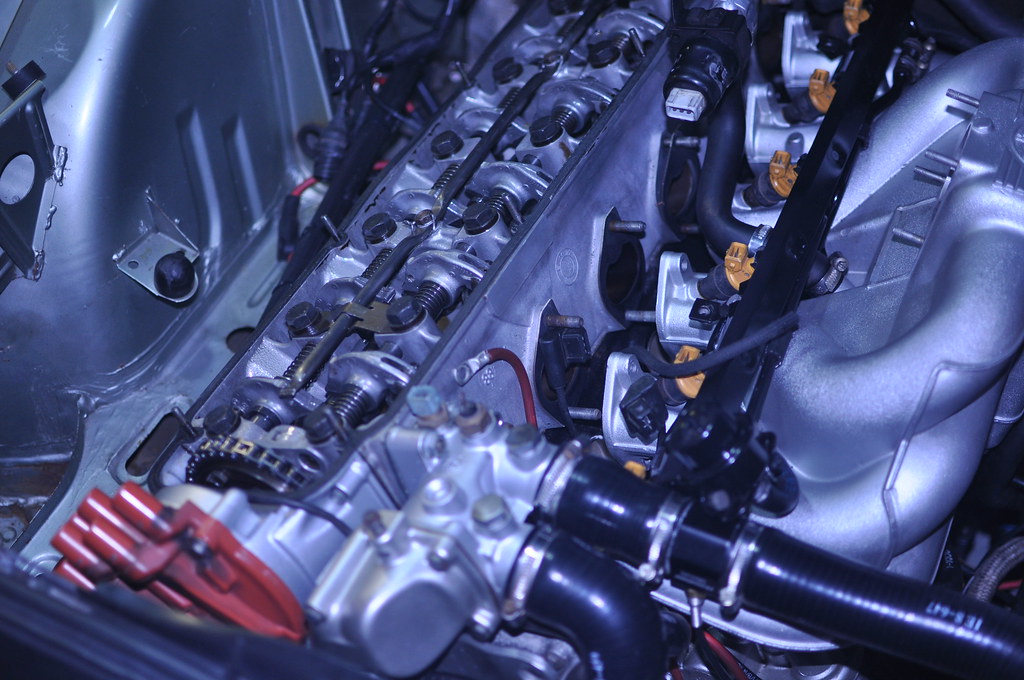

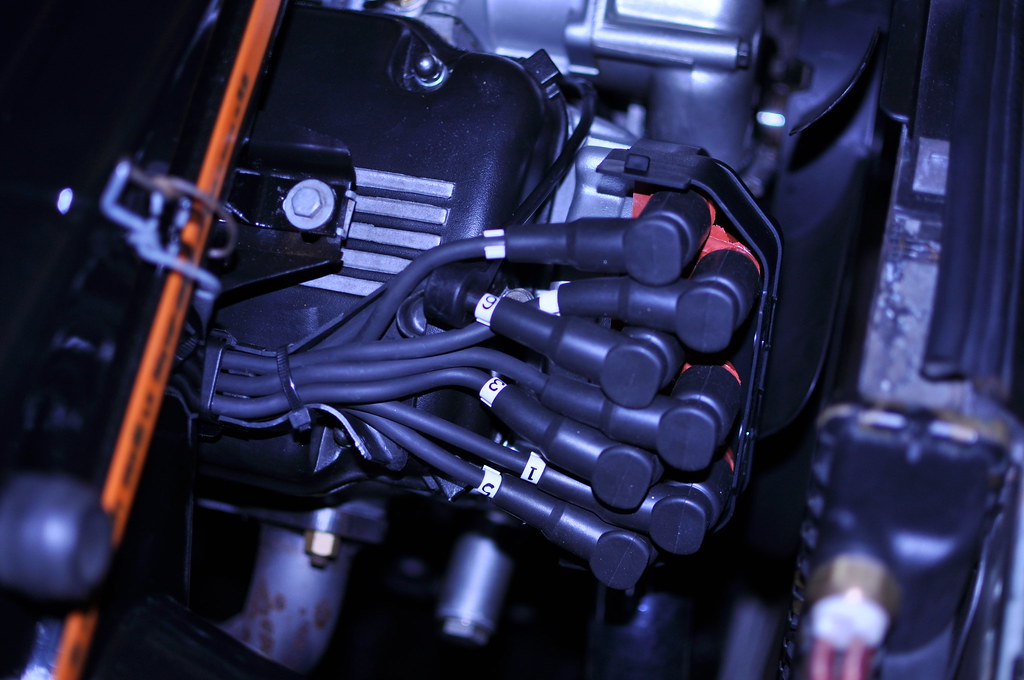

Motronic distributor drive, timing case and distributor cap were then swapped in.

The old ignition coil was mounted behind the headlights, i decided to mount the new coil on the strut town after making a bracket. Then loom also has to be lengthened as in E34/E32s the coil is mounted much closer.

Replacement vibration dampener swapped in, it has teeth to measure engine position, unlike the old one. I also cut the front rib off the pulley as its not need after deleting AC years ago.

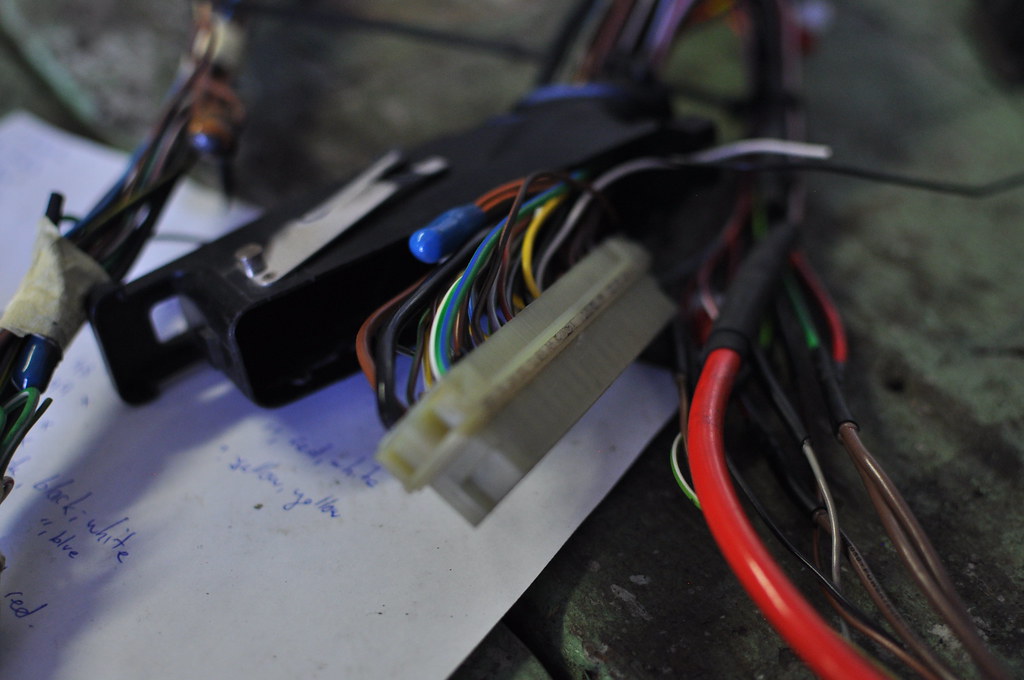

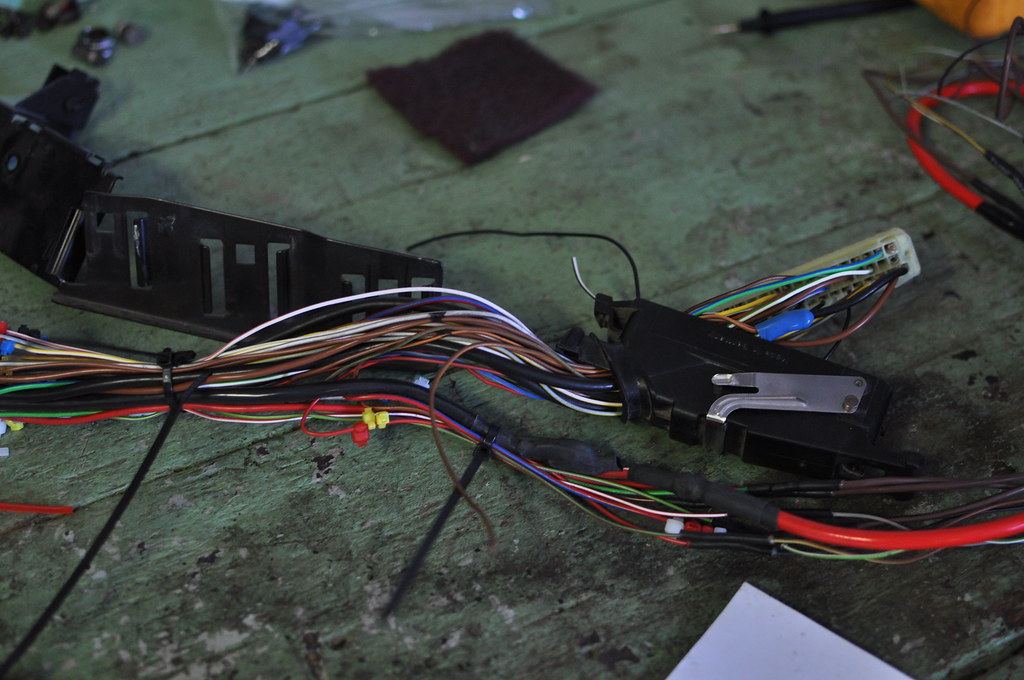

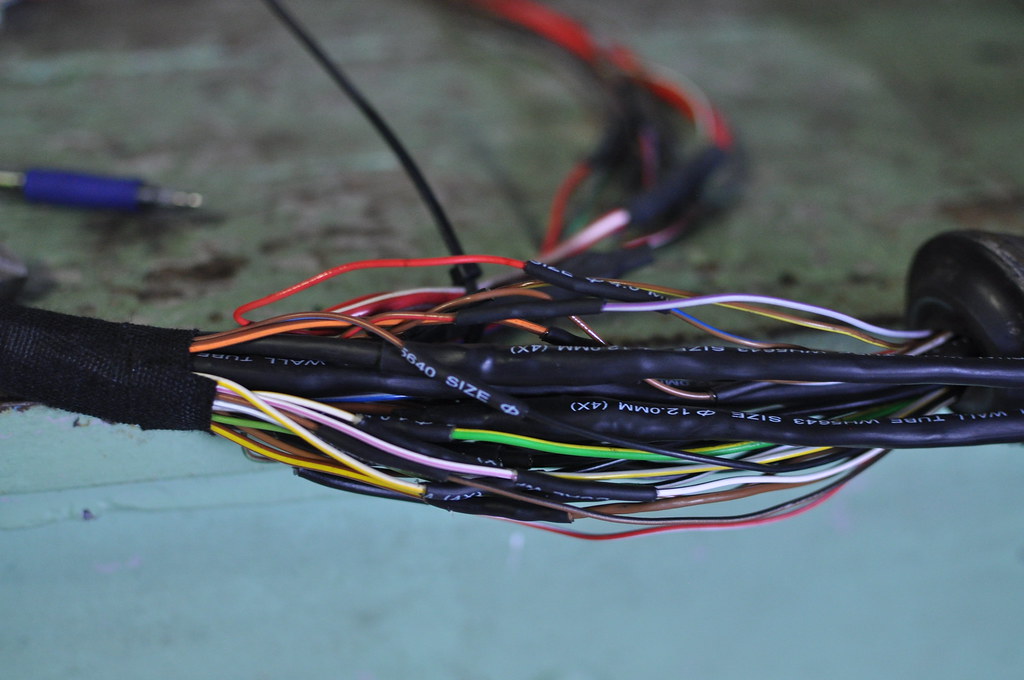

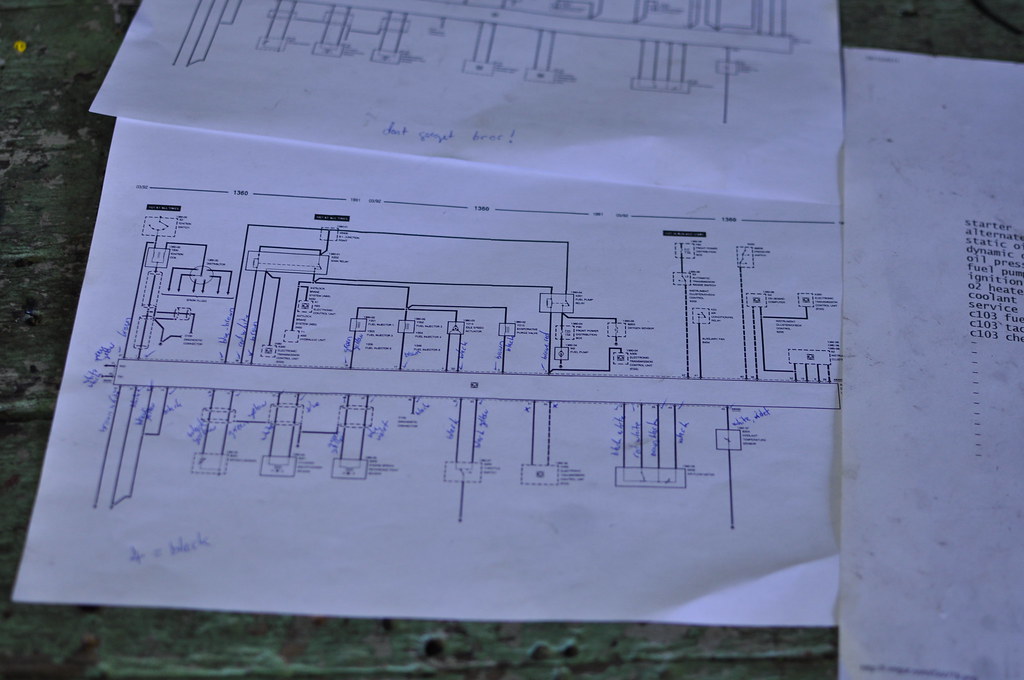

The most annoying part of the conversion was next. The loom that runs to the ECU is far too short for RHD cars, also the ecu plug is too big to fit through the factory firewall holes.. My first idea was to depin the connector, lengthen all the wires a couple of feet then crimp on new pins. But the pins were a bastard and wouldn't come out no matter what i tried. So a new connector has been ordered and hopefully that fits.

I'm hoping i can turn the key for the first time in a few days, hopefully it all goes to plan!Last edited by epearce; 08-19-2018, 05:24 AM.

Comment

-

As all builds do, it's getting strung out. With many hold ups, but I'm slowly getting to the end of it.

So to update where I'm up to..

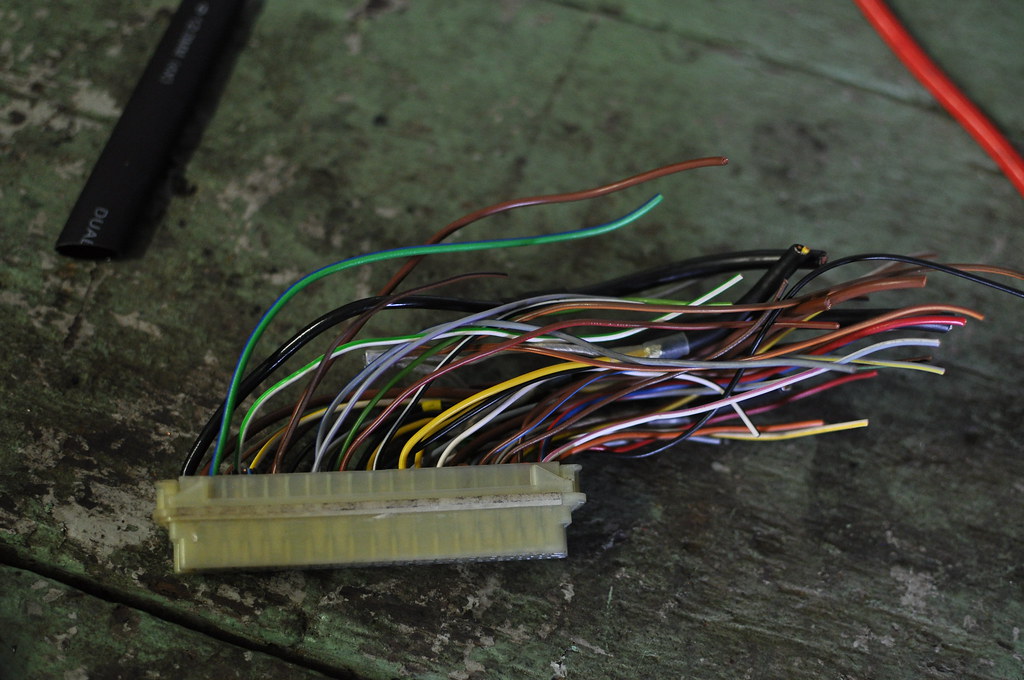

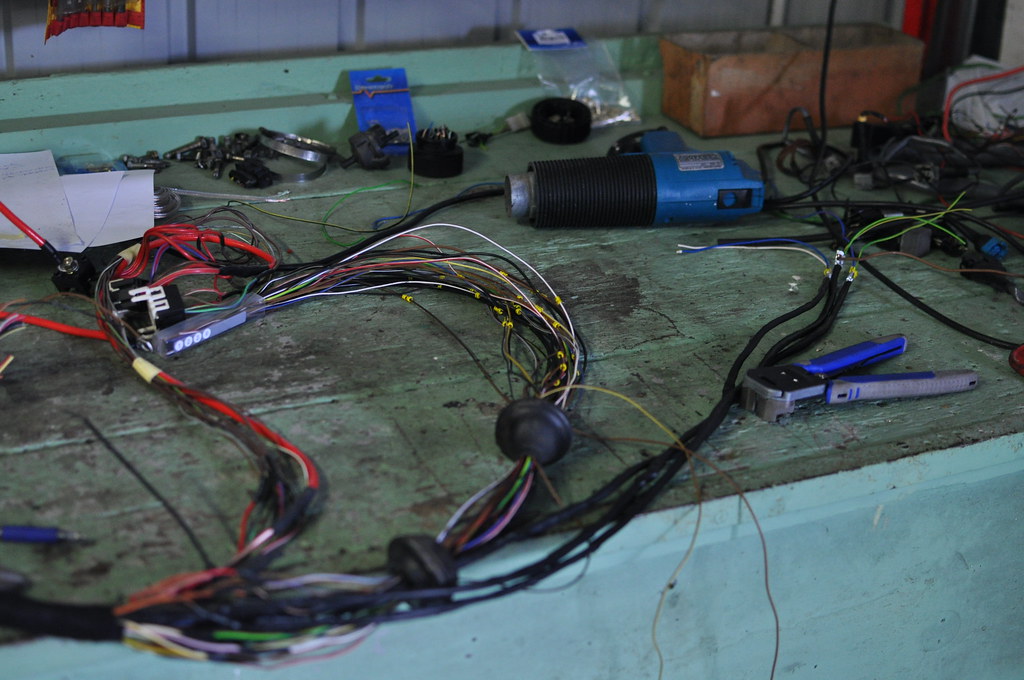

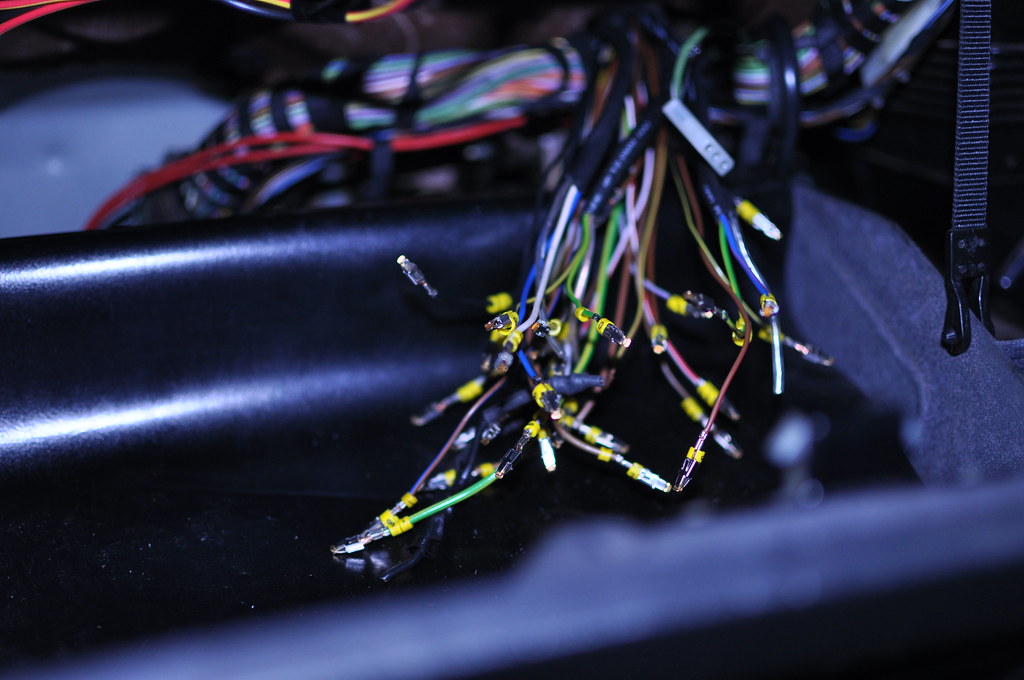

I cut off the ECU plug and lengthened the wiring so I can mount the ECU in the factory position with the wiring routed the neatest way possible. It also enabled me to fit the factory E28 grommets.

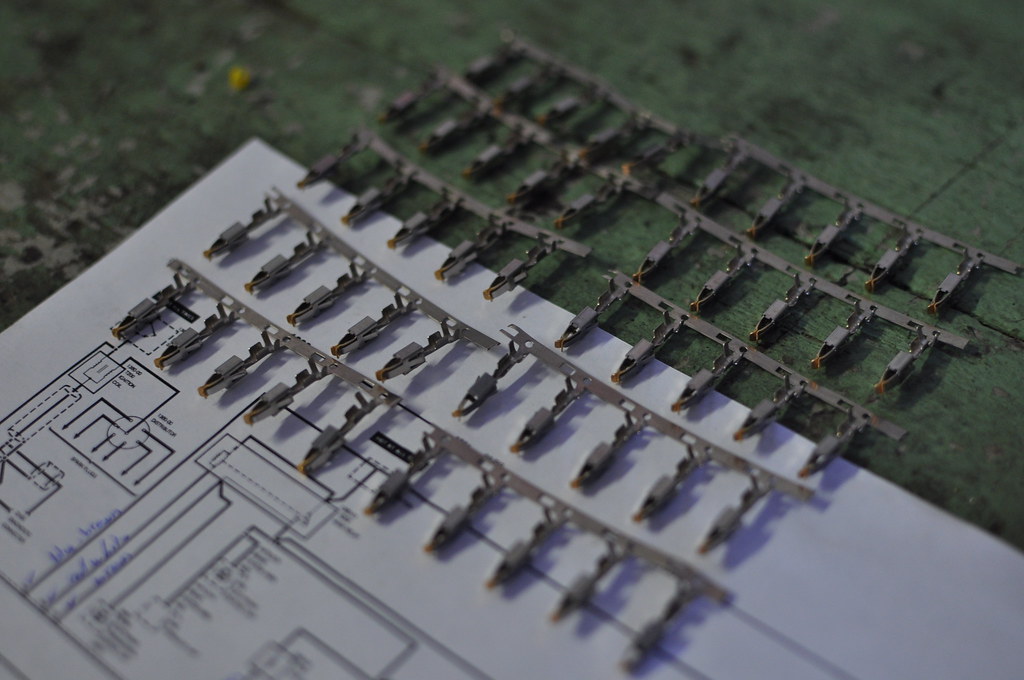

I continuity checked all wires back to their component before numbering, to hopefully ensure nothing gets pinned wrong in the ECU. Then crimped on new pins to all wires and ran the harness through the firewall.

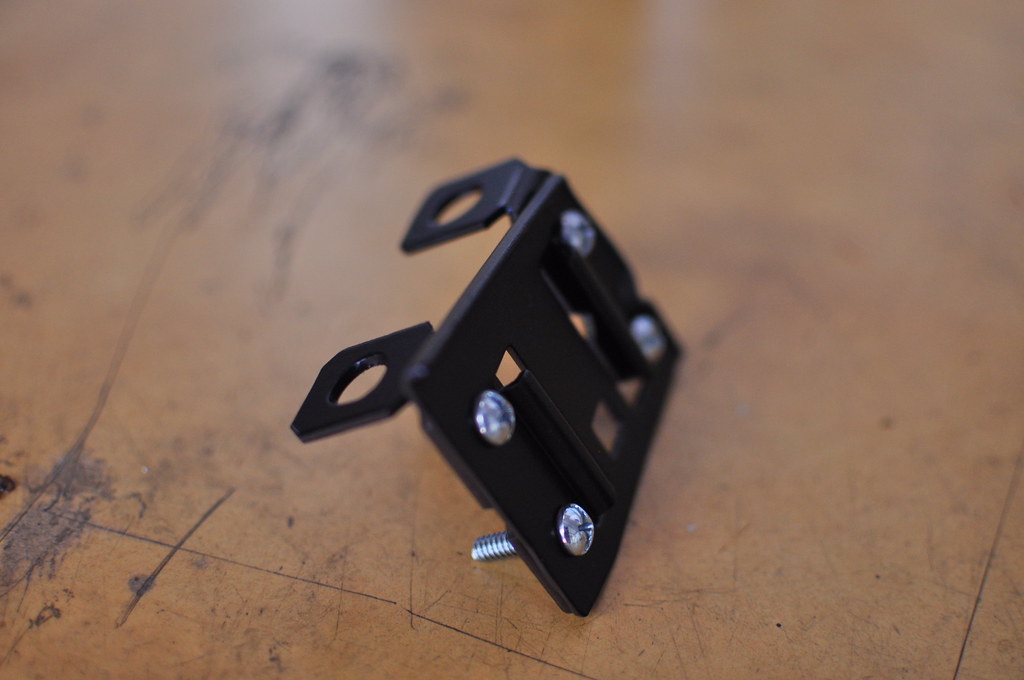

Continuing with the aim to keeping everything OEM looking as possible. I modified a E34 OBD bracket to mount the OBDI port in my chosen location.

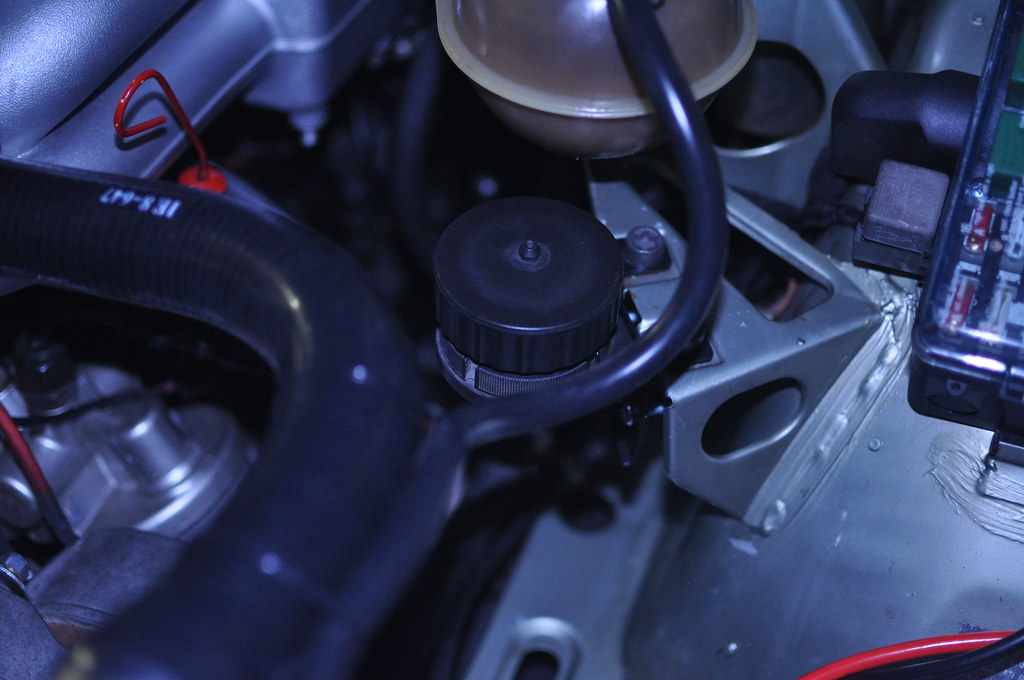

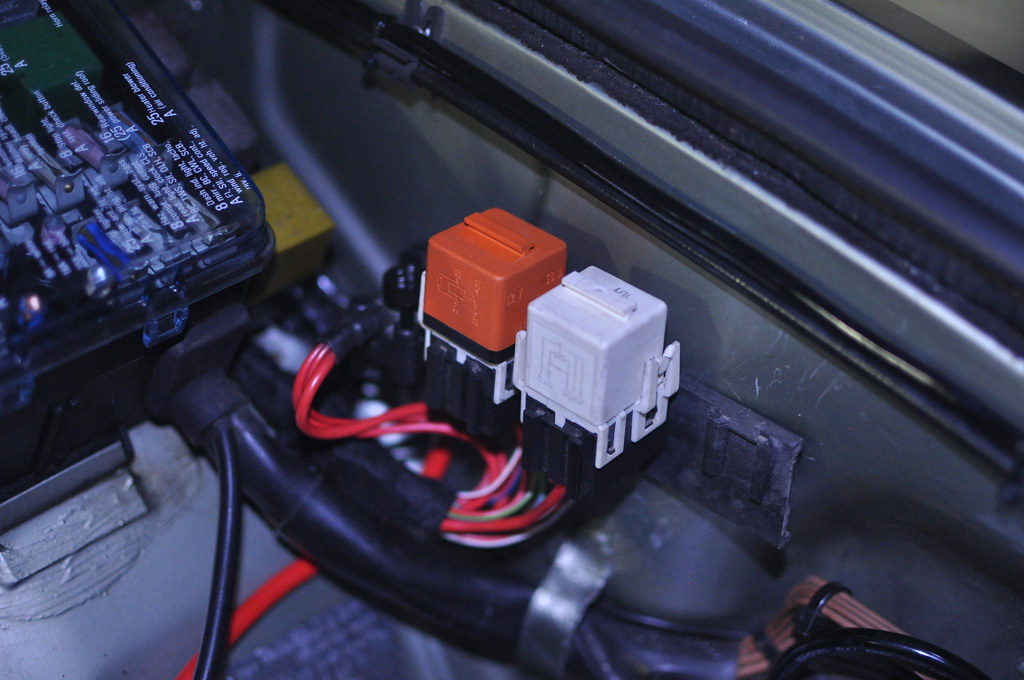

ECU and fuel pump relays were also mounted with the E34 bracket after lengthening the loom.

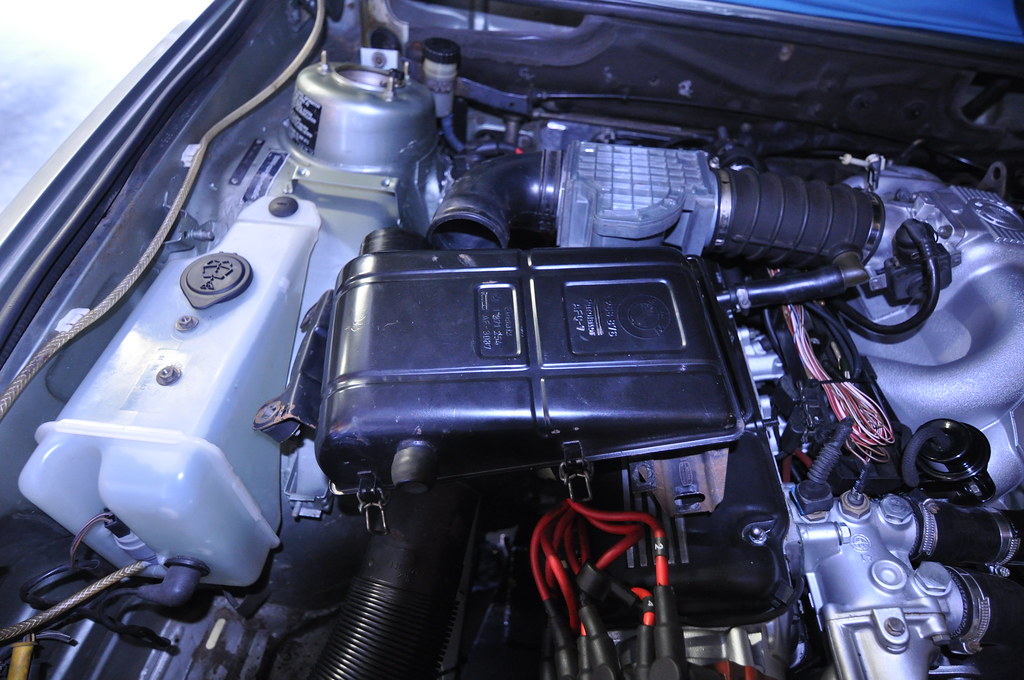

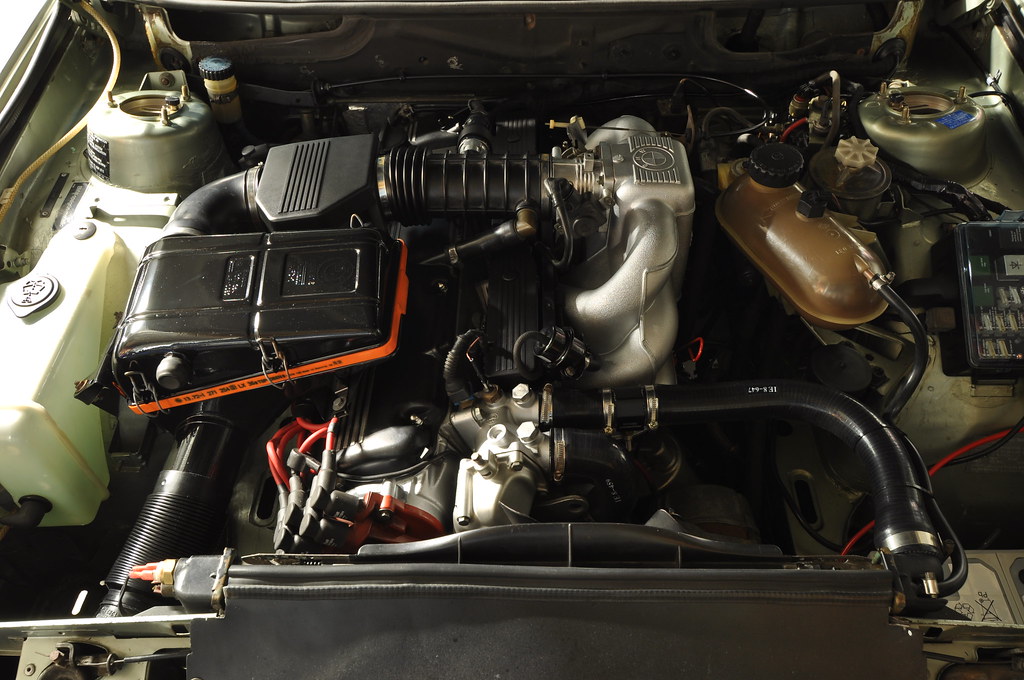

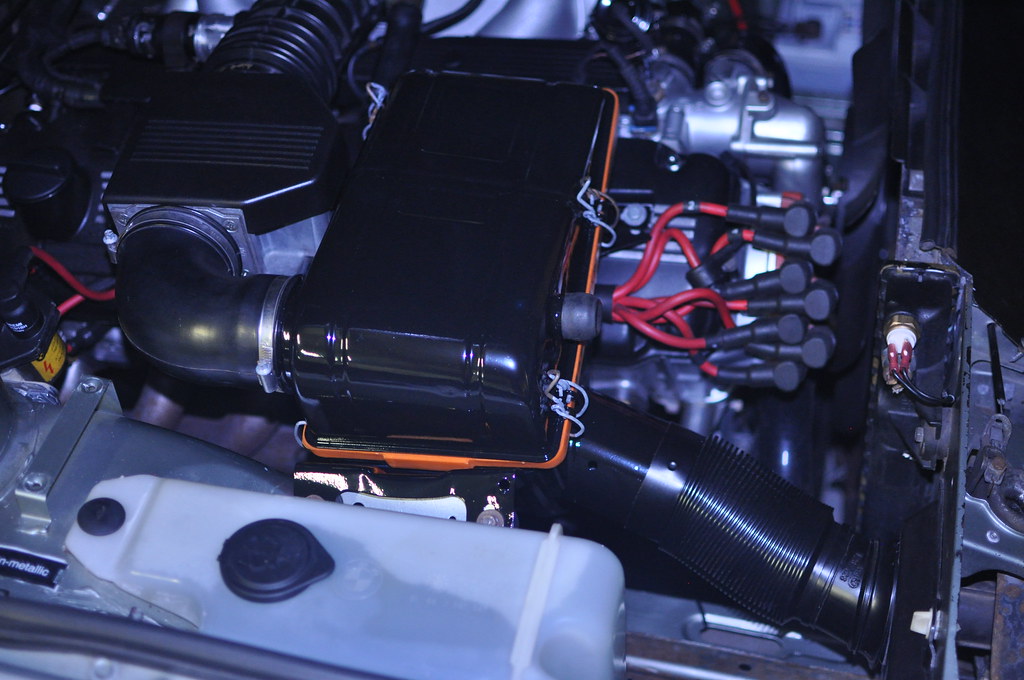

So then it was up to fitting the intake hoses, airbox, AFM etc. More problems encountered. First issue, I had nothing to mount the AFM too, but that was solved by sourcing a E28 535i bracket and then some modifications. Then it turns out the E34/E32 B35 throttle body to AFM hose was too short for me to be able to mount the factory airbox correctly.

But luckily there was an OEM solution, with an E28 535i hose being the perfect length. I also repainted the airbox whilst I was there.

Which basically completes the engine bay.. Still need to order a new ignition cap as the cover for that was cracked. So better photos will be taken when that happens. I chose to keep the factory airbox, even though some may say it is big, ugly and covers up half the engine. But i want it to look relatively factory under the bonnet and the factory airbox is not a performance limitation, so I saw no reason to go with something more modern.

Due to its limited use over the past couple of years I decided to suck the tank dry in preparation for start up, followed by some fresh fuel.

The new bosch 55pin ECU replacement plug arrived, much to my excitement as it was the last piece of the puzzle.

I went to push the wiring pins into their correct locations... only to find that they didn't fit. From my understanding there was only 1 variation of Bosch EV1 pins. But there was no way they were fitting. I got in contact with the plug supplier and ordered some pins off them, which I am still waiting to arrive. Fingers crossed these fit.

I'm hoping by this time next week it will be running.

Apologies for all the pics!Last edited by epearce; 08-19-2018, 05:26 AM.

Comment

-

So it was the beginning of February when I said it would be finished... hmmmm. Its now nearly the end of May and it still isn't done, not good.

What have I been up to over the last 3 months with it? Let me explain.

The correct wiring pins arrived just after my last post, so they were crimped on and it was engine start time.

Turned the key, nothing. No starter activation, no fuel pump prime. Zilch. What a disappointment.

After a couple of hours trying to figure it out, I called a friend who gave me some advice. Turns out the starter solenoid has two terminals, and with me fitting the wiring by feel as you can't see it, I had put it on the wrong one. So with that swapped over, I turned the key again. This time the starter activated and the engine turned over, but no fuel pump could be heard and the engine didn't start as a result. So back to the diagnostics, ended up jumping power to the fuel pump under the bonnet and got that priming.

Third attempt. Turned the key, it tried to start, gave it some throttle and it fired to life. But... it sounded like crap and as if it was smashing pistons on valves. Not ideal, my mood definitely changed at this point. I started pondering what could be, knowing I had the chain off the cam to swap the distributor drive. But I was pretty certain the timing was correct.

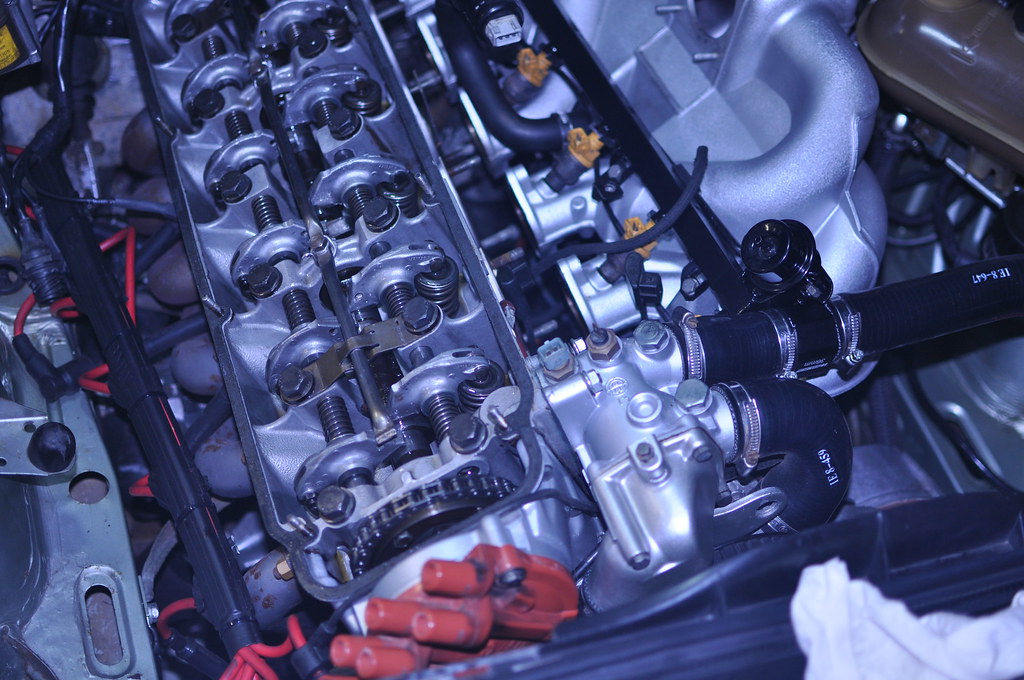

The following weekend I pulled the valve cover off to check timing, which thankfully was spot on. Then I decided to check valve clearances, discovering that cylinder 1 intake valve had a huge amount of valve clearance. So much so that it was too large to adjust even close to spec. I knew this could only mean one thing, the valve wasn't closed... I removed the spark plug, and shined a light. And what did I see? Cotton material, yes there was a rag on top of my piston, getting eaten by the valve. (insert worried face)

So I pulled the intake manifold off, hoping for some miracle. Found the rag half inside the cylinder, half inside the head. Turning the engine over, whilst pulling at the rag and it came free. Yay.

Fast forward a few steps and I poured some metho down the cylinder 1 intake runner and pressurised the cylinder with some air. Miraculously I saw no bubbles. How the valve didn't get crunched I do not know. I probably ran the engine for at least a minute when it first fired up. It was pretty burnt up and melted.

If you go back to my older posts you will see a black rag sitting inside the intake manifold opening to stop dust etc, it must have fell in and i never thought about it. Massive lesson learnt there.

With the engine back together, it was attempt number 4. With some throttle it fired up, with no strange noises present. But idle was rubbish, and it wasn't running smoothly. More diagnosis followed, found I had two wires around the wrong way for the idle control valve, swapped them and the idle improved dramatically.

Then i removed the exhaust and welded in a bung for the O2 sensor as my car came with none from factory.

I was naive to think fitting the oxygen sensor would solve the engines issues, because it made no difference.

My wideband was showing super lean mixures as soon as the warm up phase was over, with readings up to 20 - 21, add to that rough running.

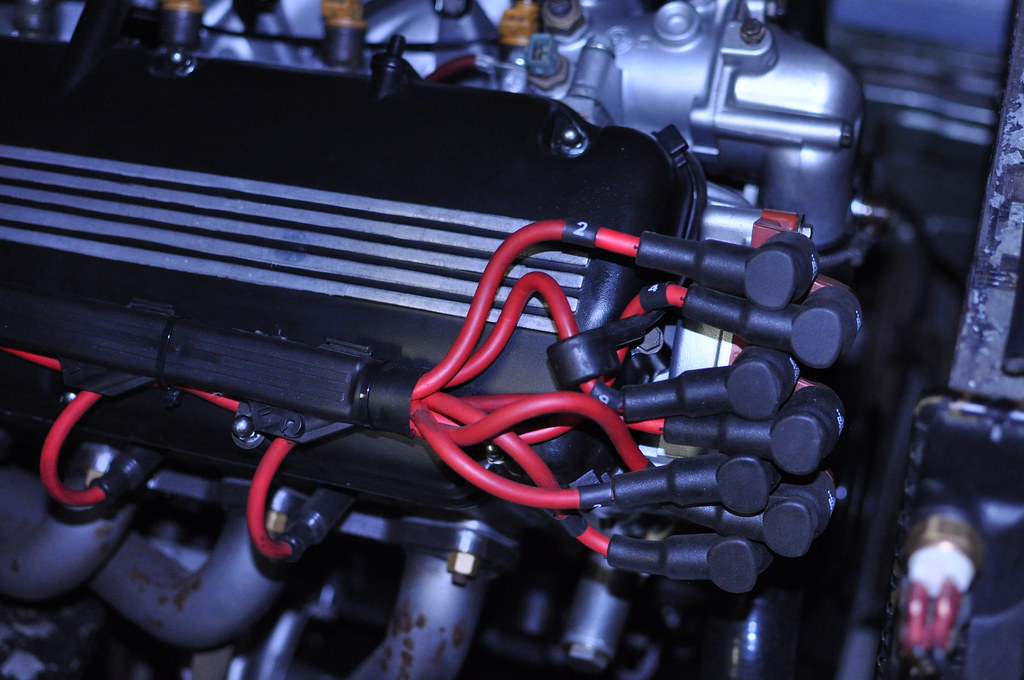

I checked the spark plug leads a first port of call and found them to be quite corroded, resulting in poor resistance being measured. Strange, as these were purchased from Ireland Engineering only a few years ago and it has been garaged ever since.

Decided to buy new leads, cap, rotor button, spark plugs, fuel filter and temp sensor. To rule out all those parts. The dizzy cap and rotor both came with the loom and were worn, the plugs were fitted when i rebuilt the motor along with the fuel filter, and the temp sensor came with the loom as well.

I finally got time to fit the above parts last week, UNI has been a full on semester, basically didn't have time to touch the car in a couple of months.

Today I got time to finishing it off and to be honest was quite nervous upon turning the key again. Sadly, it didn't start and run like a dream. It needed throttle to start, struggled to idle until it was warm and once warm ran very lean yet again.

Pretty gutted/disappointed with it all at the moment. Spent so many hours working on this over the years, and it just feels like it is getting me no-where. Wish I could drive it

I'm going to try to track down a tester car - e34 or e32 with this engine. That i can swap parts back and forth to find my issue.

At this point in time I can't see there is many things it could be. Spark side is all new apart from coil. Throttle position sensor tests as working, AFM tests as working but im sceptical. Maybe I stuffed up the loom, or maybe the ecu has an internal fault. I really have no idea.

Should have left it stock...

Thanks again for the above positive comments, apologies for the long post. Hopefully I can show you a running E28 sometime in the near future.

Comment

-

Install a fuel pressure gauge before the feed side of the fuel rail. If you're not seeing 37-43 PSI, look into a new fuel pressure regulator or possibly even a replacement fuel pump. Additionally, the factory AFM can be adjusted to correct the AFR if all else fails.

-1993 535i/5 NA-T

Comment

-

I will check it, but wasnt an issue prior to swapping this loom in. So in theory it should be fine.Originally posted by CSBolger View PostInstall a fuel pressure gauge before the feed side of the fuel rail. If you're not seeing 37-43 PSI, look into a new fuel pressure regulator or possibly even a replacement fuel pump. Additionally, the factory AFM can be adjusted to correct the AFR if all else fails.

I dont want to adjust the afm as that would just be compensating for an issue thats already there. It's basically a stock engine, so it should be able run in spec.

Comment

-

I had a similar issue on my recent turbo M30 build... #6 injector got turned upside down and wasn't actually plugged in when the loom snapped down onto it. Maybe pull your fuel rail with the injectors still attached, put it in a clear bag, then crank the car to see if an injector is stuck shut or not firing. It's either a massive air leak after the AFM or a lack of fuel based on your AFR readings.

-1993 535i/5 NA-T

Comment

-

I might give that a go, cheers! Pretty confident there is no air leaks.Originally posted by CSBolger View PostI had a similar issue on my recent turbo M30 build... #6 injector got turned upside down and wasn't actually plugged in when the loom snapped down onto it. Maybe pull your fuel rail with the injectors still attached, put it in a clear bag, then crank the car to see if an injector is stuck shut or not firing. It's either a massive air leak after the AFM or a lack of fuel based on your AFR readings.

Also just ordered a fuel pressure testing kit, so i'll be able to confirm that is correct.

I took it for a short drive prior to replacing the ignition parts above, on cruise and accelerating AFRs were 19+. It had zero torque.

Comment

-

Six months after I pulled the engine bay apart to begin this project there is finally light at the end of the tunnel.

Started with replacing the coil with a genuine Bosch part to rule that out, also they are super cheap. It didn't solve the issues, as expected, so I continued on.

To rule out compression and fuel pressure I bought a kit for both and confirmed both were spot on. Also a big relief to find cylinder 1 wasn't down on compression after the rag in cylinder dilemma. However when I pulled all the spark plugs out I found the plugs from both cylinder 1 and 6 much cleaner than the other cylinders. Making me think that the injectors weren't firing properly on those cylinders. After pulling the injector loom off, i confirmed they were getting injector pulse signal and the injectors operated when given power. So I put it down to a poor connection on the injector connectors.

Conveniently a couple of weeks ago I received a Facebook message from a local guy I'd never met asking for some advice for his recent BMW purchase. Turns out he purchased an E32 735IL, which is the model of BMW this loom/engine management is from. A few messages later and I had organised for him to lend me his car to help diagnose mine.

The main issues I wanted to solve with the help of this car were; idle control motor is not operating at all, the fuel pump doesn't receive power with ignition on or when cranking.

By checking wiring signals on the E32 and comparing them to the ones on the E28 I determined that I must have had a short to positive on the control wires of the idle control motor. My diagnosis was correct and I was lucky to find the short very quickly just behind the wiring connector.

The fuel pump activation was a little harder to diagnose. As I'm using an auto ECU I presumed this had something to do with my issue. But after giving the ECU the correct signal to replicate being in neutral/park it still wouldn't activate. A couples hours of comparing wiring between the two cars later, I found that the ecu wasn't grounding the fuel pump relay, which is meant to happen when cranking the engine in the neutral/park position. All my wiring I trusted was correct, so I thought I'd swap in the donor cars ECU to see if the ECU was at fault. What do you know, it fired right up!

It was a very happy moment, after all the hours over the last 6 months put into this swap to finally year it running spot on. I was nearly to the point of believing it was never going to happen. Glad I never gave in.

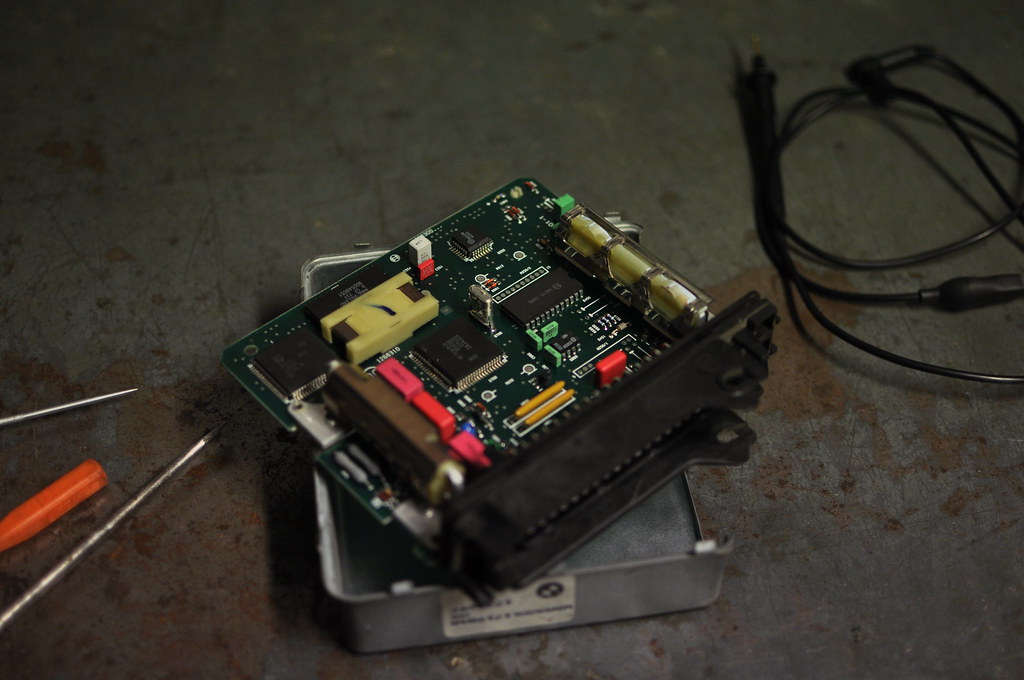

Currently have my ECU back in it, with the fuel pump relay jumped so it still fires up. I might try and pull the ECU apart and see if its something I can fix before I buy a new one.

I took it for a short 5km drive before the rain came and it met all expectations. AFR's were spot on under all rpm ranges, no stalling, no hesitations. Success at last.

So keen to begin the next instalment!Last edited by epearce; 08-19-2018, 05:30 AM.

Comment

-

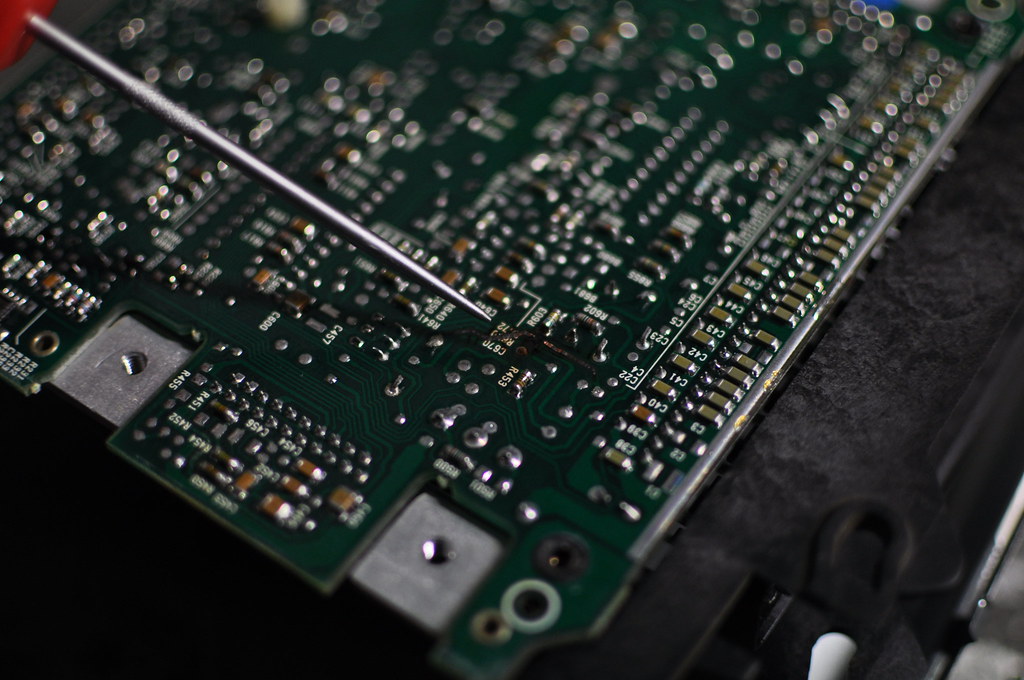

Pulled the ECU apart today, as expected there was a burnt out circuit for the fuel pump signal.

I'm sure its fixable, but it's not something my soldering skills would probably fix. So I picked up another ECU off a friend today. Hopefully this is the end to my engine woes.

Comment

Comment