Announcement

Collapse

No announcement yet.

1969 simca 1118

Collapse

X

-

thanks dude! guess that means I need to step my game up!Originally posted by Ginge View PostThis is on another level, you also made it to my Epic build threads thread over here

Restorations, Rebuilds & Projects. - Epic Build Threads - I often get bored and find myself stumbling on threads from all over the place that just blow my mind, be it with big money builds or just someone in a garage doing on their own. Thought i might try and keep this upto date as and when i find them and maybe you...

Restorations, Rebuilds & Projects. - Epic Build Threads - I often get bored and find myself stumbling on threads from all over the place that just blow my mind, be it with big money builds or just someone in a garage doing on their own. Thought i might try and keep this upto date as and when i find them and maybe you...

Looking forward to seeing more!

Ginge

Comment

-

The most rad Simca 1118!

Wow, you are really working on this!!

Where'd you get those cool looking new brake lines?

And, can you make two of everything, one for me??

Best Regards,

Matt Cotton

Lake Parsippany, NJ

http://www.flickr.com/photos/njsimca/6113183308/

Comment

-

Wow.... Not alot of people know how much work goes in to making a matrix for a car parts never mind pouring liquid mold.... this is impressive!

we kinda do same thing except where you use wood we use clay and wax.

deff subscribed! this just became my favorite build on stanceworks.

Comment

-

Haha thanks. I make a male mold of the thing I want to cast out of wood, then pack sand on either side of it with a layer of talcum powder in the middle so I can separate the two halves. after I separate them, I cut two "tubes" In one half as pathways for the molten alloy to pour down and the other to indicate the alloy level in the mold. Clear as mud?Originally posted by ThatEF9kid View PostAwesome man, How do you make these parts though i dont really understand haha

I'll try to put together a real deal write-up soon.

Hey Matt, nice to see you here!Originally posted by njsimca View PostWow, you are really working on this!!

Where'd you get those cool looking new brake lines?

And, can you make two of everything, one for me??

Best Regards,

Matt Cotton

Lake Parsippany, NJ

http://www.flickr.com/photos/njsimca/6113183308/

your 1118 looks great!

I might end up with a few extra casts, so I'll let you know!

Those brake lines are replacements for a vw bug and are way to long. I used them to free up the brake cylinders.

Thanks. I'm pretty excitedOriginally posted by Scotrod View PostMy Hats off to you dude, Ive always wanted to see one of these done right. Im Subscribed.

Yeah after casting my first few parts, I stop and stare at the most common parts and try to figure out what the mould or core mould looks like.Originally posted by Bystrov View PostWow.... Not alot of people know how much work goes in to making a matrix for a car parts never mind pouring liquid mold.... this is impressive!

we kinda do same thing except where you use wood we use clay and wax.

deff subscribed! this just became my favorite build on stanceworks.

It's been raining everyday after school the past week so couldn't use the foundry. But, I cut my first butterfly!

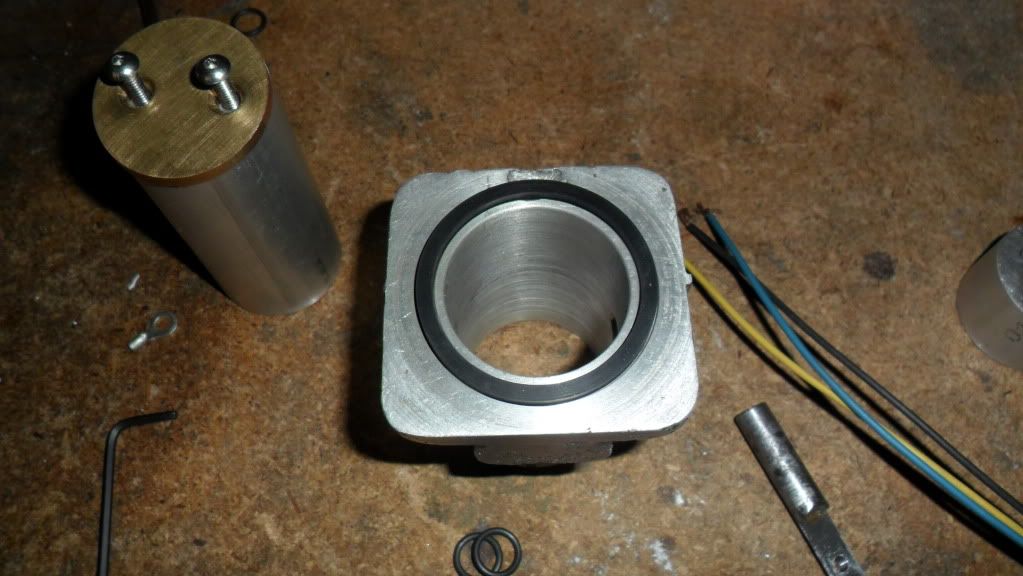

Made a jig to cut a plate of .125 Brass at 15 degrees. I first cut a square of Brass, drilled #8 holes .800 off center, sandwiched it between the aluminum barstock, and cut it down to the final bore I wanted.

WOT. wow .125 brass is thick. I might taper the plate down to streamline it a bit, but hey, I just want to make 100hp! lol

This is the parts break down. Skateboard bearings all the way!

I'm not to happy with the surface finish of the bore. This alloy is cutting much stickier than other cast aluminum I have machined. I have a small convection oven that I'm going to try to use to heat treat the alloy.

Cut an o-ring groove in the flange, I will also cut one in the manifold.

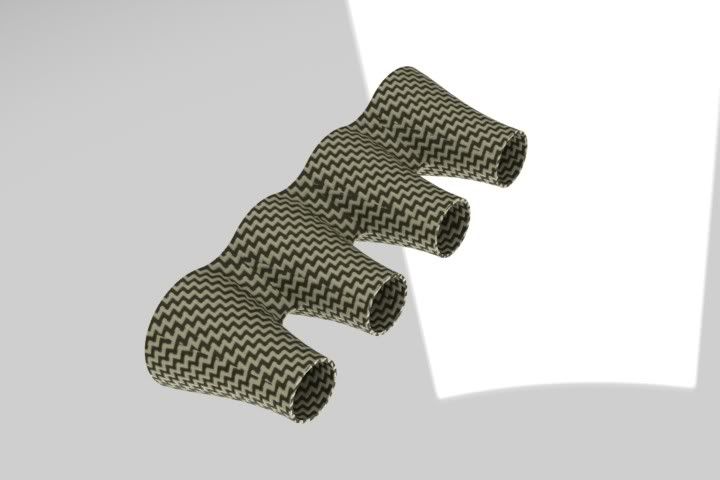

Here is a Solidworks drawing of the plenum I want to build. This would also have a flange at the open end to bolt up to an intercooler core.

Comment

-

Comment

-

That Datsun Build was definitely an inspiration. Yeah I built it all from scratch. I mixed up my own refractory and made a mold from an old piece of ductwork. My source of air is mainly a hair dryer.Originally posted by ollycarbs View Postman that's awesome! i saw a guy on Build Threads doing his own pipes for a Datsun, i was just speechless!

What you are doing there is great!!! how did you build the "oven" where you are burning raw material? all is DIY or kinda?

subscribed!

keep up the good work!

Comment

-

i love DIY and different, custom stuff, and this thread seriously delivers! well done man, keep it up! sigpic

sigpic

Midmounted Mazda Minitruck video build thread - www.youtube.com/pimppalacecustoms

Build pics and randomness - www.facebook.com/pimppalacecustoms

Long term project 340i (Lexus V8 powered e21) http://www.stanceworks.com/forums/sh...highlight=340i

Comment

-

Thanks guys, I'm glad you appreciate the work.

I got the rest of the throttle bodies cast last night and this morning ( being one and the same)

I have poured about 12 by now, but have messed up 7 of them. I had a really sucky time figuring out what the problem was, as it looked like the mould wasn't filling all the way, even though the riser was full. It turned out the sodium silicate core was out-gassing and creating a bubble in the mould, so I ended up baking the cores at 450F for an hour in the oven and it seems to have eliminated the problem. As Edison said about the light bulb: "I never failed; it just didn't work 1000 times!"

Hoping to cast the manifold tomorrow!!!!

Also made a mould for the throttle arms. I tried pouring one and seemed to work okay

Comment

-

Thanks dude!Originally posted by Speedbump View PostDamn, lot of work! Respect! My dad would love this he used to own one back in the 70's!

Didn't get the mani poured yet but got a few throttle arms cast and figured out

but got a few throttle arms cast and figured out

Also cast a little badge to see how lettering would turn out. A lot of undercuts still, but getting there! I want to incorporate some script or logo into the manifold. We shall see what this weekend holds for working on the car.

Comment

Comment