serious work

Announcement

Collapse

No announcement yet.

2003 Mustang Cobra convertible getting e-level setup!

Collapse

X

-

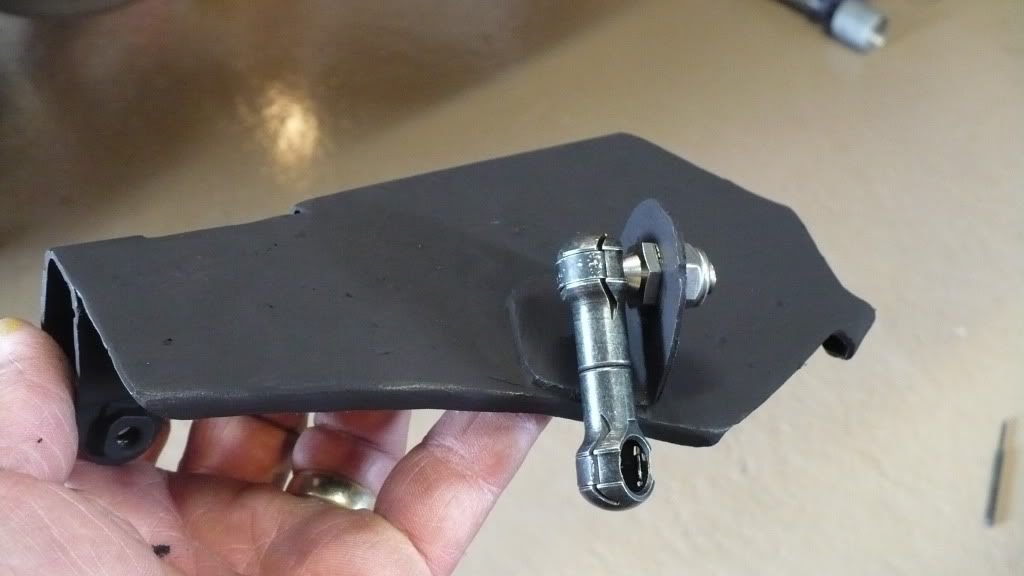

This afternoon, Michel finalized the design and fabrication of the plates for the rear ride height sensors. We messed around with sensor location and pushrod length for a while to find the best solution. Some minor adjustments will be made upon final assembly, but this is essentially what it will look like. You'll notice that the pushrod length is different in the two pics. The length we determined to be best was in fact no length at all, i.e. the two ball cups will butt up against each other.

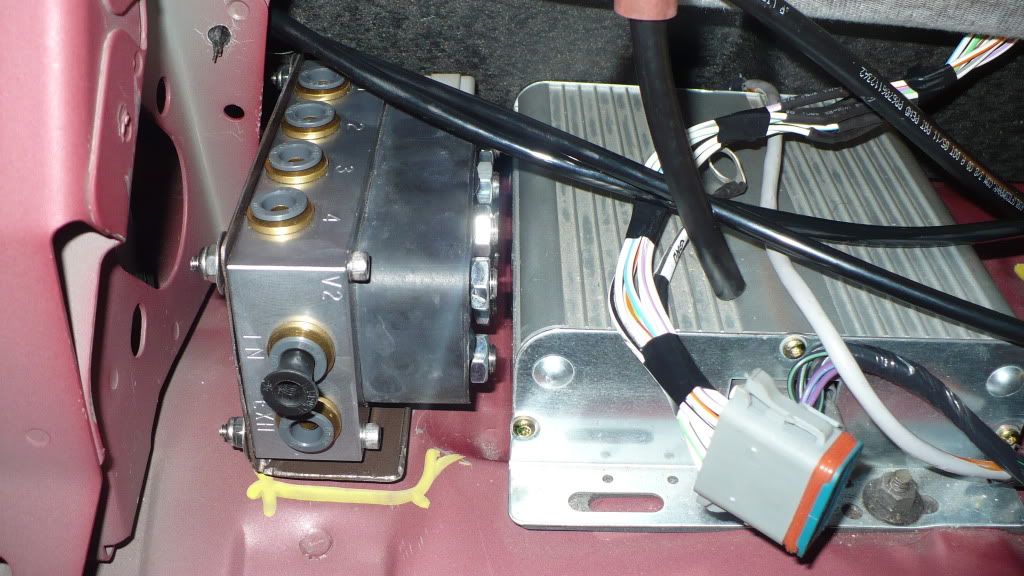

I finished up the positioning of the VU4 manifold, and epoxied it into place. I was then able to finalize the routing of the rear air lines. the right rear wasn't as bad as I predicted. It basically just comes up out of the floor above the spring cup and makes a U turn directly down into the VU4 port. Both lines were secured with the red hose and tie wraps.

I also drilled holes for the sensor wiring from the trunk into the wheelwell behind the shock, very near to where the sensor will be mounted. This reduces the length of wiring hanging around outside the car, and it will all be concealed behind the trunk panels when reassembled. The end of the wire harness can be seen in the first pic of this post as well. I disassembled the end connector because its size was way too big to fit through any hole I would ever drill in my car. Once again, it is protected by our good old red air hose where it goes through the body.

We decided to put a rear wheel on the car so we could see what our upward travel limit was. We just jacked up the tire till it maxed out. You can see that most of the rubbing is occurring at the joint where the bumper meets the quarter panel. We may be able to reduce the interference, but the car won't go much lower without it occurring even worse. Just seeing the huge wheel and tire stuffed up into the fender was awesome! Usually I'm driving over a bump when the suspension is this compressed, so I never get to see it. The clearance issue I posted last night has been resolved.

So that's where we're at. We've both got personal obligations tomorrow, so we may not get back to it till Wednesday. If we feel like it, we might be able to get a few hours in tomorrow evening. Next up, we will finish the rear plates, and probably get cracking on the dual compressor install. I did spend a few minutes peeling the stickers off them and removing the adhesive residue today, so they're all nice and shiny!

Comment

-

gettin' there!E53 4.4 Sterling Gray Metallic

E36 M3 Mugello rot

GEN2 TUNDRA CM

https://instagram.com/carlmichaeljohnson/

Comment

-

-

Thanks guys, your interest is helping us stay motivated. We didn't work on the car today, but I can update you on a couple of other things.

To swap rear springs on an IRS-equipped Cobra or IRS-swapped Mustang is very easy. Remove the exhaust, remove the two lower shock bolts, put a jack under the center rear of the IRS subframe, and remove the two rear IRS subframe bolts. Then just lower the jack until you can pull the springs out. Anyways, when we were raising the IRS back up after removing the springs, it slipped off the jack and dropped down, and it overextended the left rear brake line. The line started leaking brake fluid, so basically the car is undriveable until the line is replaced. Today I located a set of Russell braided stainless brake lines that I should have in my hands tomorrow. The kit has lines for all 4 corners. I'll do the rears because they are necessary (can't do just one), but I might not do the fronts if we run out of time.

We also had to think of a solution for attaching the sensors, because they are being mounted on the rear framerail. It's like a 2"x3" (roughly) hollow steel section, so our options are either to drill out both sides to gain access for a nut on the back side, or use a Nutsert. We decided to try the Nutsert option, and Michel was tasked with trying to find some locally today. I haven't talked to him, so I don't know if he found some. For those that don't know what a Nutsert is, here is a pic and a link:

Fastenal Nutsert

I emailed Mike at Accuair with a few questions we had about the ride height sensors. We needed to know what happens if we go beyond the oft-repeated 2.75" maximum travel for the sensors. With our current setup, which is the only option we have anyways, we have roughly 3" of travel at the sensor. The sensor allows for almost 4" of travel between the physical stops, but Mike says there's some kind of dead spot at either end of the range that the sensor won't be able to read properly. I guess we'll have to see what happens when the car gets out on the road.

That's all for now. Tomorrow I have to go buy a couple things we will need, and I should have my brakelines in by mid-afternoon as well. Stay tuned.

Comment

-

We got a late start today, but we feel we made some good progress, and we have a clear view of what needs to be done tomorrow, so we should get some good progress tomorrow too. I have a deadline of Friday night in sight because of the yearly All-Ford show on Saturday.

Michel finished working on the rear ride height sensor plates today, and they look and work great! The driver side is bolted onto the car and checked off the to-so list. The passenger side was still too tacky to work with, so we'll let it dry overnight. Michel shot them with black header paint, followed by a coat of rubberized undercoating. This will help to prevent them from rusting, and reduce rattling should they ever come loose.

We also made a final adjustent to the ride height sensor positioning to get the travel more centered in the sensors' range, and I got my hands on some Nutserts from the shop at my work. They will do the job perfectly, but the tool that installs them is missing a key component, so Michel fabbed up something that will do the job. We will try it first thing tomorrow. I got my brake lines today and installed the rears right away, just to get something checked off the to-do list. We just have to bleed the brakes after we swap out the front lines.

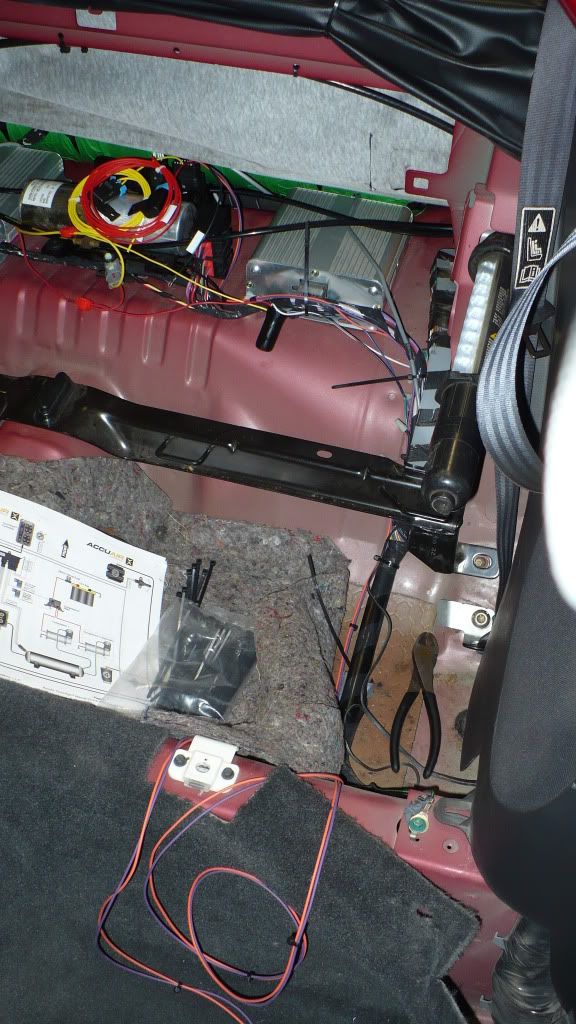

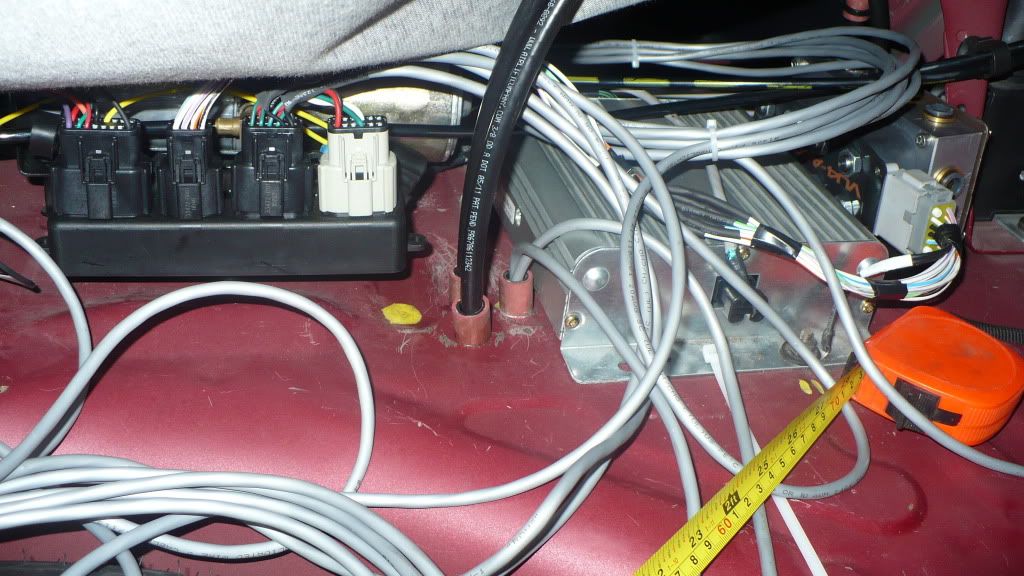

Moving on to bigger items, I started working on the wiring harness for the ECU and air compressors. Two wires (Ignition and Lighting) needed to be routed from the ECU to under the dash, so I ran them along the main wiring harness on the driver side floor. Tomorrow I will tap them into the wires near the fuse panel and that will be done. Michel ran the wiring harness for the Touchpad Controller down the center of the car. I don't have a permanent location in mind for the Touchpad yet, so for now it will reside in front of the shifter.

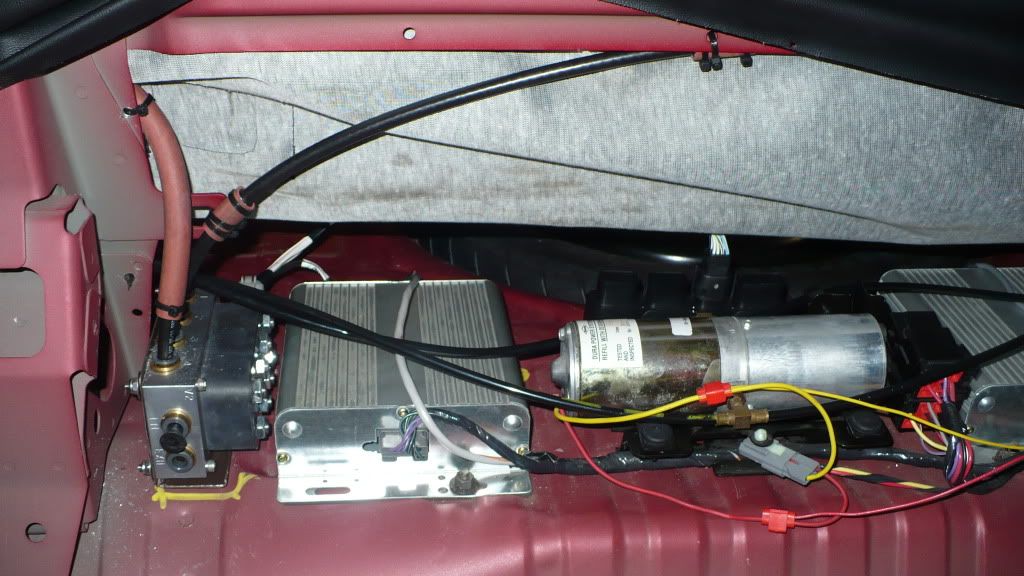

I also mocked up the positioning of the air tank and compressors. The main restriction is the length of the braided stainless lines that go from the compressors to the tank. I know I could always get longer ones, but I'm sure they cost more than I'm willing to spend. We ended up mounting the compressors on the inner fenderwells. Michel deemed it necessary to fabricate some more mounting plates for the compressors, so he got to work on that while I was fiddling with the wiring harnesses. I think the location we chose for the compressors will look really cool once it's done. We will probably have to cut clearance holes in the side panels of the trunk liner to clear the heads of the compressors, so they'll be peeking into the trunk but not fully visible.

Another thing I took care of was to assemble the top plates for the front airbags. Couple of washers and nuts and an air fitting on each, and they're ready to go into the car.

As I stated, we have a clear idea of what we will do tomorrow. First on the list is to get the rear suspension buttoned up. We also need to get the air system up and running so we can get the car on the ground and turned around in the garage.

Comment

-

Today we got a lot of work done, but we didn't get the rear end off the jacks, and the front is still on the ground. We did complete a few tasks that will enable us to get the front done a little quicker.

I started off by finishing the wiring under the dash, and I put the interior trim pieces back in place. I also worked on the wiring for the compressor relay. I decided to mount it on a metal tab on the driver side between the rear seat and the trunk, where everything else except the tank is going. It's starting to get crowded in there, but I don't expect to have to go in there anyways. I ran the big power wire for the compressors from the battery to the relay along the underside of the car, and brought it up through the grommet that the ABS sensor passes through.

We finally got the rear suspension all back together, and we had to extend the pushrods because the shock absorber was forcing the A-arms lower than they were when we mocked it up. The shocks also reduced the top of the travel slightly, so it worked out well. We added the brake line clamps to the same single bolt that holds Michel's fabricated plates to the upper A-arms, making it a simple and clean setup. The Nutserts for the sensors worked like a charm with Michel's fabricated installation tool.

Michel's fabricated compressor brackets were all painted and ready to go into the car, so we got them installed.

We polished up the exhaust tips while they were off the car and made a couple of small fitment adjustments to the exhaust system when we put it back on the car. The girls came by to lend a helping hand. It's fun to have them around in the shop, they came in handy when running the big power wire through the front inner fender and up through the grommet!

Accuair's products are really top-notch. If the wiring harnesses weren't all properly labeled and with different, non-interchangeable connectors on them, I'd have a hell of a time keeping track of what's what. Every time we run a harness or air line through sheetmetal or near sharp edges, we use our trusty red air hose. Also, to pass the sensor harnesses through these holes, it's necessary to dismantle the connectors and pass the wires through the hole then put the connectors back on when you're ready to plug them in. Here you can see the pair of front sensor harnesses disappearing through the trunk floor to be routed forwards together under the car along the fuel lines. The other two holes have an air line each, with each line running up its own side of the car. The passenger side line follows the fuel lines as well, while the driver side follows the big red power wire.

I also got all the air tank fittings in place with teflon tape. Michel has an idea for a tank mounting bracket, because it can't be bolted straight to the floor due to its location partially over the spare tire well.

We noticed that my right front tire is worn unevenly down to the cords on the inner edge while we were under the car. We'll have to investigate the cause of that. A new tire (or two) and possibly a ball joint wasn't on my to-do list (or in my budget), but safety first.

Tomorrow will be a big day. We are still aiming to get it done for Saturday's show, but I won't be too sad if I don't make it. As long as I can get to my family BBQ on Saturday afternoon, I'll be happy. I'll stop making predictions as to what we will be doing tomorrow. I could just sum it up by saying that tomorrow, we need to do everything that's not done yet.

Later.

Comment

-

OK I know Phil didnt do an update so I'll give you guys one.

First we worked on the car until 4 am last night.

We finished the front end.

Mostly trying to bleed the brake system.

Today, we finaly bled the brakes and buttoned up the lines and sensors under the car .

Anyway we took a lit of pics so Phils update will explain much better.

Phil just left with the car going to a family Bar-B-que with a huge smile on his face.

We calibrated it, tested to see what was rubbing and the car barely touches the ground and is drivable when air is out.

not even rubing when the front wheels are fully turned from side to side.

I'm impressed.

Got to say that it was quite a project.

It is the most satisfying project I have taken so far.

Comment

-

2fup is a local Montreal Mustang friend who is contemplating some Accuair for his 37 ford. Good to see you here Wayne!

Ratfink pretty much summed it up. We have a kew kinks to work out, but the car is operational. I'm working on a detailed update. So much has gone on that I will break it down into two posts, one for Friday and another for Saturday.

Comment

Comment