Something random in 2017

Sorry, this update is kinda messy.

I always wanted a shortshifter, but not the hardcore one for race cars. Simple and easy using uniball and oem shifter parts.

[IMG]blob:https://www.flickr.com/db9b2db2-7bbe-4d75-9c79-fe6babb648e2[/IMG]

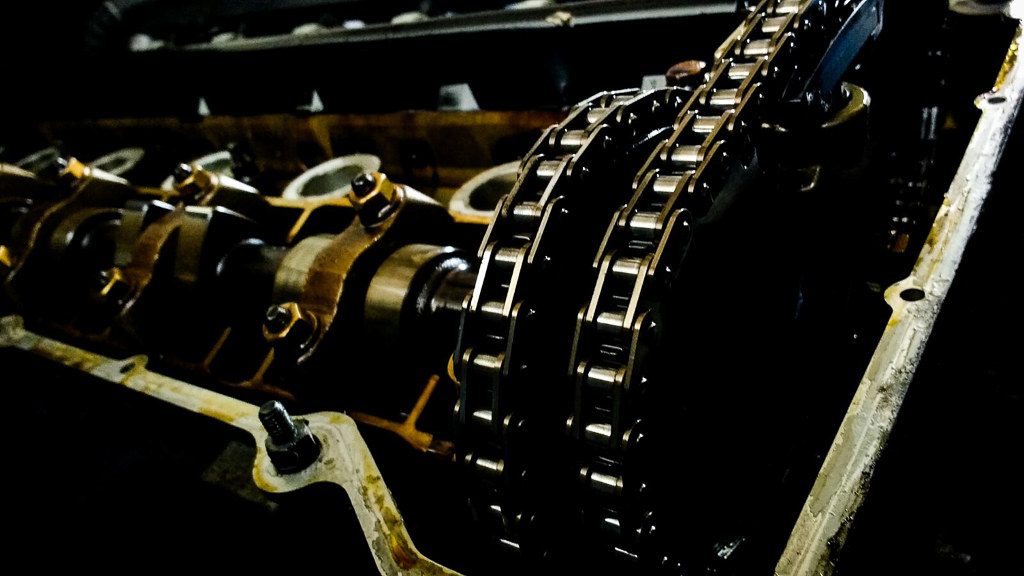

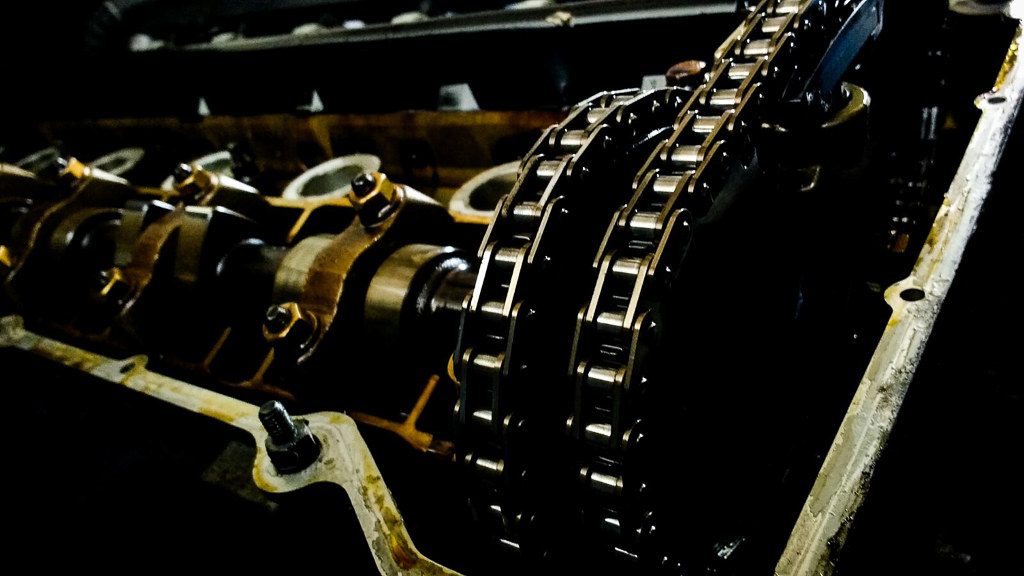

Maintenance. Fixed leaking from engine and other small things.

Lowered springs, new shock absorbers.

I h4te rust

Trying to save it, because its OEM

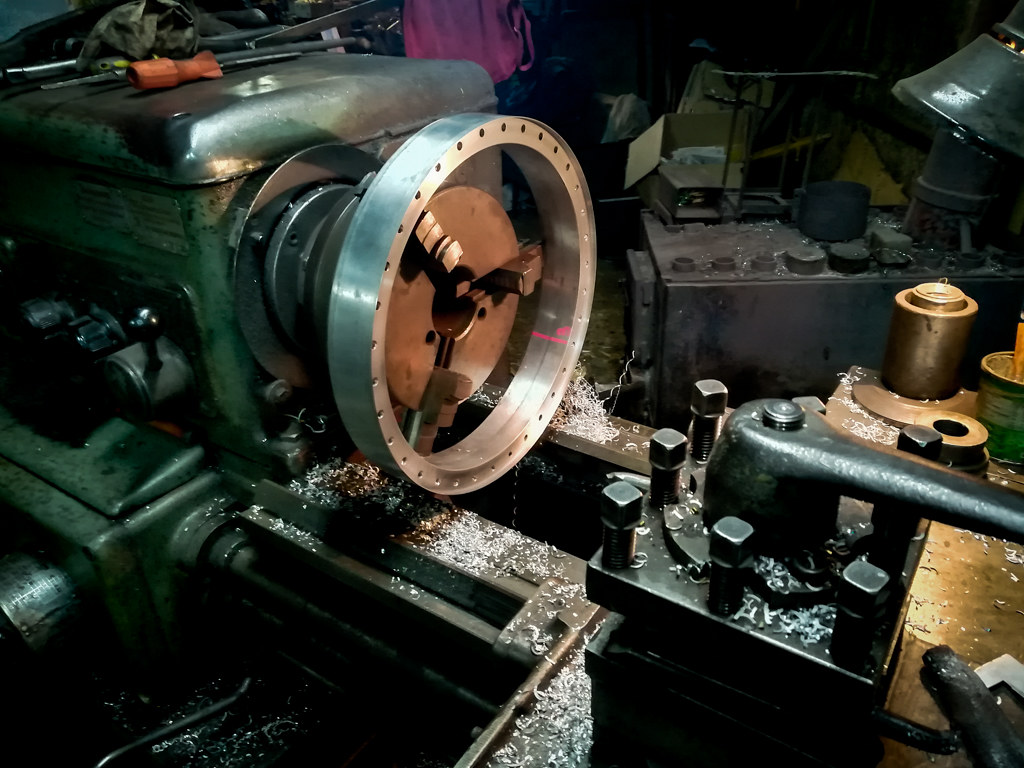

Later it was fully welded & grinded. No after pictures, but the result is in previous photoshoot pictures. Actually I like all that metalworking stuff.

Then, I really wanted to retrofit electric windows, but apparently they cannot be retrofited in my 520i. Such a sad story. But I had something in my mind. Found wiring harness swap from 525i. 518i, 520i and base models had 'low' wiring harnesses and 525i models and up, have 'high' wiring harness with comfort blocks and many more extras. How hard can it be?

Harder than expected to be honest. And this is just beginning.

New one.

Here you can see how long it took to do this job.

Also newer cluster with OBC display.

Also replaced white dash with black one. To be honest, this white interior is in kinda bad condition. White interior looks nice if it's in good condition. For now, it's just will be easier to find a good black interor & seats.

After many though days doing this swap, couldn't start the car. 525i actually was an automatic, so had to change relay, easy fix, but spent many hours to figure that out.

Happy days! First drive after 2 weeks of headache.

Bought interior parts from black interior - dark grey carpet, mouldings etc. Also found OEM Hella spoiler in junkyard, bought for 20 EUR. Rear electric windows and other small things.

Sorry, this update is kinda messy.

I always wanted a shortshifter, but not the hardcore one for race cars. Simple and easy using uniball and oem shifter parts.

[IMG]blob:https://www.flickr.com/db9b2db2-7bbe-4d75-9c79-fe6babb648e2[/IMG]

Maintenance. Fixed leaking from engine and other small things.

Lowered springs, new shock absorbers.

I h4te rust

Trying to save it, because its OEM

Later it was fully welded & grinded. No after pictures, but the result is in previous photoshoot pictures. Actually I like all that metalworking stuff.

Then, I really wanted to retrofit electric windows, but apparently they cannot be retrofited in my 520i. Such a sad story. But I had something in my mind. Found wiring harness swap from 525i. 518i, 520i and base models had 'low' wiring harnesses and 525i models and up, have 'high' wiring harness with comfort blocks and many more extras. How hard can it be?

Harder than expected to be honest. And this is just beginning.

New one.

Here you can see how long it took to do this job.

Also newer cluster with OBC display.

Also replaced white dash with black one. To be honest, this white interior is in kinda bad condition. White interior looks nice if it's in good condition. For now, it's just will be easier to find a good black interor & seats.

After many though days doing this swap, couldn't start the car. 525i actually was an automatic, so had to change relay, easy fix, but spent many hours to figure that out.

Happy days! First drive after 2 weeks of headache.

Bought interior parts from black interior - dark grey carpet, mouldings etc. Also found OEM Hella spoiler in junkyard, bought for 20 EUR. Rear electric windows and other small things.

I never liked them (spoilers).

I never liked them (spoilers).

Comment