Hello all, recently picked up a 1993 Rx-7 R1 this spring and have been working on it continuously since then (had it shipped from out of state). Plan is to shave the bay, decide on a widebody (already have the burnout kit but cant decide if I want to run it or not), and decide on a motor (already have the ls1 and t56).

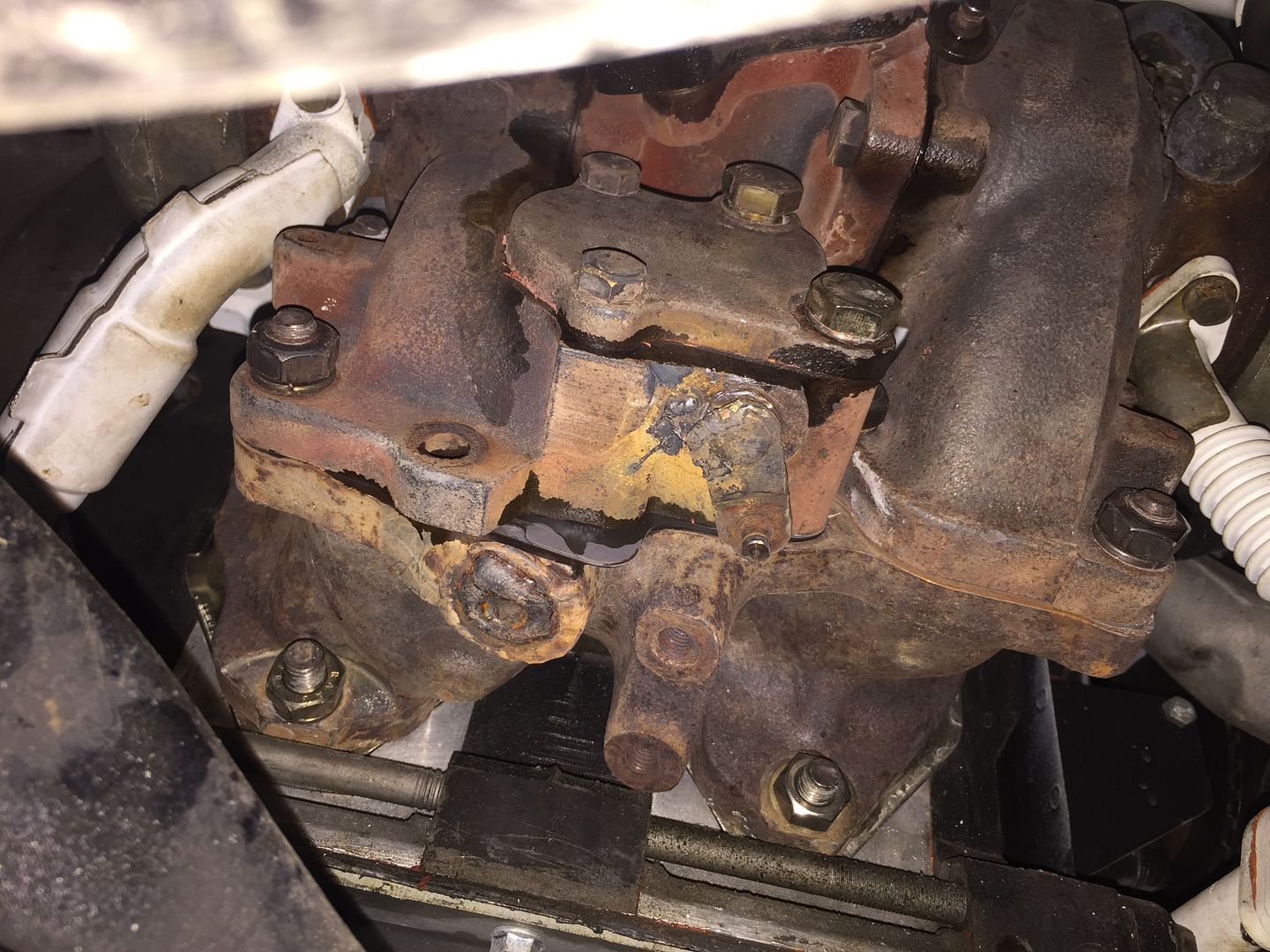

Not exactly sure on mileage because carfax shows 18x,xxx as the last mileage and the cluster isn't original to the car and shows 8x,xxx. I wasn't worried about mileage though since nearly everything was replaced (and I won't feel bad driving the car a lot and racking up the miles). Previous owner rebuilt the motor, made a vmount setup, installed ID 750/1000cc injectors, walbro 255 fuel pump, rebuilt differential, all new superpro bushings, os giken twin plate clutch, stance coilovers, haltech ps1000, 3" exhaust, ST sway bars, and a few other things. It came with a spare transmission and stock turbos as well. Oh, and it has work xt7 wheels which I will be selling here soon. I picked it up for what I thought was a steal, but upon getting the car here I feel it was still a good deal, but not as good as I thought. ( I knew I was taking a chance buying it without being able to see it)

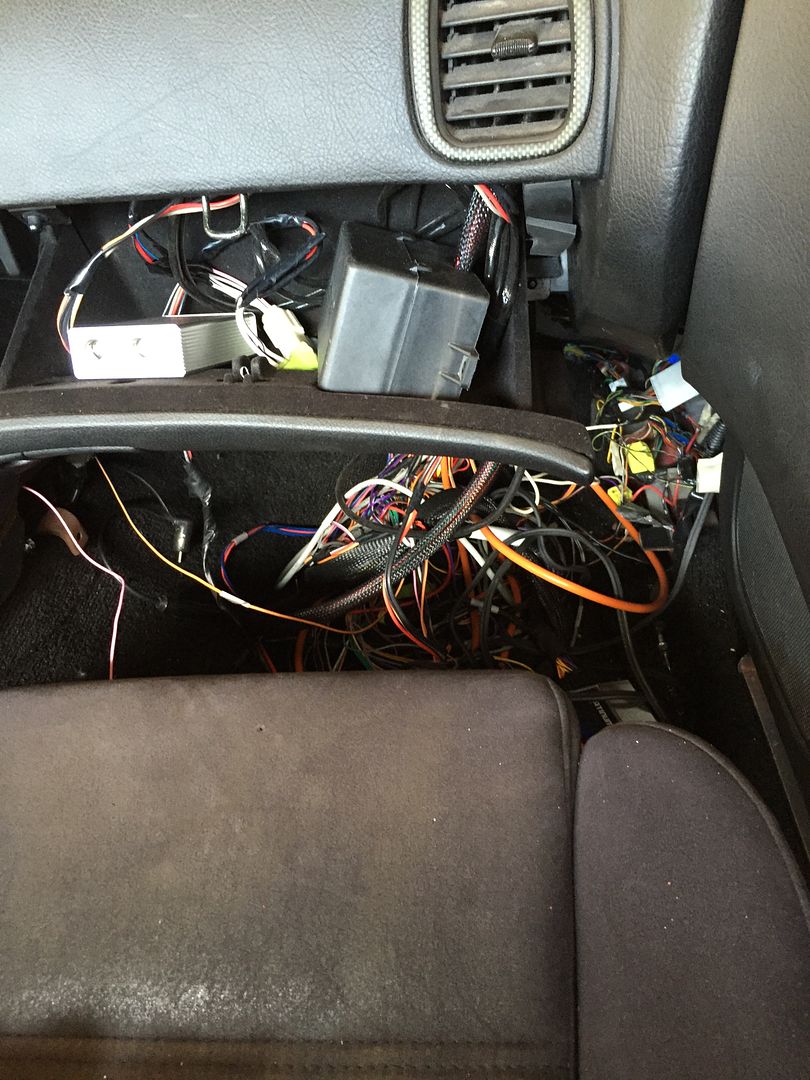

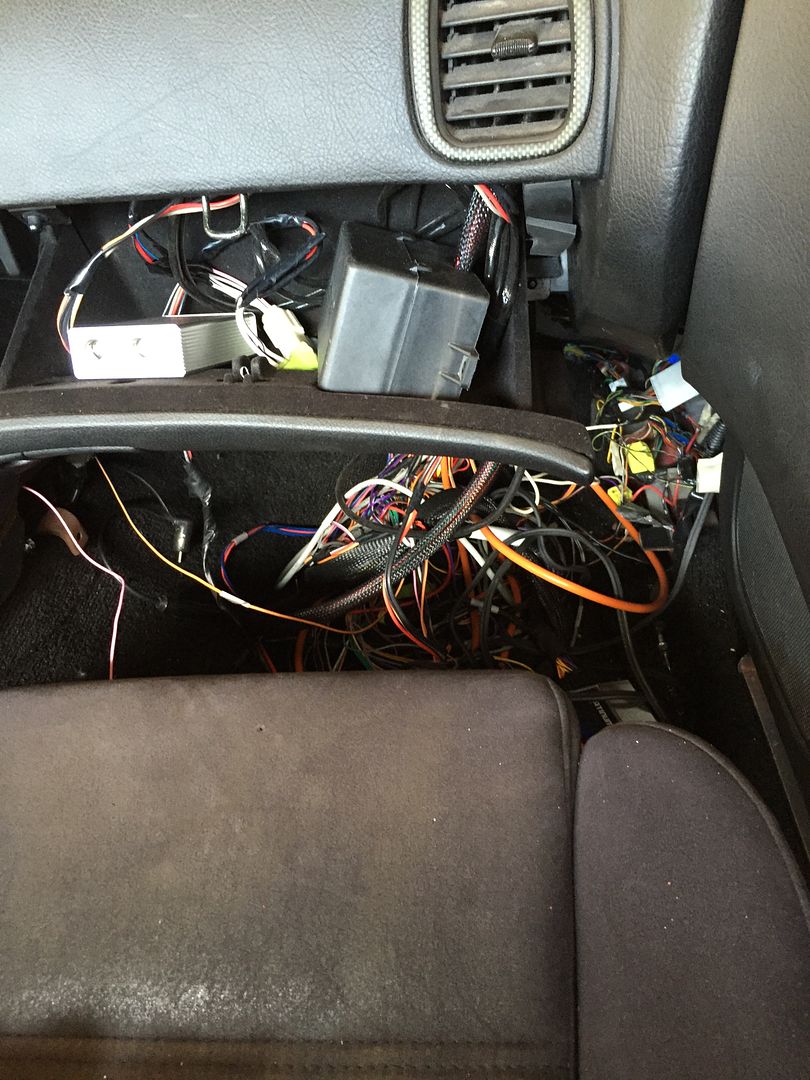

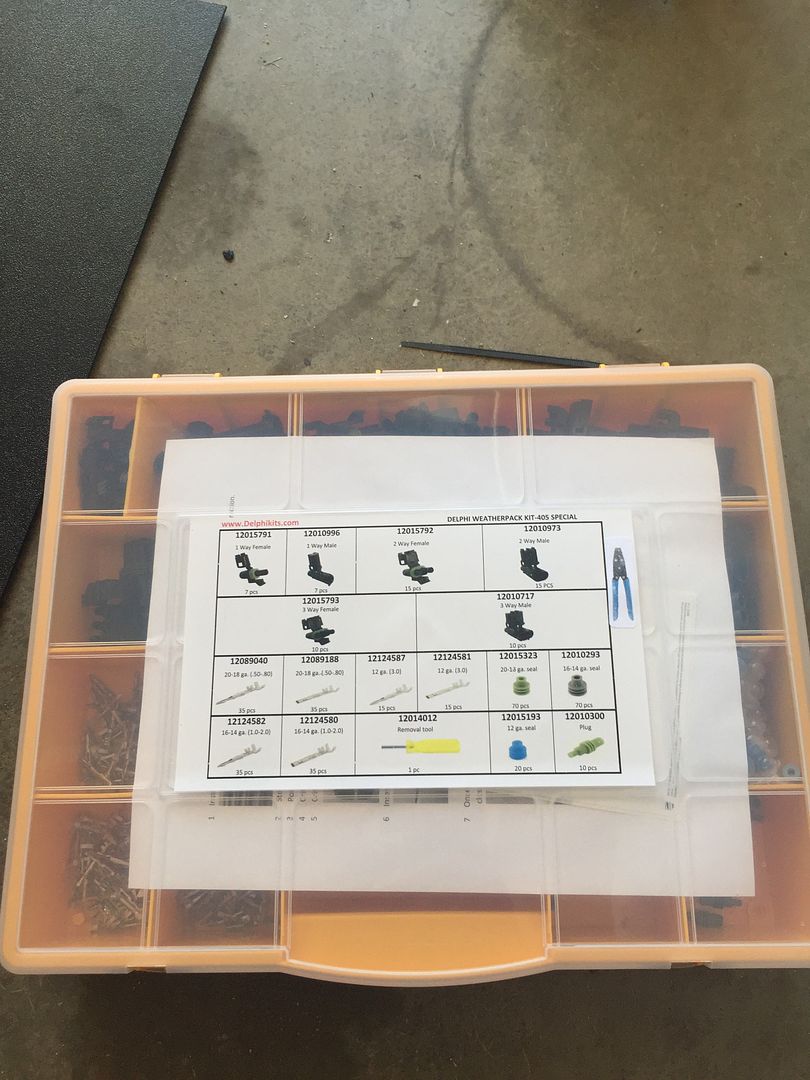

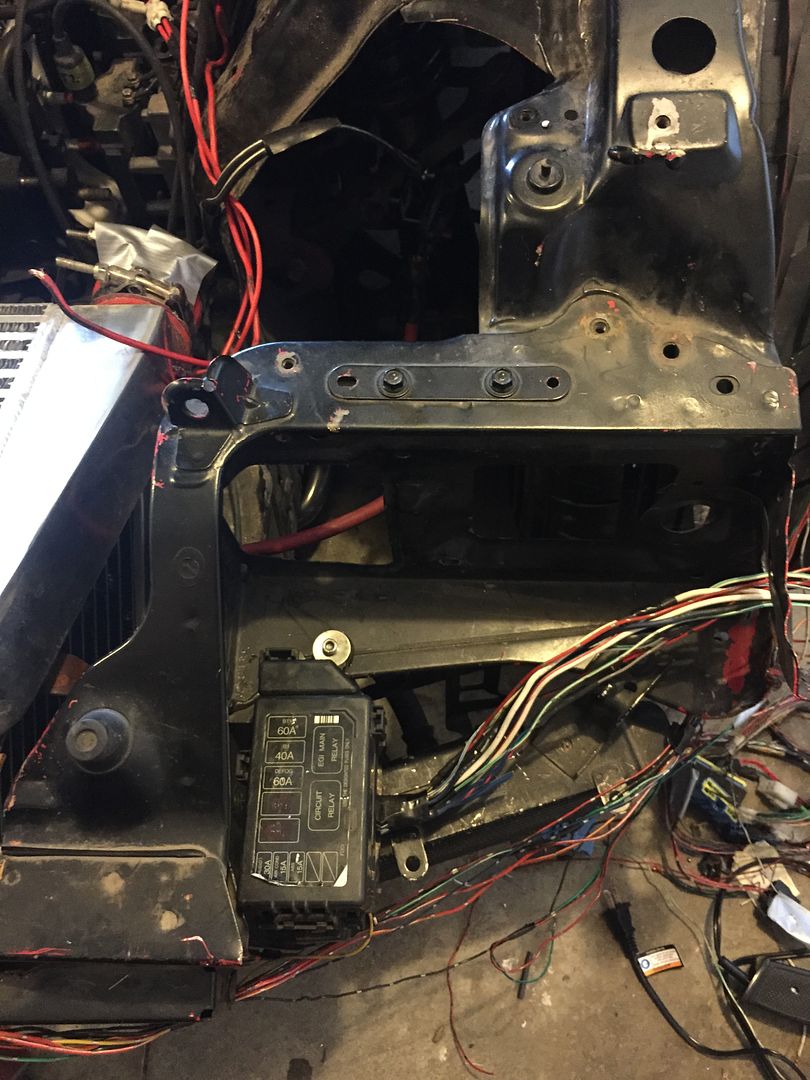

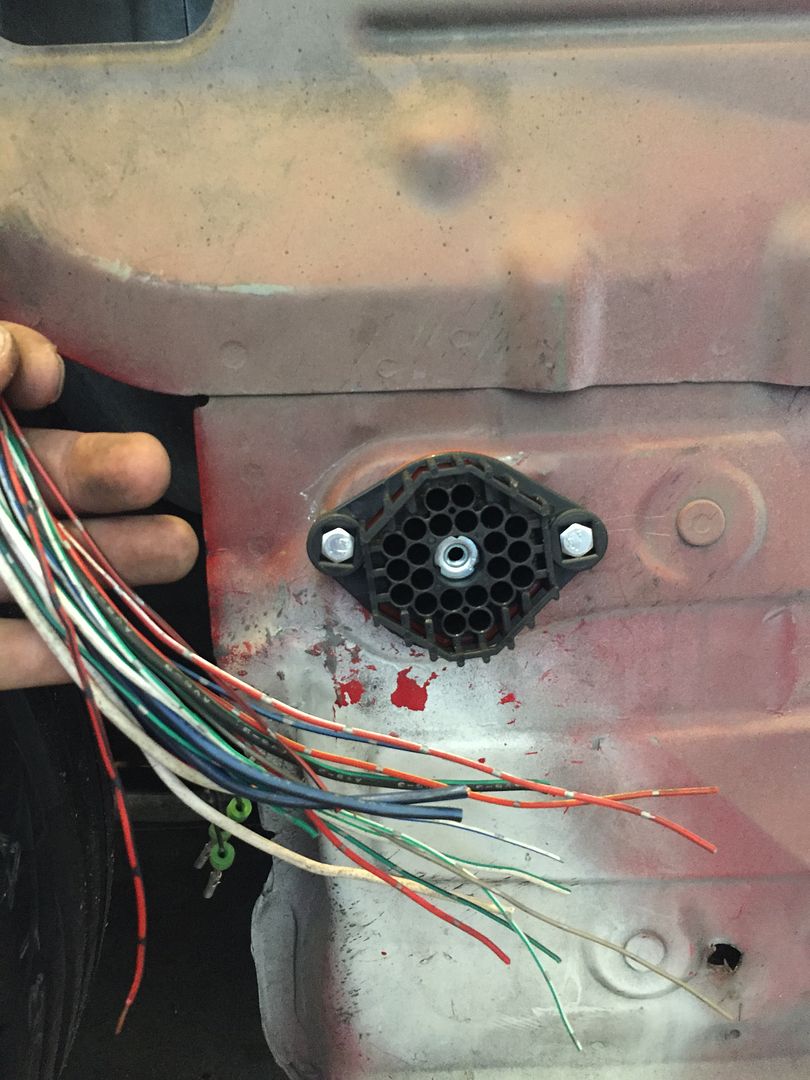

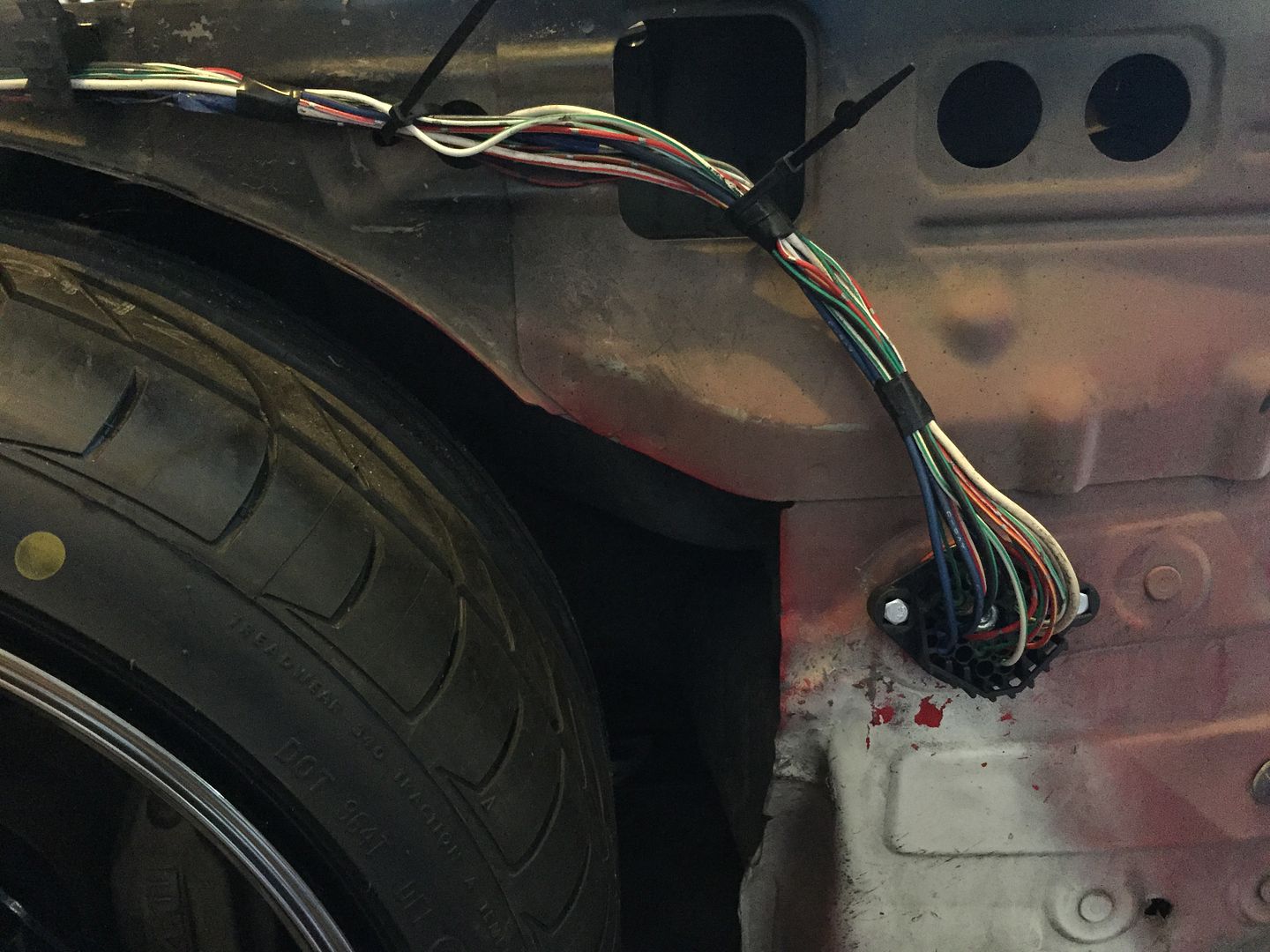

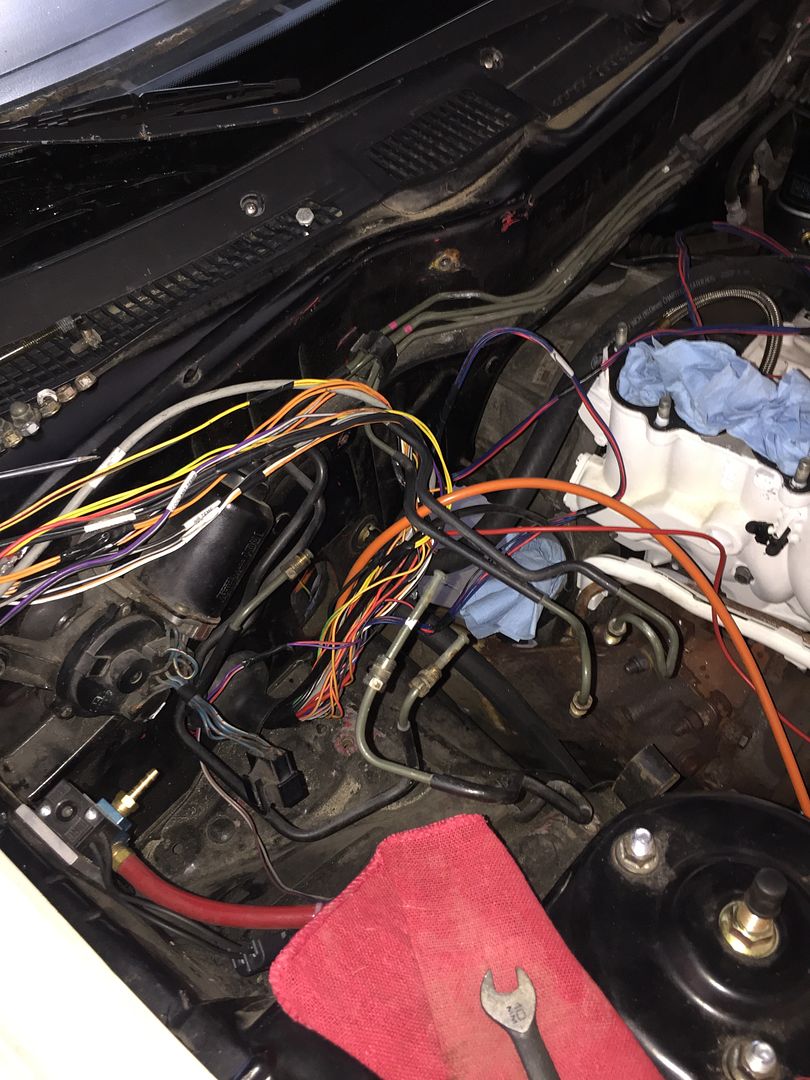

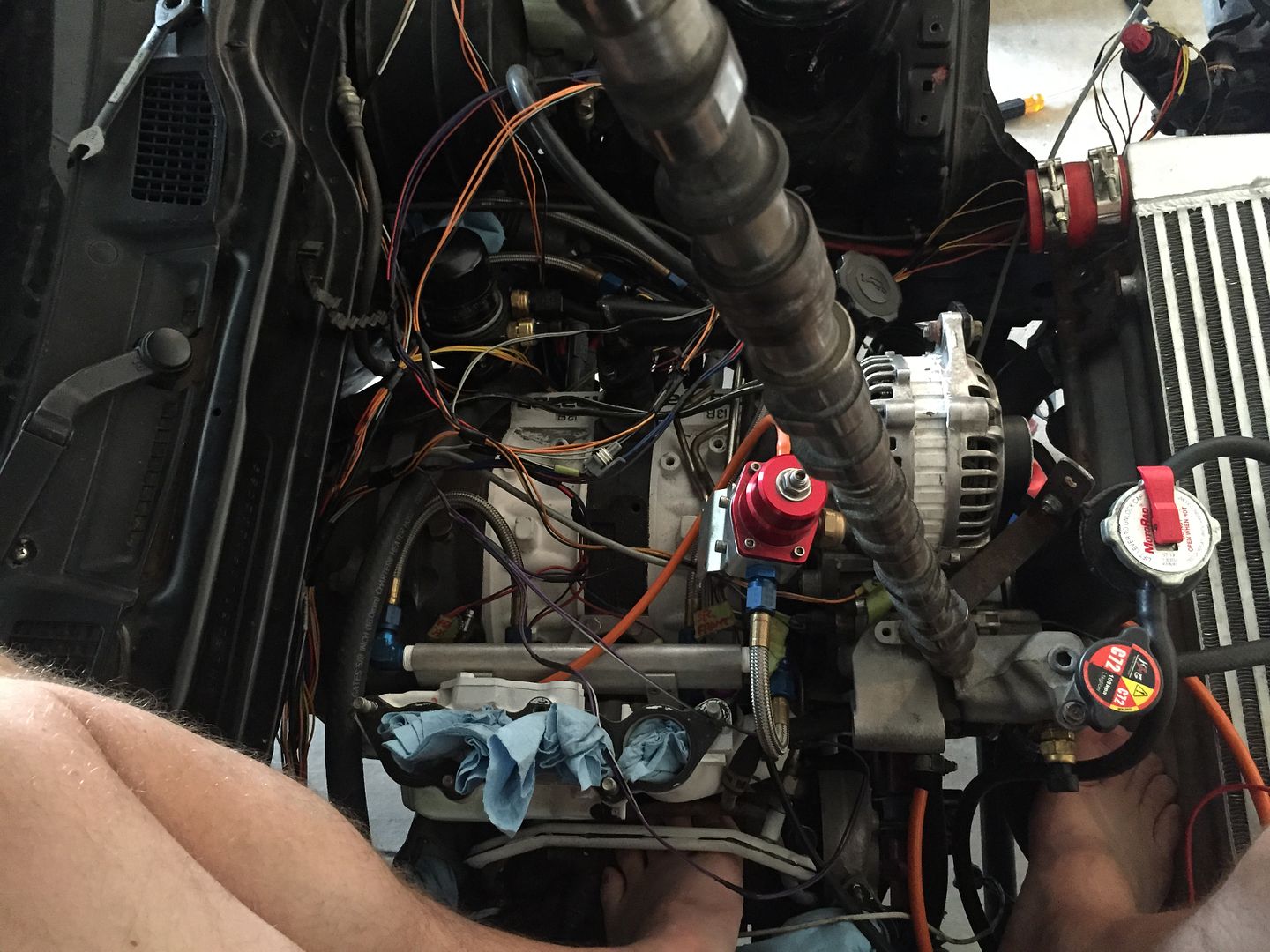

I knew it needed the wiring redone so I went ahead and ordered loom and adhesive lined heatshrink.

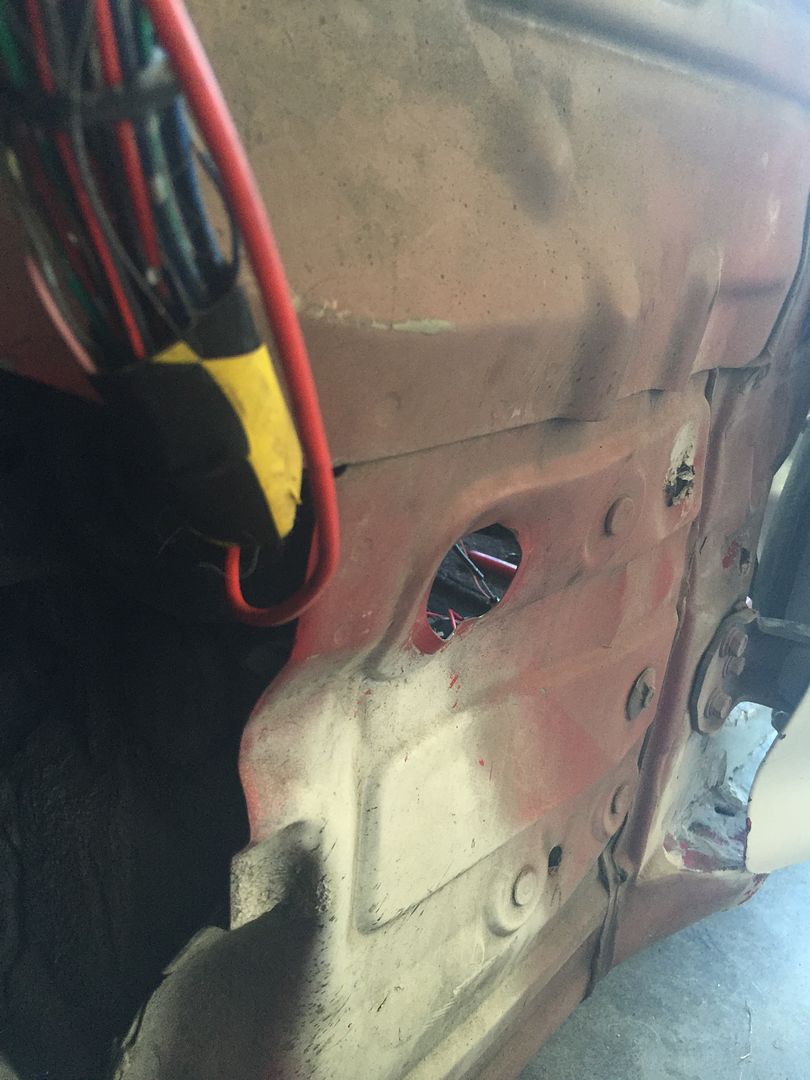

I drove the car from the trailer into my garage and started tearing it down (wiring was laying on the front tires, no way I was driving it).

Haltech wiring was just laying in the floorboard ( I knew this, hence I ordered loom before even getting the car in)

I was a bit surprised to find two different color doors

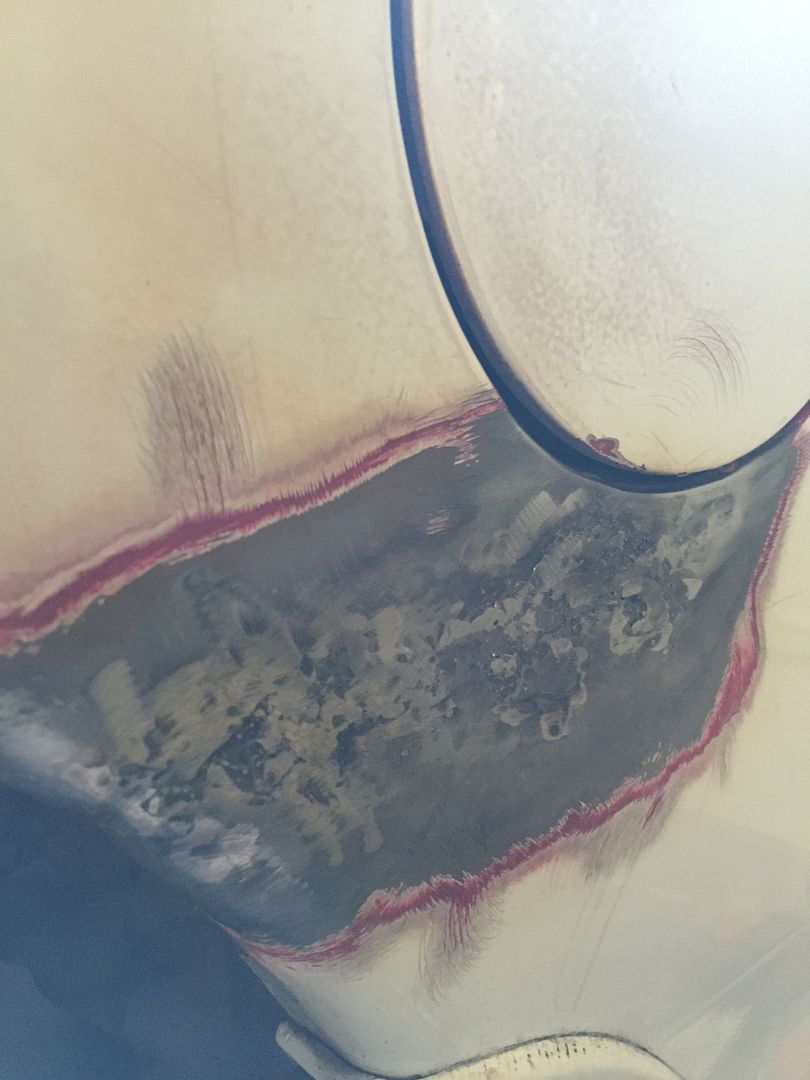

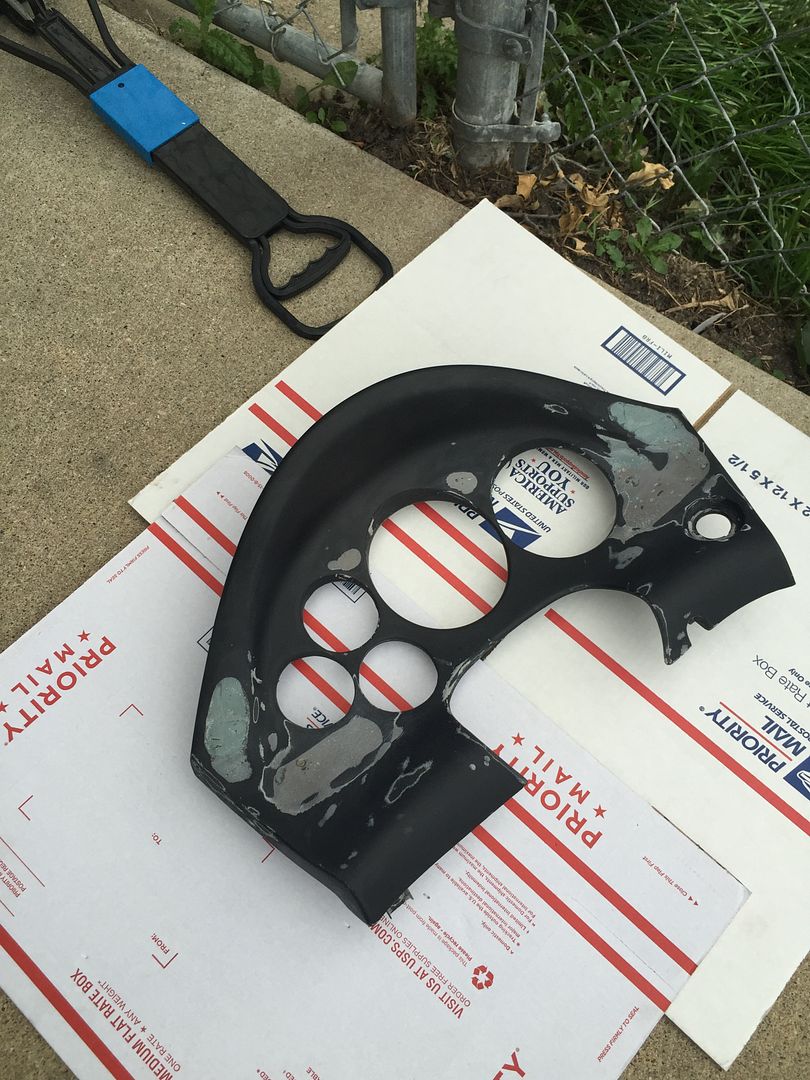

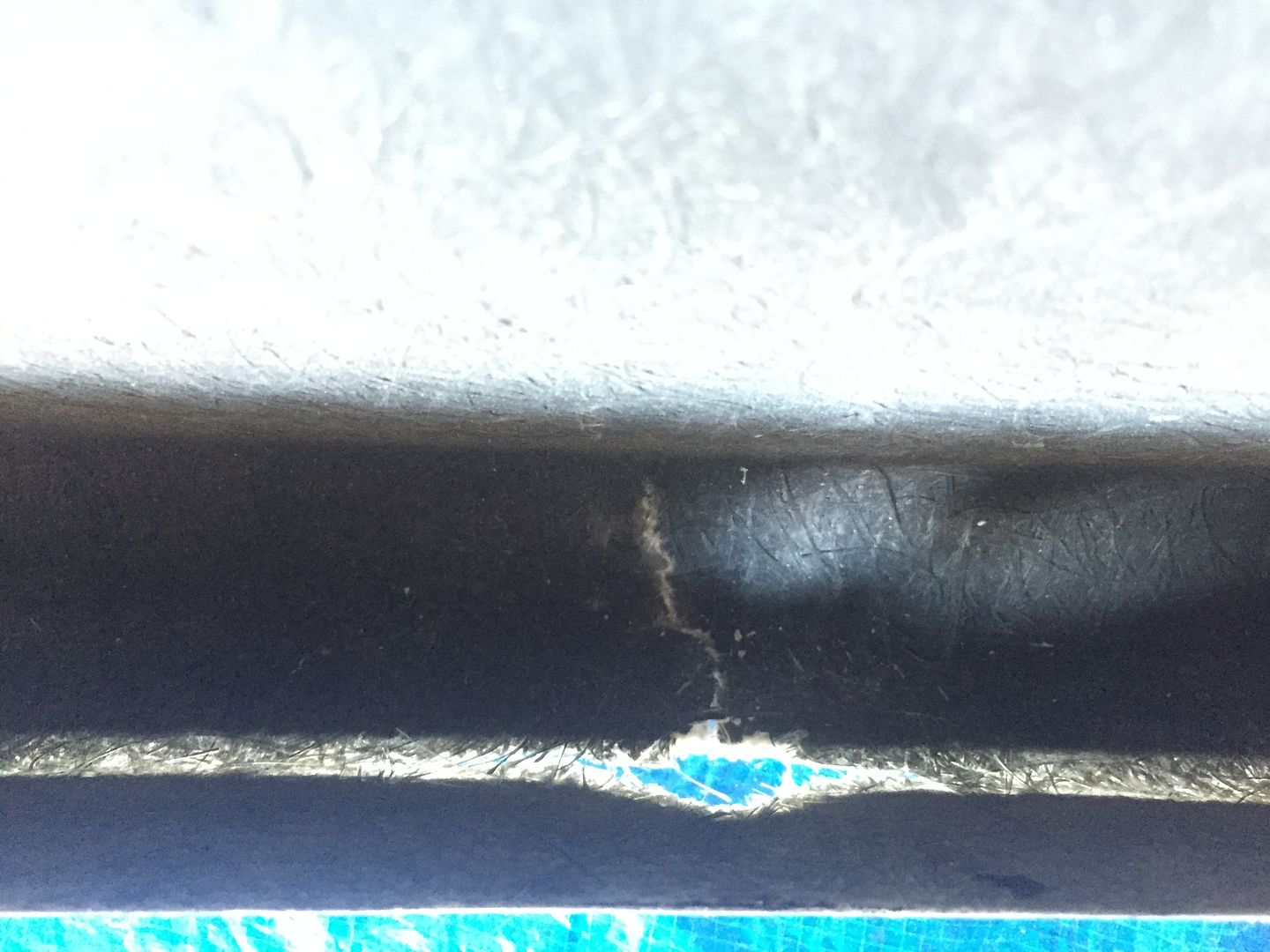

So I started investigating some more. The carfax showed clean, no wrecks at all. I knew it had recently clipped the wall at a track in Germany and was aware of that damage (for the most part), but the door threw me off. So I started investigating the side skirt area with a magnet and what do ya know, tons of bondo from some shitty body work long ago

So that sucked. I am going to strip down that whole area and pull the metal out as much as possible and then resmooth it with much less bondo. I recently started getting into bodywork as a side hobby (started making a widebody for my 1995 Eclipse GSX before I decided to part it out and buy this car) so this will give me the opportunity to delve into that a bit more.

Not exactly sure on mileage because carfax shows 18x,xxx as the last mileage and the cluster isn't original to the car and shows 8x,xxx. I wasn't worried about mileage though since nearly everything was replaced (and I won't feel bad driving the car a lot and racking up the miles). Previous owner rebuilt the motor, made a vmount setup, installed ID 750/1000cc injectors, walbro 255 fuel pump, rebuilt differential, all new superpro bushings, os giken twin plate clutch, stance coilovers, haltech ps1000, 3" exhaust, ST sway bars, and a few other things. It came with a spare transmission and stock turbos as well. Oh, and it has work xt7 wheels which I will be selling here soon. I picked it up for what I thought was a steal, but upon getting the car here I feel it was still a good deal, but not as good as I thought. ( I knew I was taking a chance buying it without being able to see it)

I knew it needed the wiring redone so I went ahead and ordered loom and adhesive lined heatshrink.

I drove the car from the trailer into my garage and started tearing it down (wiring was laying on the front tires, no way I was driving it).

Haltech wiring was just laying in the floorboard ( I knew this, hence I ordered loom before even getting the car in)

I was a bit surprised to find two different color doors

So I started investigating some more. The carfax showed clean, no wrecks at all. I knew it had recently clipped the wall at a track in Germany and was aware of that damage (for the most part), but the door threw me off. So I started investigating the side skirt area with a magnet and what do ya know, tons of bondo from some shitty body work long ago

So that sucked. I am going to strip down that whole area and pull the metal out as much as possible and then resmooth it with much less bondo. I recently started getting into bodywork as a side hobby (started making a widebody for my 1995 Eclipse GSX before I decided to part it out and buy this car) so this will give me the opportunity to delve into that a bit more.

Finally! I have had the worst luck with these wheels. The first pair I got was damaged during shipping and I had to wait 3 months to get new ones. The second set I got was damaged by the tire shop the day I got them (after the 3 month wait). One tire shop wasnt going to replace them because they said it wasn't them that caused the damage....huge ordeal. Anyhow, they replaced the wheels and I had them shipped to a friend in Vegas to have the tires installed so there wouldnt be any issues with mounting again.

Finally! I have had the worst luck with these wheels. The first pair I got was damaged during shipping and I had to wait 3 months to get new ones. The second set I got was damaged by the tire shop the day I got them (after the 3 month wait). One tire shop wasnt going to replace them because they said it wasn't them that caused the damage....huge ordeal. Anyhow, they replaced the wheels and I had them shipped to a friend in Vegas to have the tires installed so there wouldnt be any issues with mounting again.

Comment