I was warned ahead of time: “Don’s shop is going to be a mess.” There’s undoubtedly a dichotomy that exists between the prim and proper white-walled race shops that focus on organization and detail work, versus a shop more akin to my own: tools stacked on any available surface, and a flagrant disregard for cleanliness in the name of progress. I’ve been told more times than I can count, “If a shop is dirty, it means things happen there. It’s a sign of success.” At least, I am somewhat sure others have said it to me as much as I mutter the words to myself. If such a mantra is to be believed, however, then Don Zemina’s Motor Machine clearly stands as something remarkable. Behind the walls of the Motor Machine Super Shop, quite literally thousands of engines lie in wait, begging for their turn to be worked by the man himself. In the heart of Carmichael, California, Motor Machine stands as a monument to a slowly dying craft: a chapel of speed, a church of high compression, a cathedral of engine building with no holds barred for doing things the right way. It’s been this way for decades, and Don’s 12,000-square foot facility shows it.

If the Motor Machine name rings a bell, it’s thanks to Riley Stair’s ’70 Trans Am, recently featured as one of the all-time best feature cars to ever hit the homepage. Beneath its paper-thin featherweight fiberglass hood, and tucked behind its snakes-nest bundle of 8-to-1 headers lies one of Don’s wildest creations: 400-cubic inch small block LS built to turn 10,000 RPM and and turn out 1,000 horsepower at the crank, naturally aspirated, thanks to 16.25:1 compression and methanol as a choice of fuel. The motor itself leaves nothing to be improved upon and pushes the LS platform to the limit of logic, but its builds like these that Don and Motor Machine have built their name upon.

Riley and I arrived at the shop bright and early, present to put the Trans Am on the dyno for some further tuning and tweaking by the Don himself. Don tunes his creations as well as he builds them, and with such a high-strung balls-to-the-wall engine at hand, there’s no chance Riley would trust anyone else on earth. As Riley strapped his pony car to the Superflow dyno, I began to look around, eager to see what was hidden behind the walls of such a place. I grabbed my camera and began the hunt. But if your vehicle is in desperate need of repairs, looking for a reliable shop, such as an auto collision shop, for instance, may be necessary.

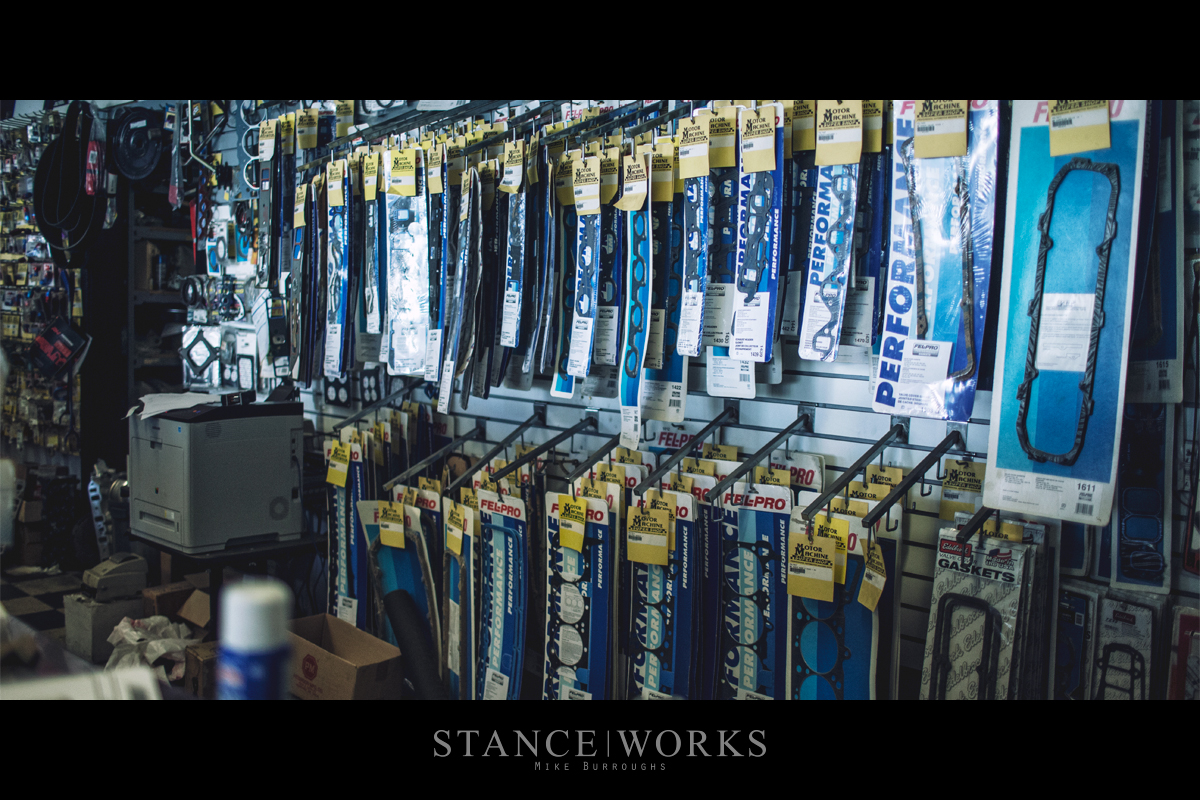

I stepped inside the lobby and was warmly met by a storybook speed shop storefront. Parts lined the walls and aisles, some fresh from the supplier and others present for years if not decades, waiting for the right soul-in-need to come by. Somewhat stuck in decades passed, it felt oddly familiar and nostalgic. As the calendar has turned, Motor Machine’s firmly planted roots have kept it from giving way to any outside influence. With every AN fitting imaginable in stock, every Holley carburetor gasket and jet ever made, and every combination of distributor, plug wires, and ignition components sitting on the shelves, its clear Don caters to his own roots: the American V8. It’s far from all he does; if it has pistons, he can build it to the nines, but it’s the thumping 8-cylinder that he’s built his name around, and it’s what he’s capable of doing to them that brings folks from across the country to Carmichael, California.

I browsed around the storefront, admiring the bits and pieces that lined the shelves, but it didn’t take long before curiosity got the best of me. With the blessing to explore the labyrinth of rooms, hallways, and paths formed by stacked engine blocks, I made my way slowly towards the back of the shop.

Just outside of view, through a door at the back of the dyno room, things began to unfold. A slew of cars were shoehorned into a long bay with several lifts: ’60s Camaros, a Chevelle SS, and even a C10 were all parked, waiting for odds and ends to bring them to life. More impressive, though, were the engine blocks that lined the walls. Hundreds of them, stacked to the ceiling, each apparently memorized by Don’s encyclopedic memory. “There used to be a lot more,” Matt, Riley’s father, told me. “He filled a 40-foot dumpster with blocks not all too long ago. We’re just admiring the remnants.”

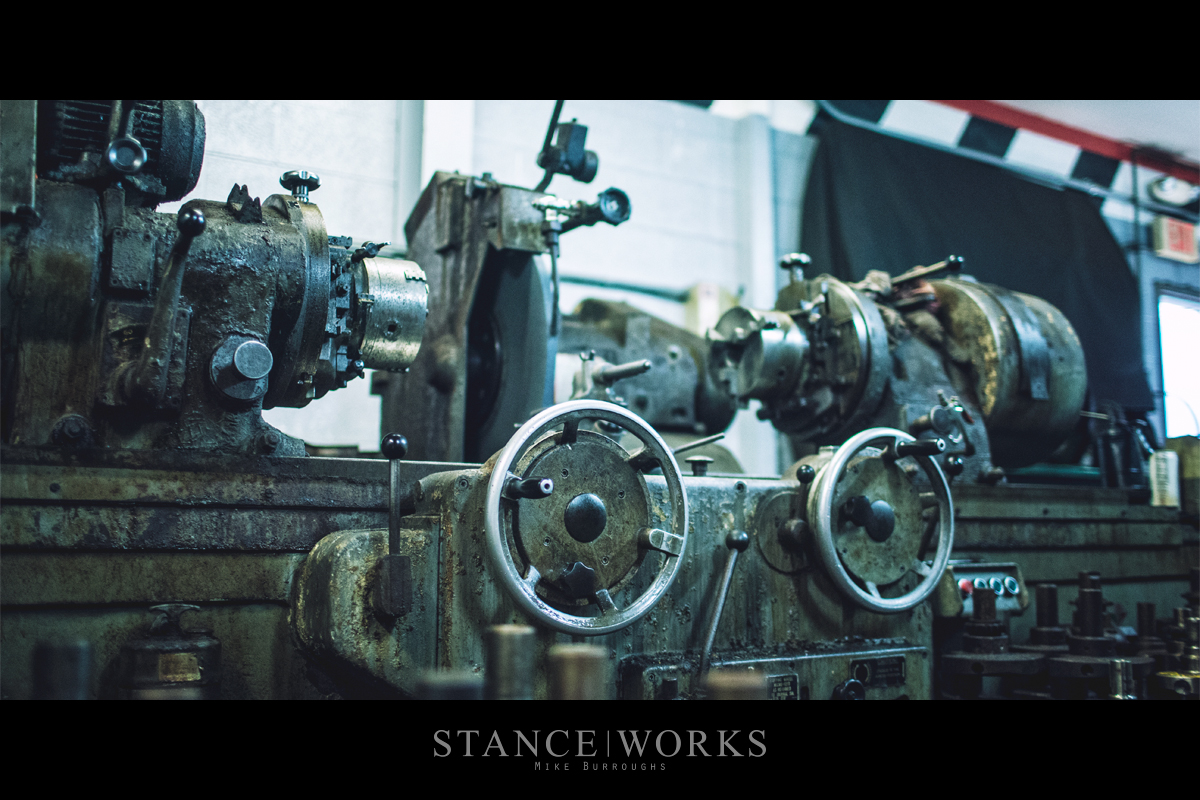

It was clear, however, that despite the recent clear-out, the shop was still chaotic. Making my way from one room to the next, I found myself snaking through a pathway lined with engine blocks and boxes of rods and pistons. The perimeter walls, at least 15′ in any direction, were inaccessible without climbing over stacks of engines more daunting than the Himalayas. Access to the machinery, though, was possible, and keeps the steady stack of motors moving through the building.

How it stays organized is beyond my best guess, but there was something immeasurably charming, and promising too, that permeated the insanity. Shelves of cylinder heads, hundreds upon hundreds, made aisleways that snaked further and further into the building. Each was head marked with paint and a name, waiting to get the Motor Machine treatment.

Eventually, the blocks turned to crankshafts, suspended on custom racks by the hundreds. Two crank turning and balancing machines sat in the back corner of the building: more machinery clearly used day in and day out for decades, all in the name of building or rebuilding NorCal’s engines.

As I continued to work my way through the building, I witnessed each step of the process. A block sat perched in the 5-axis CNC, receiving a who-knows-what level of work, but fit for the standard prowess of a Motor Machine engine. Brad was busy boring blocks while Rick assembled cylinder heads, and Mike prepped for final assembly. As a team of four with Don, they keep the engines turning, literally and figuratively, and somehow through the chaos, greatness is born.

Engines like Riley’s are completed and sent out on a daily basis, each one given new life, or build from nothing to become a new heart for a project. The foundation for Riley’s engine is a 400-cubic inch LSX Dart LSNext2 iron block. Perched atop the banks is a pair of Dart 368cc 10-degree canted valve heads, which have been loaded with Victory titanium valves and PAC springs with titanium retainers. Below are .970 solid roller lifters, custom tapered 7/16 pushrods, a custom ground Cammotion billet camshaft, Jesel shaft rockers and a Jesel belt drive. A billet no-drill balance Callies crank shaft, GRP aluminum rods, and ARP fasteners throughout keep the impressive build going. To finalize the internals, custom 16.25:1 compression JE pistons were built and installed. Up top, a pair of Holley EFI fuel rails supply the fuel which passes through Billet Atomizer 225lb injectors. A FAST 4500series thin throttle body sits atop a custom Dart Intake manifold to supply air to the beast, and the system is controlled by a Holley Dominator ECU.

Don is no stranger to over-the-top engine builds, and with the “Horsepower Wars” driving power numbers up higher than ever before, 2000 horsepower is 1999’s “700hp.” Forced induction or Naturall Aspirated, Don can do it all, and with such an intimate knowledge and understanding of the engines he builds, there’s a reason folks head to him for tuning at any cost.

I returned to the Dyno room, having come full circle, through both the engine building process and the shop itself. Don returned shortly after, having finished discussions with a customer about an engine build-to-be. Don’s a no-nonsense kind of guy: abrasive on the surface, with no fear to unapologetically tell it like it is, but with an immense wealth of knowledge and a desire to do things the right way, the first time. There’s no room for mickey-mousing engine repairs and builds, and he holds a specific standard to ever part and piece that leaves the shop. If you bring him junk, you’ll leave with junk, and perhaps a bruised ego – but if you come to Motor Machine wanting an engine built right, there’s no alternative, period.

Don placed his laptop on the roof of the Trans Am and the dyno session began. The Trans Am’ exhaust pierced the walls of the shop, and like clockwork, every customer inside comes to peek to see what the commotion is all about. The Trans Am received another bout of tuning, and with more on the table after some hiccups are solved, the Trans Am will make a return once more. With Don’s engine work gracing Riley’s C10, his Datsun, and now the Trans Am, and with how wildly fast yet bulletproof each one is, it’s a clear indicator as to why Don earns himself life-long customers. In fact, he’s earned another. When the itch strikes to build a big turbo LS, I know where to go, and now you do too. And with any luck, maybe you can take a look around too. As one of the most chaotic yet incredible shops I’ve had the chance to visit, it’ll be a story I’m eager to share for years to come.