Over the past few years, there has been a influx into the world of aftermarket automotive centered around wheel fitment. It’s not that wheel fitment is a new concept, or that’s its been re-invented, but rather has evolved into places that hold no bounds. Wheel companies have progressed to offering aggressive fitments tailored to the millimeter of a customer’s liking, but typically that means shelling out a few more bushels of wheat then you might be accustom to. Well, put the sheerer back in the shed, because I’m here to show you how to look dapper without cutting back to 2 meals a day… enter stage left: Adaptec Speedware.

Adaptec Speedware is a company that has become synonymous with quality and attention to detail when it comes to the world of wheel fitment. They have been focused not only on making your wheels fit to your liking, but on ensuring that you can run whatever wheel your heart desires. Land Rover wheels on a Volkswagen? No problem. Porsche Twists on a Bimmer? Psssh… easy. Their knowledge is their greatest asset in helping you acquire that perfect fitment with the wheels you have always dreamed of.

The reality is, Adaptec Speedware has been so successful over the past few years that their only issue was turning product around quickly enough to meet the overwhelming demand. I got even better news for you, because thats a thing of the past. Adaptec Speedware has recently been acquired by the most efficient, in-house manufacturer of adapters and spacers in America, Motorsport Tech. That’s right, they have aligned forces to bring THE best adapters and spacers money can buy matched with quality materials and an efficient and timely manufacturing system. Don’t believe me? All you had to do is ask.. let’s dive in for a closer look:

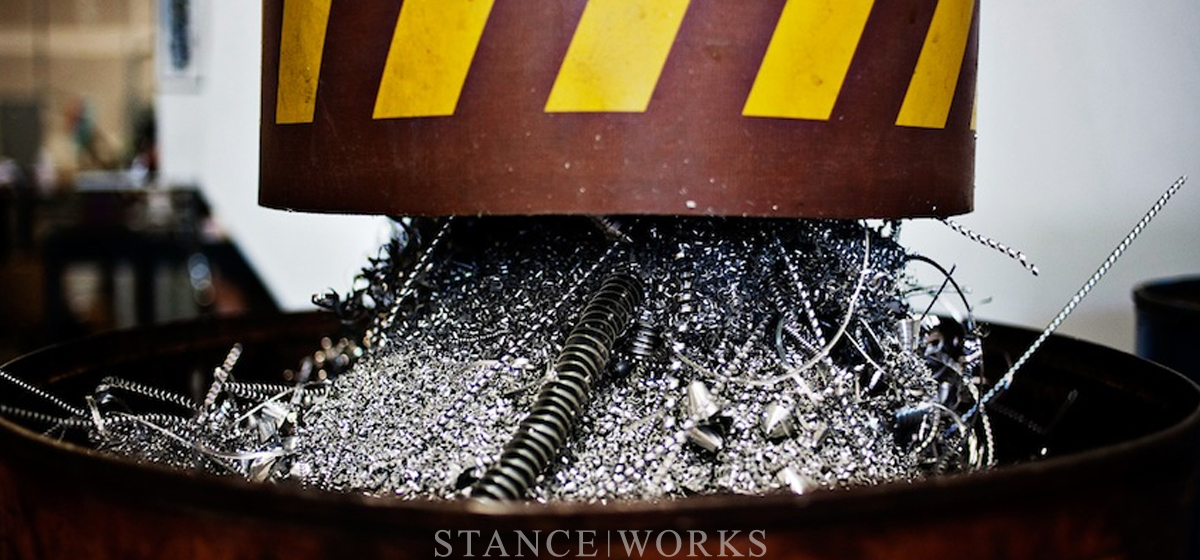

What you are looking at is the birth of an adapter / spacer. This is raw material that is Alcoa sourced 6061-T6 aluminum, the best that you can get your hands on in the states. There is no mucking about or cutting corners right from the start.

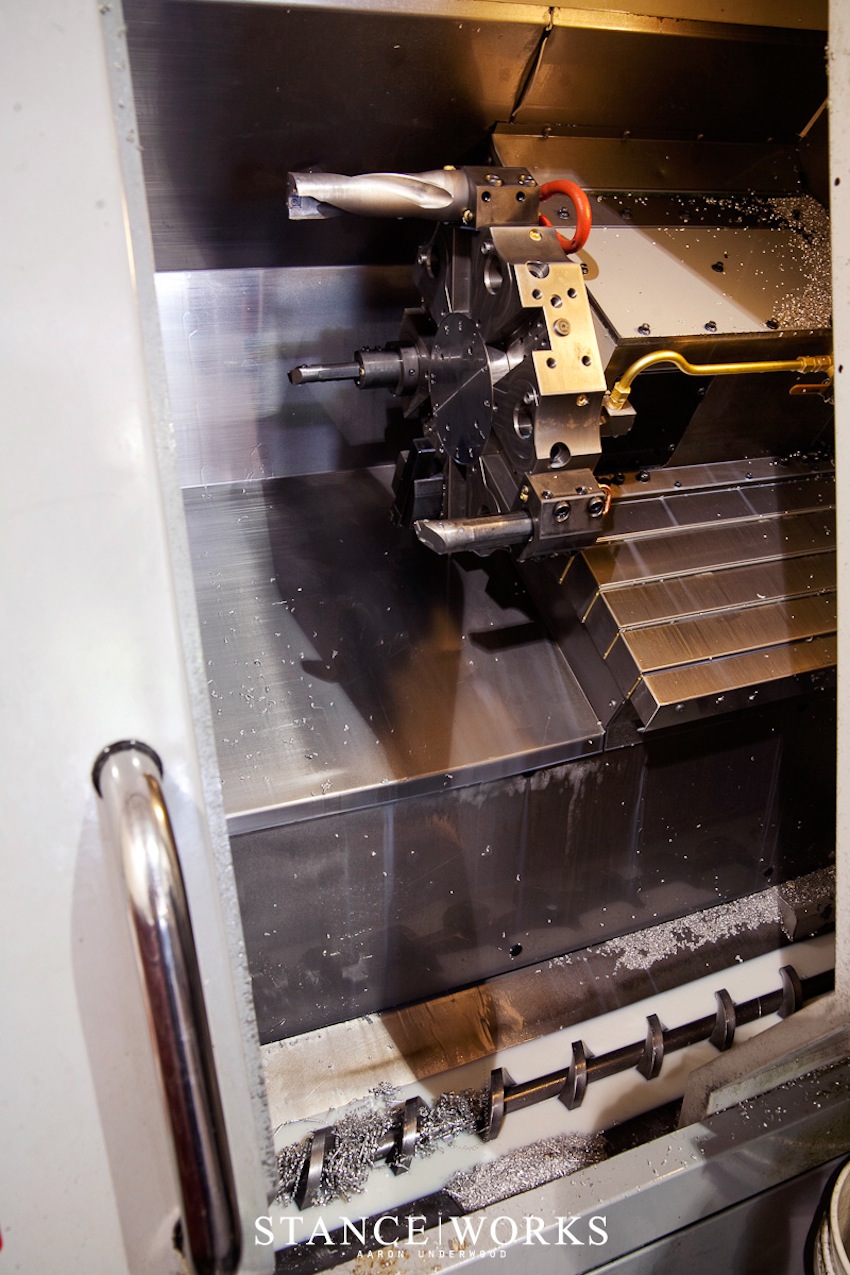

Once the right size raw blank is chosen, it heads over to this impressive piece of kit. This bad boy is an American manufactured Haas CNC Lathe… yeah we are going there.

The raw material is then placed into the lathe, where it begins to shave out the center bore and then proceeds to cut the outer diameter to the requested specifications. Looks like a torture device doesn’t it? Yeeesh…… moving on.

The freshly cut aluminium is taken over to have appropriate tooling put in place in preparation for bolt pattern cutting on the mill.

Now, when I say “mill” one would assume an operation that caters specifically to adapters and spacers would have something that was pretty haggard, and about 30 years old. This is not the case with these guys. They believe “quality” needs to be more then a pick-up line. This is a Haas 5-Axis Mill that has the capacity to produce seemingly perfect spheres and has tolerances as tight as + or – .002. You still with me?

Then let the education continue. Once the tooling is placed on the individual pieces, the mill begins its work on a full set of adapters. Beautiful isn’t it?

Hang on, we aren’t done yet. Once the bolt-pattern is milled, it’s off to the press where the adapters are cleaned, de-burred, and the proper studs are pressed in. For you hardware nerds out there, Adaptec only uses the highest quality studs and hardware, grade 10.9 Bimecc. For the non-nerds out there, that translates to “really-REALLY good.”

Last step is final assembly of hardware, packaging and shipping… to anywhere in the world. Now you might be asking yourself, “but Ben, I live in a small fishing village off the coast of Iceland.. are you sure ‘anywhere’ in the world?” My friend, you too can own a set of Adaptec Speedware adapters because they have already sent orders to 60+ countries this year alone.

So here is the long and the short of it: If you want to see your wheel fitment dreams come true without selling off parcels of farmland and shelling out clams you wanted to cook instead of trade, these are the guys to call up. You will have peace of mind knowing with full knowledge that these parts are made with quality first and gimmicks never. They eat and breath metal shards with smiles on their faces to ensure your utter satisfaction. Larry, Junior, Josh, Craig, Nick or Brad; any one of them is ready and willing to help you make wishes become realities.

A special thank you to Aaron Underwood for capturing the content for this article. You can find more of his work via Underwood Photography.